Automatic oblique suspension water-blocking overflow impurity removal device

A technology for automatic sewage discharge and water blocking, applied in water conservancy projects, open water surface cleaning, construction, etc., can solve the problems of increased power generation cost, increased manufacturing cost, increased operating cost, etc., and achieves low manufacturing cost and maintenance cost, and structural design. Ingenious, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following embodiments of the present invention are given in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

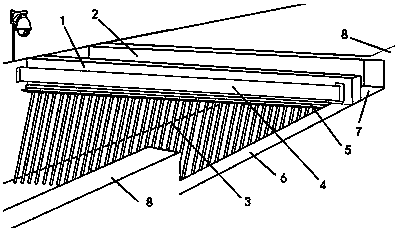

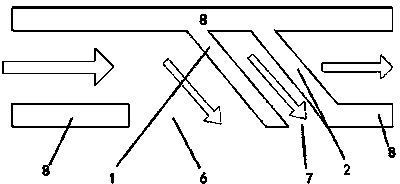

[0016] like figure 1 combine figure 2 As shown: the obliquely suspended automatic sewage discharge device described in this embodiment is to install two overflow obliquely suspended water blocking beams at the overflow / spill outlet of the canal 8 of the existing hydropower station, that is, the primary overflow obliquely suspended water blocking beams 1. The secondary overflow obliquely suspends the water blocking beam 2, both of which are fixed on the water channel 8 at an inclination angle of 60 degrees. Among them, one end of the primary overflow obliquely suspended water blocking beam 1 is fixed on the inner wall of one side of the water channel 8, and the other end is fixed on the overflow / spill outlet of the water channel 8 by tilting backward; the secondary overflow obliquely suspend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com