Crane pull rope shaking motion conversion device and crane

A motion conversion and crane technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of increasing the weight of the trolley, high cost, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

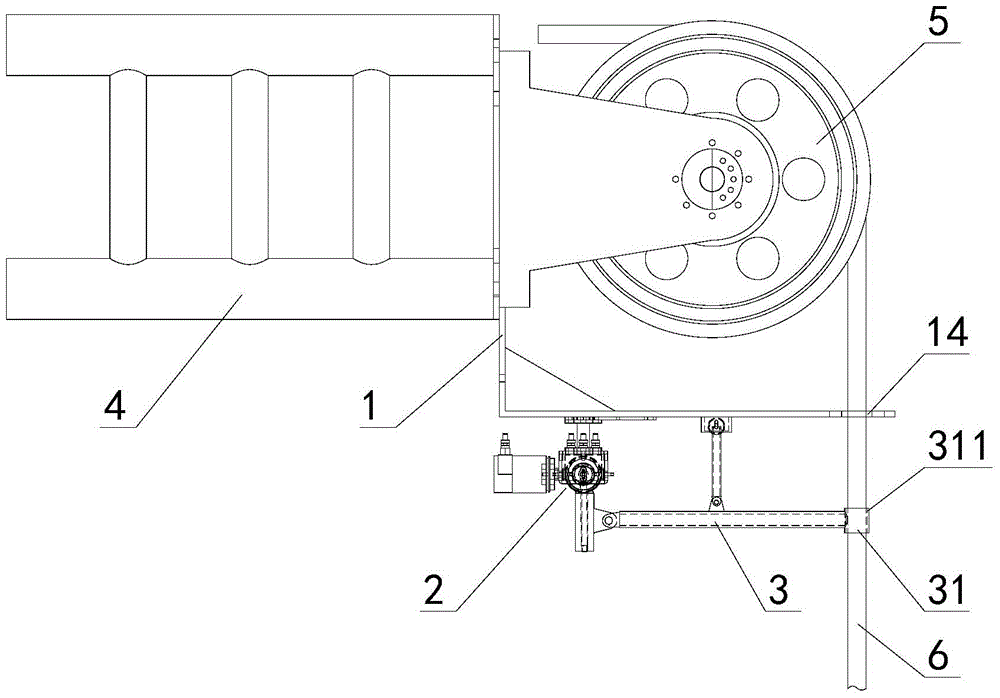

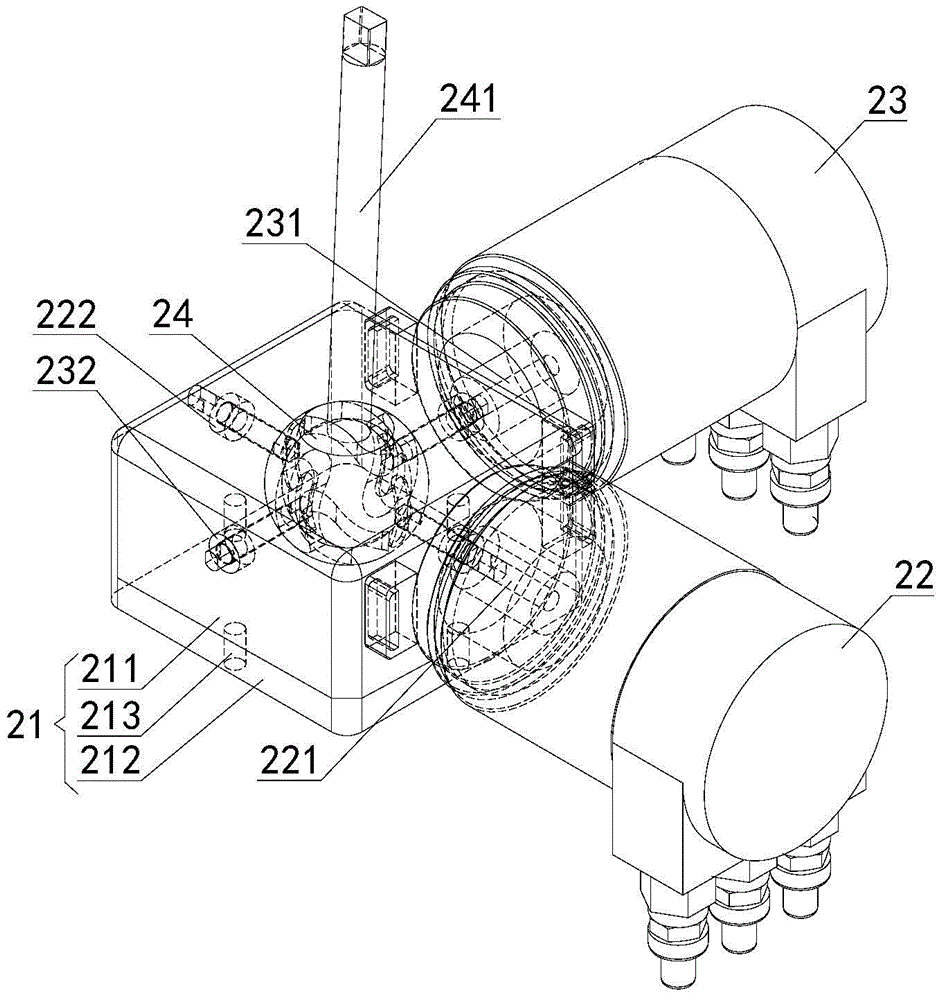

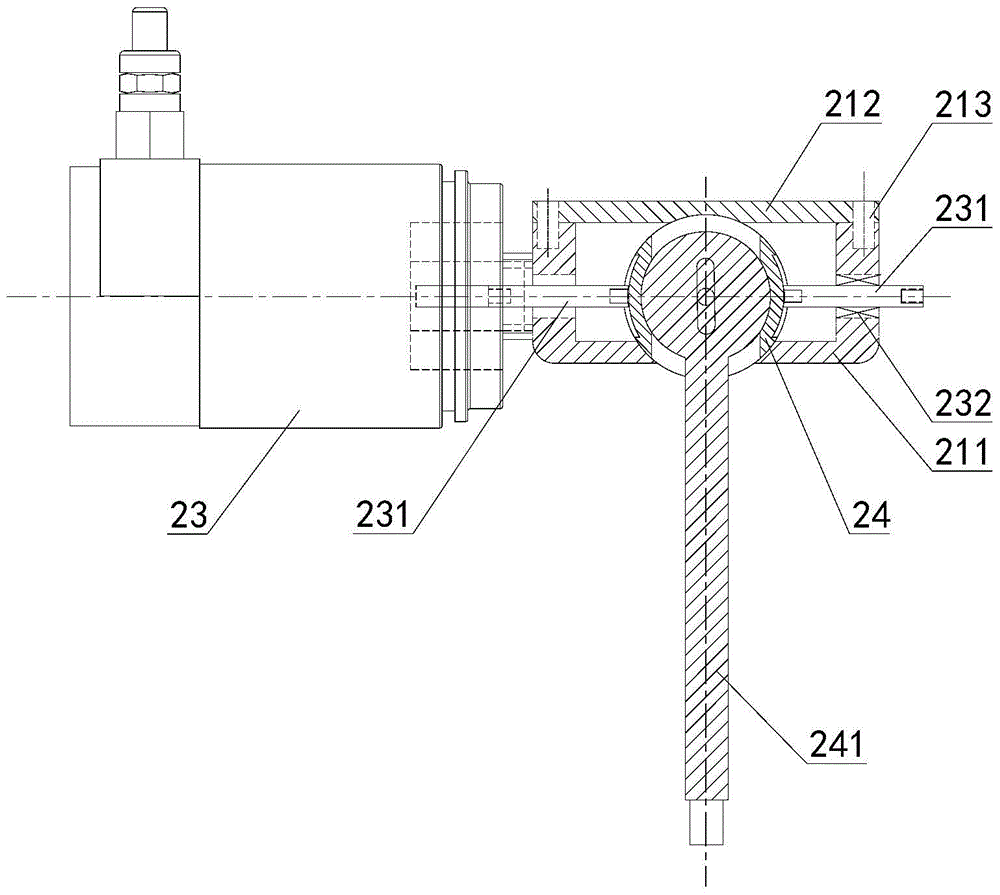

[0033] Such as figure 1 , figure 2 with image 3As shown, the crane pull rope shaking motion conversion device of this embodiment includes a mounting bracket 1, a detection component 2 and a sleeve connecting rod 3, the detection component 2 is fixed on the mounting bracket 1, the detection component 2 includes a casing 21, and the casing 21 is provided with There are the first motion state sensor 22 and the second motion state sensor 23 that are vertically arranged on the same horizontal plane. One end of the sleeve connecting rod 3 is provided with a thrust bearing 31 with a rope hole 311...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com