A energy-feeding shock absorber

A shock absorber and energy feeding technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of energy loss and dissipation, and solve the problem of unequal volume changes in the upper and lower chambers of the cylinder Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

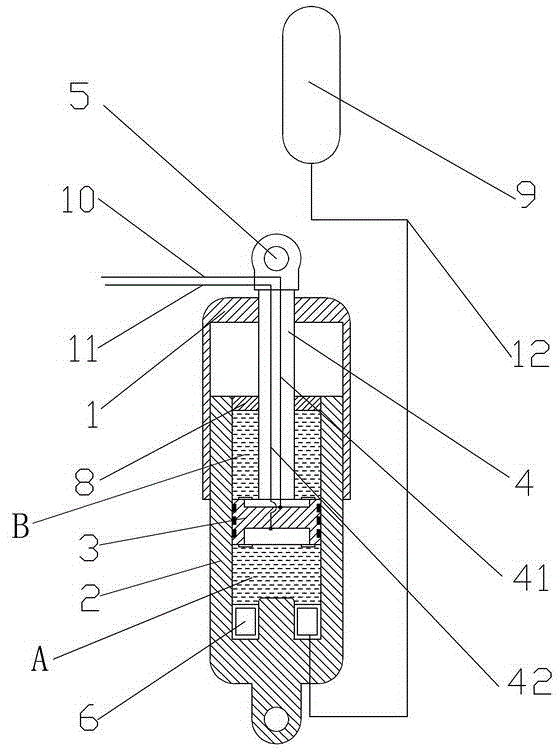

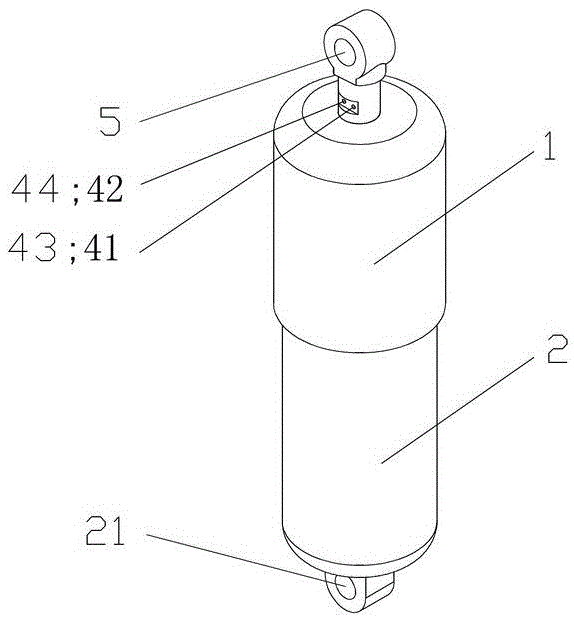

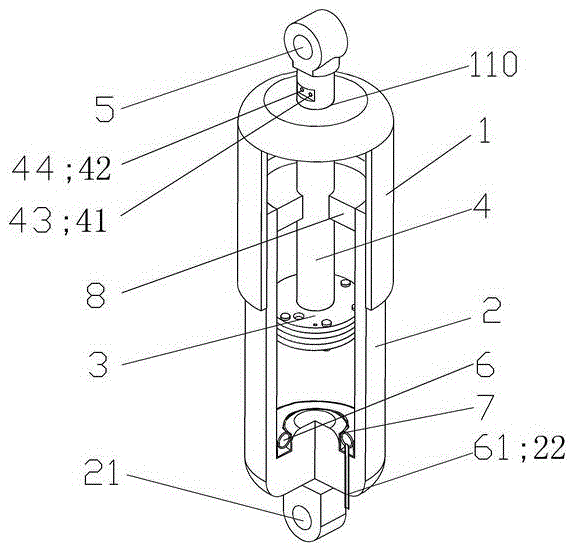

[0013] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention is composed of dust cover 1, cylinder barrel 2, combined piston 3, piston rod 4, single clevis 5, air bag 6, air bag protective cover 7, end cover 8, accumulator 9, the first high-pressure oil pipe 10. The second high-pressure oil pipe 11 and the high-pressure air pipe 12 are composed. The dust cover 1 is provided with a round hole 110; the cylinder 2 is provided with a single clevis 21 and a round hole 22; the combined piston 3 is It consists of a first disc 31, a second disc 32, a third disc 33, a fourth disc 34, two positioning pins 35, six bolts 37 and six nuts 36, the first disc 31 is provided with a A circular hole 311, a second circular hole 312, two third circular holes 313, a first positioning pin hole 314, a second positioning pin hole 315 and six first bolt holes 316; the second disc 32 is provided with a first E-shaped hole 321, the fourth round hole 322, the third position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com