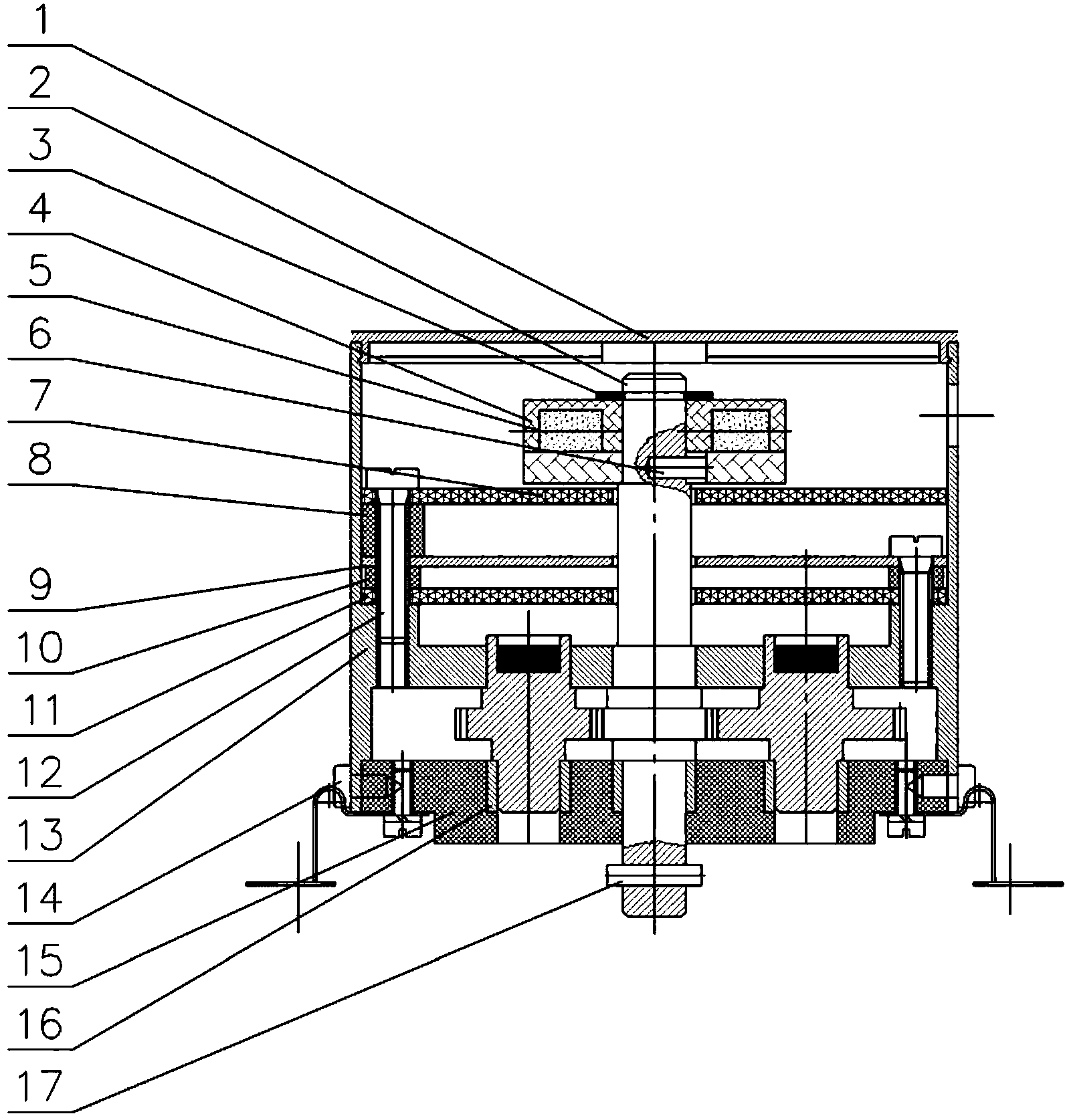

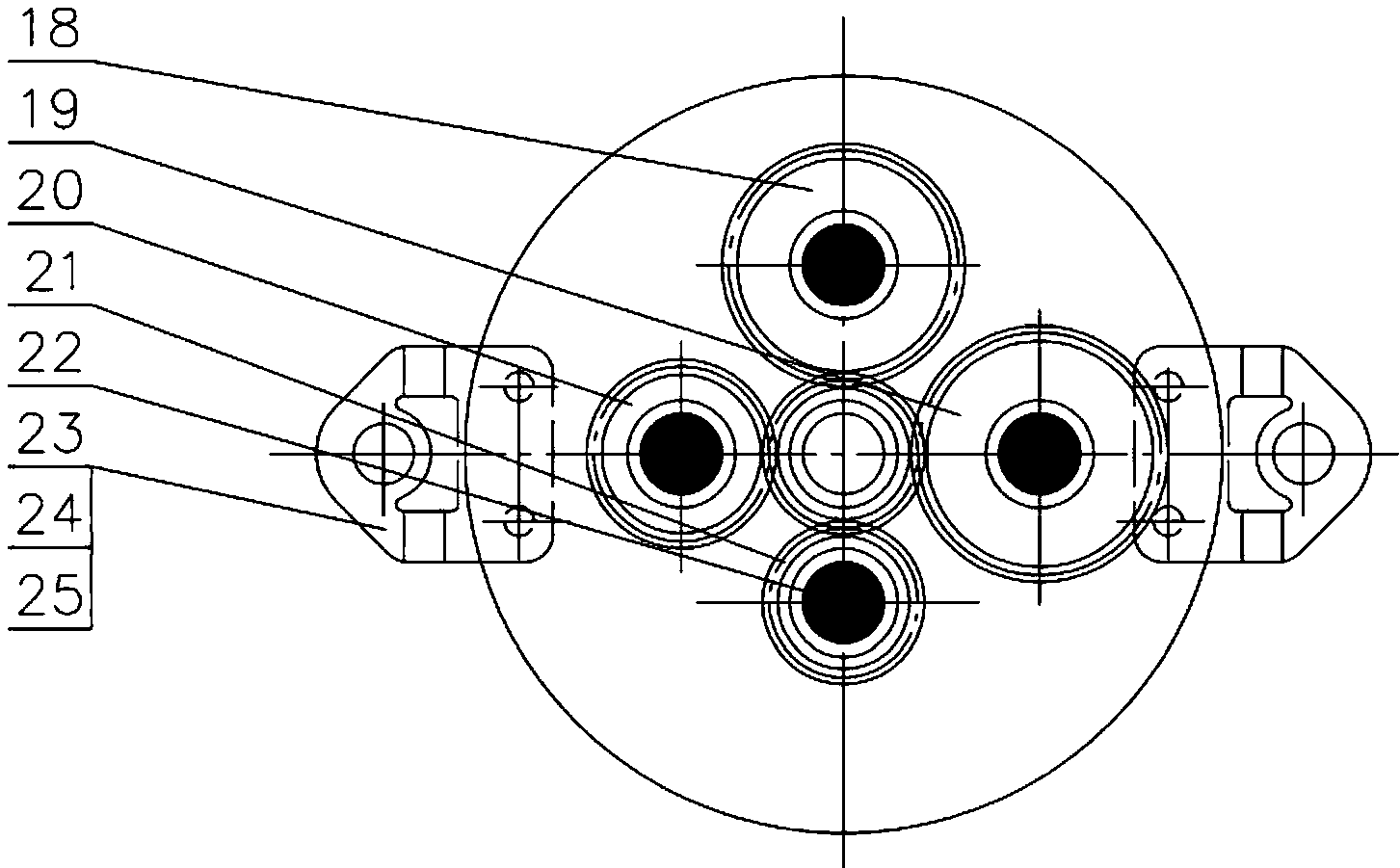

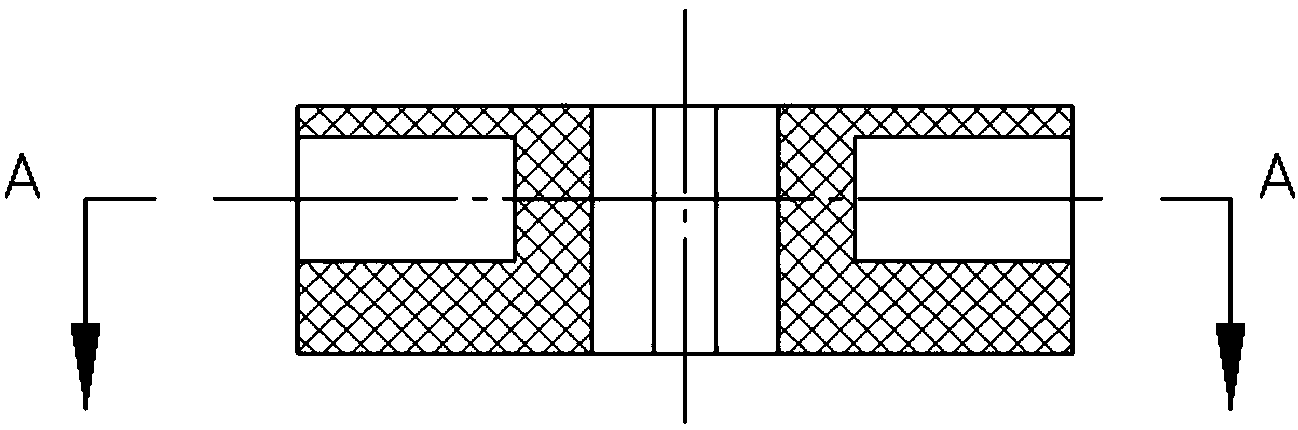

Position detection device

A detection device and encoder technology, applied in valve devices, valve operation/release devices, valve details, etc., can solve problems such as inability to locate accuracy requirements, position misalignment, and valve damage to electric devices, and achieve extended position detection and reliability. Display time, improve equipment reliability, and ensure the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0030] Embodiment 2: On the integration of the structure and circuit board layout of Embodiment 1, when the main control processor processes the data of the magnetic force line induction sensor and the magnetic pulse induction sensor, it adopts the position of collecting the two when the main power supply exists. The information is stored, and then the position information of the magnetic force line induction sensor is used as the main position information, and the information of the magnetic pulse induction sensor is used as auxiliary information. After the magnetic force line induction sensor fails, the information of the magnetic pulse induction sensor is automatically switched. When the main power supply does not exist, only the magnetic pulse induction sensor is collected for display and position judgment. After the main power supply is restored, the information of the magnetic force line induction sensor is used to calibrate the information of the magnetic pulse induction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com