Method for longitudinally cutting side board of liquid crystal glass base plate

A liquid crystal glass substrate, longitudinal cutting technology, applied in the direction of glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problems of chopping, scratching, cutting glass substrates, etc., to eliminate pulling force and avoid scratching , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] specific implementation plan

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

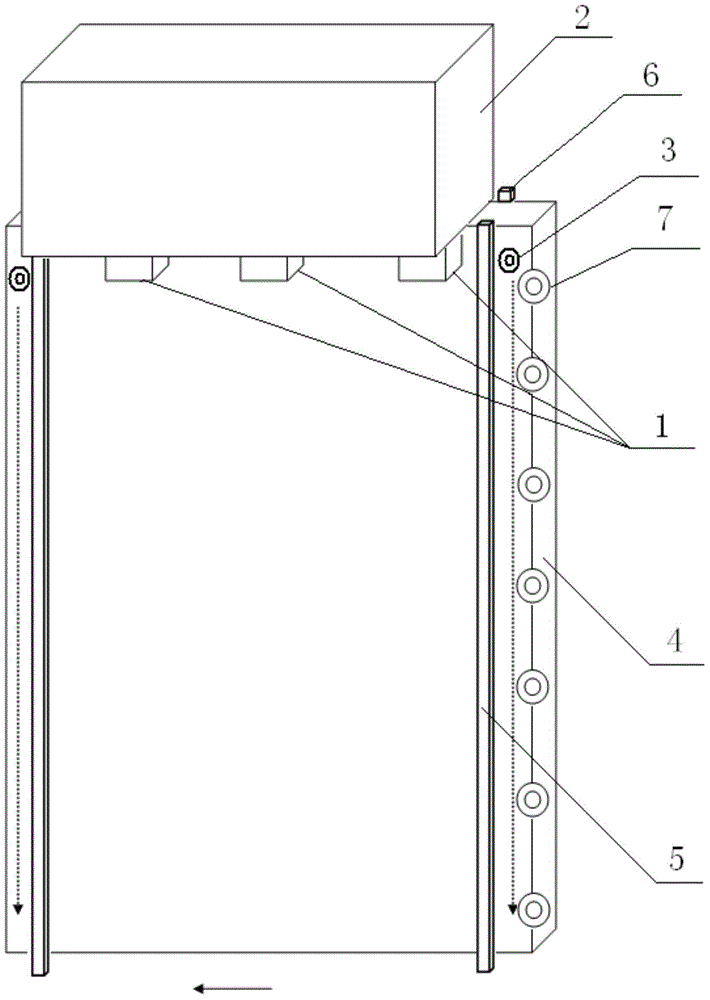

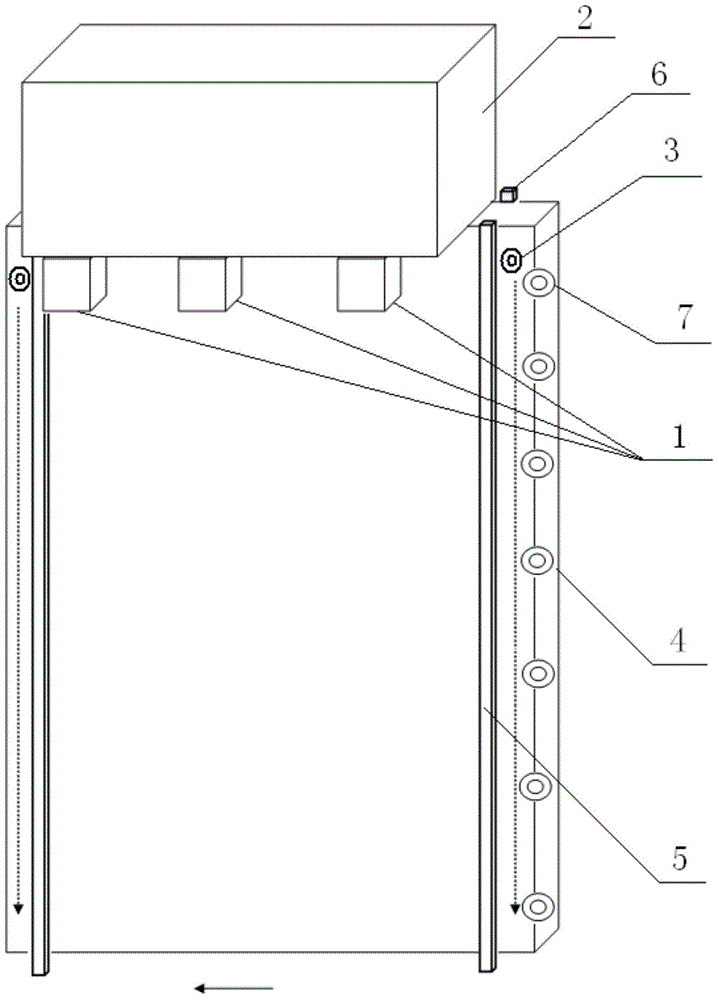

[0032] see figure 1 , in the production process of the liquid crystal glass substrate 4 in the past, the liquid crystal glass substrate 4 is cut horizontally after being formed, and the liquid crystal glass substrate 4 cut into pieces is hung on the tooling plate 2 of the semi-finished product conveyor belt by a robot, and the flow direction of the liquid crystal glass substrate 4 is as follows: As shown by the solid line arrow in the figure; the three jaws 1 on the tooling plate 2 clamp the liquid crystal glass substrate 4 for transportation, and after arriving at the semi-finished slitting station, the three jaws 1 on the tooling plate 2 clamp the liquid crystal glass substrate 4. Fix the liquid crystal glass substrate 4, the front and back of the slitting machine clamp the glass substrate by leaning against each other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com