Fresh cocoon cooking device

A cooking device and a technology for fresh cocoons, which are applied in silk fiber production, textile and papermaking, mechanical processing, etc., can solve the problems of difficulty in controlling cocoon cooking time and temperature, and the quality of cocoon cooking cannot be guaranteed, and achieve high cooking efficiency. , The effect of less heat loss and clean operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

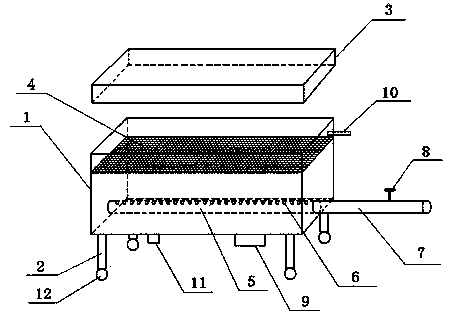

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] see figure 1 , fresh cocoon cooking device, including a rectangular body 1, the body 1 is installed on the bracket 2, the body 1 is provided with a cover 3, the body 1 is provided with a detachable net 4 in the horizontal direction, The lower part of the internal network 4 of the main body 1 is provided with a steam pipe 5, and the steam pipe 5 is provided with an upward steam hole 6, and the steam pipe 5 is connected with the steam inlet pipe 7 arranged outside the main body 1 , the steam inlet pipe 7 is provided with a control valve 8, the bottom surface of the body 1 is provided with a water outlet pipe 9 and a hot water inlet pipe 11; the side wall of the body 1 above the net 4 is provided with Overflow pipe 10; the steam pipe 5 is provided with a steam hole 6 every 10 centimeters, and the opening of the steam hole 6 is upward; the inner diameter of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com