Heat-soluble waterproof material

A raw material, hot melt technology, applied in the direction of wax paint, coating, etc., can solve the problem of floor tongue coloring and noise isolation effect needs to be further improved, and achieve the effect of remarkable waterproof effect, strong permeability and fast absorption speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

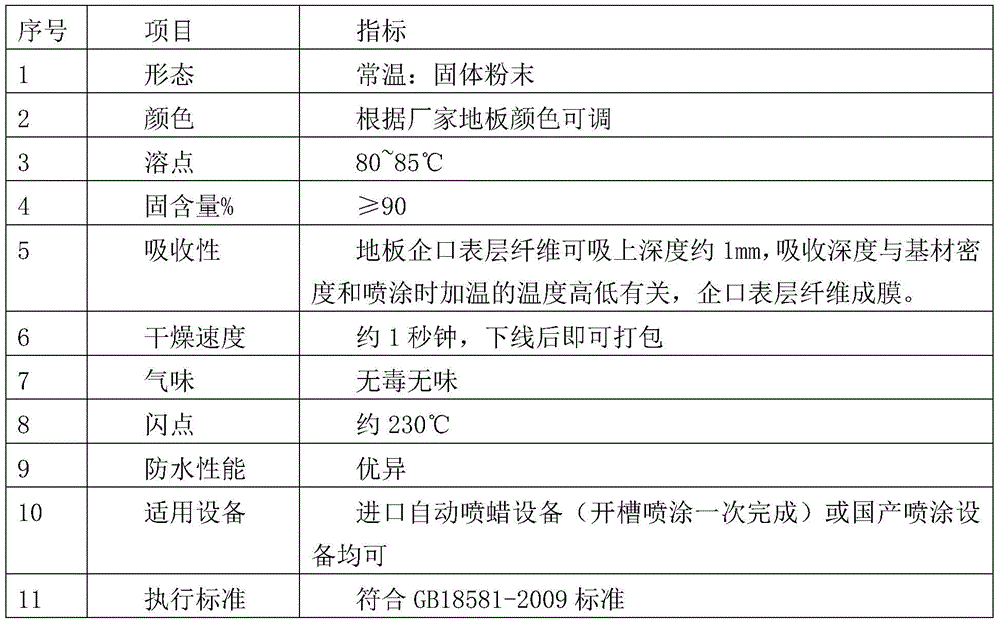

Image

Examples

Embodiment 1

[0012] Heat-soluble waterproof material, which consists of paraffin wax, dry oil (Japan Kanto Kasei FZ-610), fatty acid triglyceride mixture (Shenyang Xinchuan Chemical Co., Ltd., tung oil national standard), silicone oil defoamer, triethylhexyl phosphoric acid, poly Acrylamide, synthetic resin (polymer water-based acrylic resin, Guangzhou Star Chemical Material Co., Ltd.), polyimide resin (Qinyang Tianyi Chemical Co., Ltd. TY002), color enhancer (Hangzhou Lvdian Chemical Co., Ltd. LD4500), pigment (Germany Bayer pigment) raw materials; the mass percentage of each raw material is: paraffin wax 50%, dry oil 8%, fatty acid triglyceride mixture 5%, silicone oil defoamer 2%, triethylhexyl phosphoric acid 1.5% , Polyacrylamide 1.5%, synthetic resin 13%, polyimide resin 12%, color enhancer 3%, pigment 4%.

[0013] The pigments are red, yellow, black or blue pigments (existing pigments can be used).

[0014] The preparation of heat-soluble waterproof raw material comprises the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com