Convenient rear brake assembly

A portable and assembly technology, which is applied in the field of vehicle brakes and rear brake assemblies, can solve the problems of affecting the overall performance of the brake, occupying a large space, and inconvenient installation, etc., and achieves the advantages of light weight, small space occupation and convenient assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

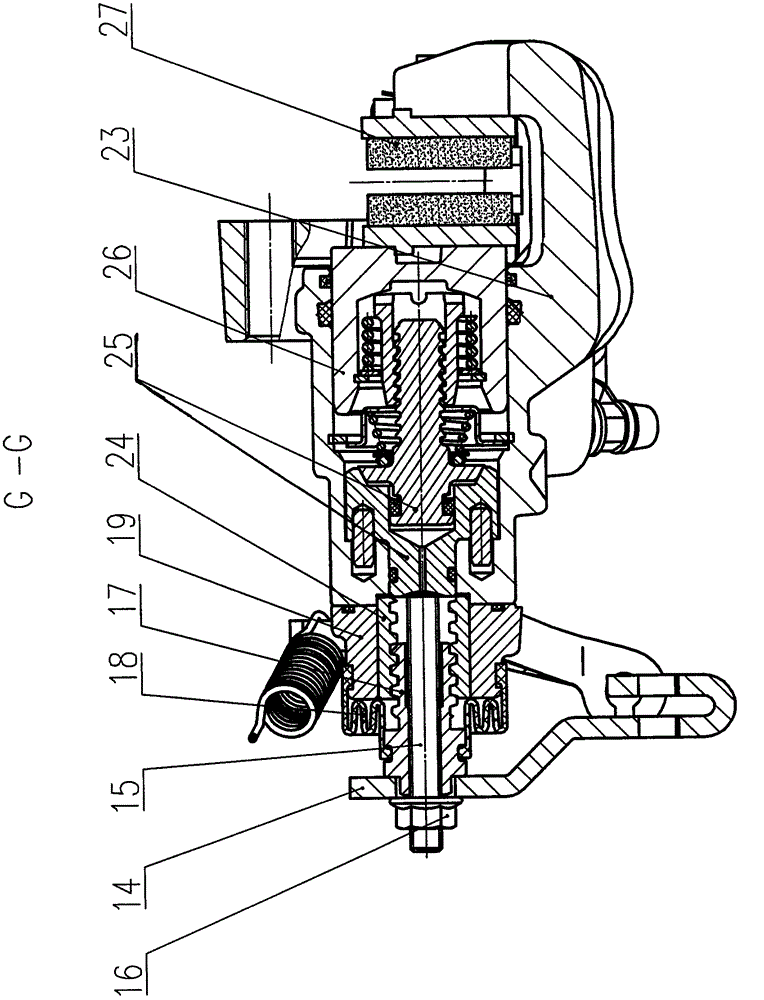

[0012] refer to Figure 1 to Figure 3 As can be seen, the present invention is applied to a portable rear brake assembly on a low-speed four-wheel electric vehicle, comprising a rear brake housing 23, a rear clamp assembly 25, a rear brake piston 26, a rear brake shoe 27 (and a shoe spring 7), Parking seat 19, parking rocking arm 14 (and extension spring 5), transmission nut 24 is housed in described parking seat 19, and transmission bolt 17 is sleeved in this transmission nut 24, is installed in described transmission bolt 17. There is an adjusting screw rod 15 connected with the rear clamp assembly 25 , and the other end of the adjusting screw rod 15 is connected with the parking rocker arm 14 .

[0013] Wherein, an adjusting nut 16 is installed on the adjusting screw rod 15 and at the junction of the adjusting screw rod 15 and the parking rocker arm 14 . A dust cover 18 is installed on the periphery of the drive nut 24 , the drive bolt 17 and the parking seat 19 . An air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com