Fixing structure for bottle cap and bottle

A fixed structure and bottle technology, applied in the field of fixed structure of bottle caps and bottles, can solve the problems of loose lower cap and bottle neck, difficult to open the upper cap, liquid deterioration, etc. The effect of low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

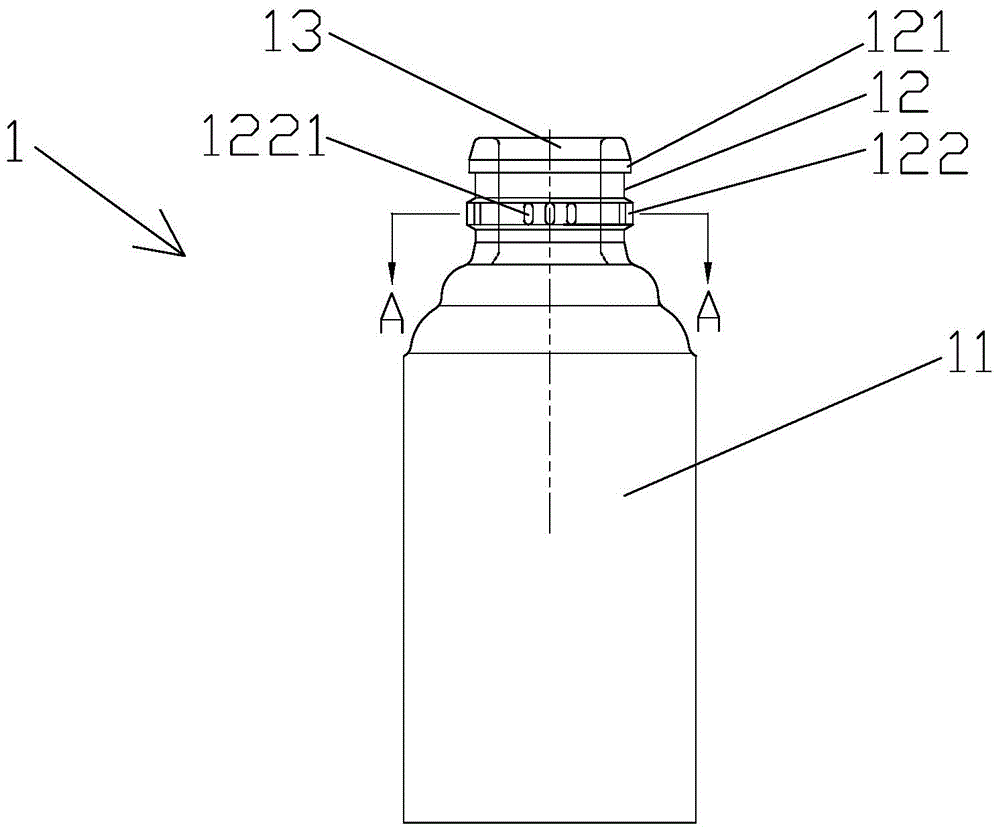

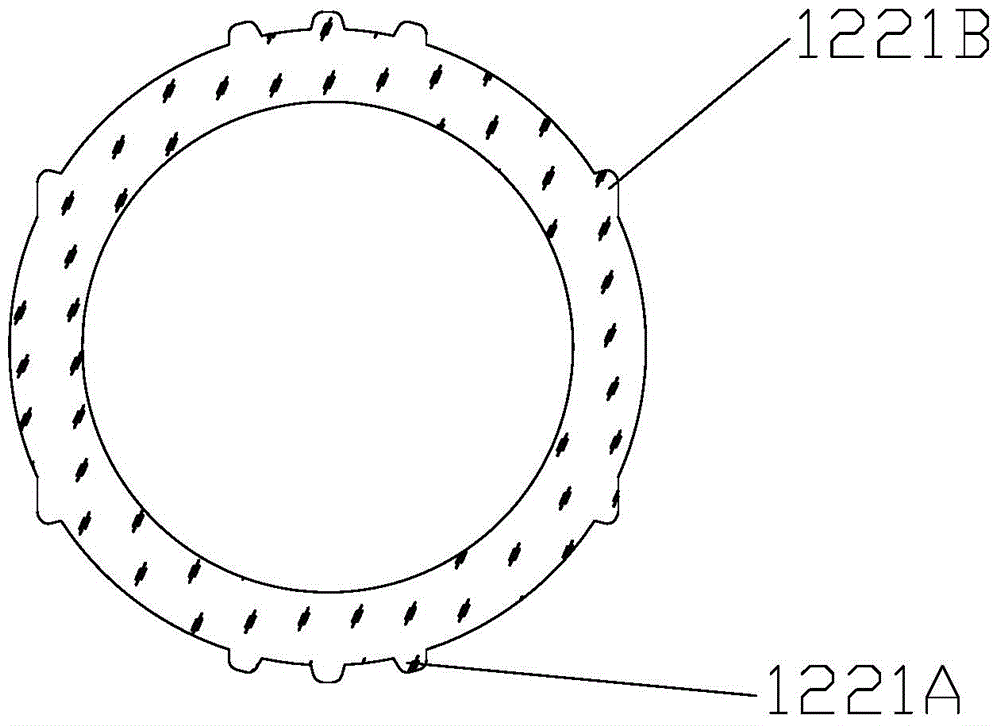

[0018] Embodiment, a kind of fixed structure of bottle cap and bottle, as Figure 1-2 As shown, the bottle 1 includes a bottle body 11, a bottleneck 12 and a bottleneck 13. On the peripheral wall of the bottleneck 12, an upper convex ring 121 and a lower convex ring 122 are arranged, and a plurality of convex rings 122 are arranged on the lower convex ring 122. Teeth 1221, the convex teeth 1221 include 6 arc-shaped convex teeth 1221A and 4 inclined convex teeth 1221B, furthermore, the arc-shaped convex teeth are divided into two groups and each group includes 3 arc-shaped convex teeth, inclined The convex teeth are divided into two groups and each group includes two inclined convex teeth. A group of inclined convex teeth is arranged between each two groups of arc-shaped convex teeth, and two adjacent two inclined convex teeth in each group in the opposite direction of inclination.

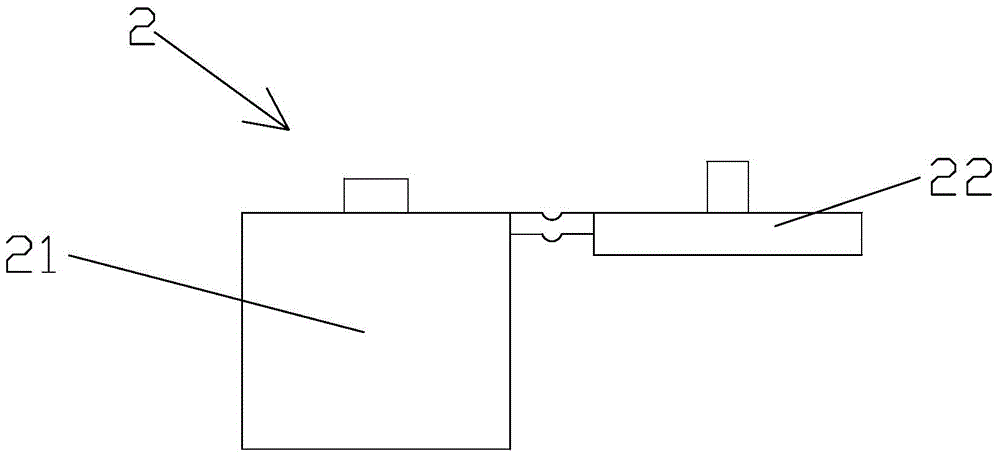

[0019] Such as image 3 As shown, the bottle 2 includes a lower cover 21 and an upper cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com