Transfer device for automobile sunroof product

A technology of a transfer device and a car sunroof, which is applied to trolleys, motor vehicles, multi-axle trolleys, etc., can solve problems such as waste of labor, increase manufacturing costs, and safety hazards such as scratches, and achieve the effect of convenient use and improved process efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

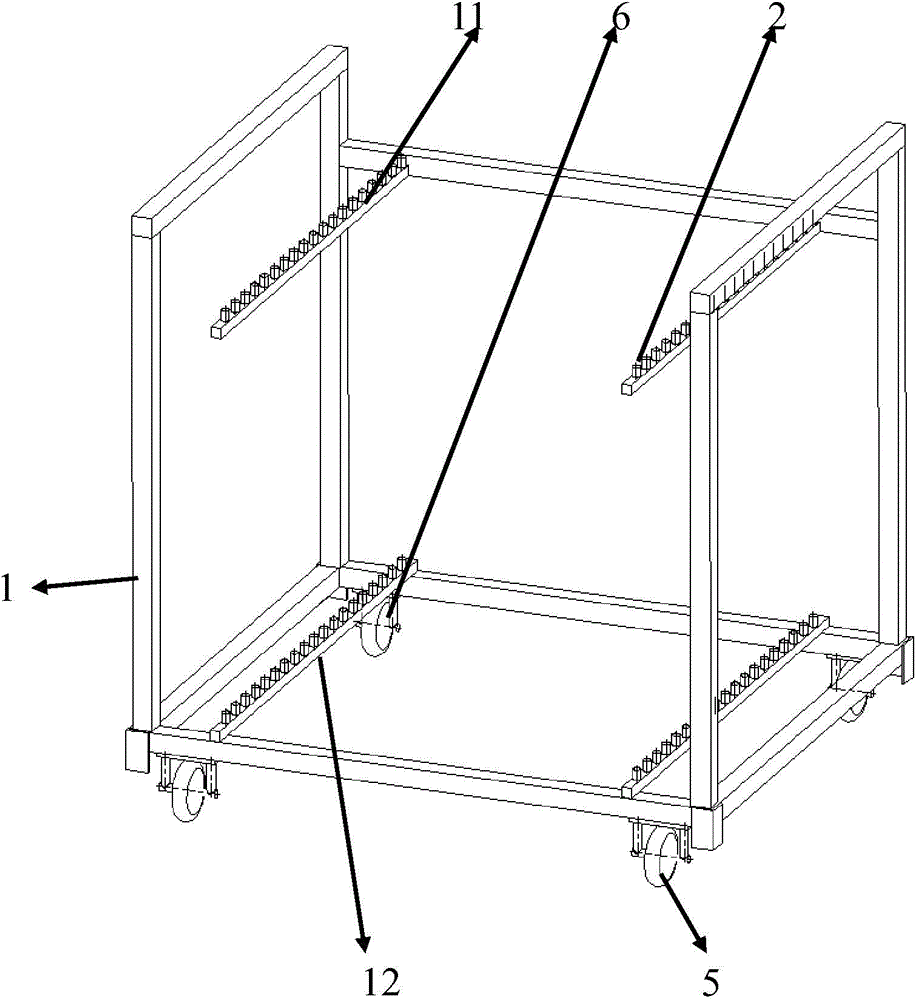

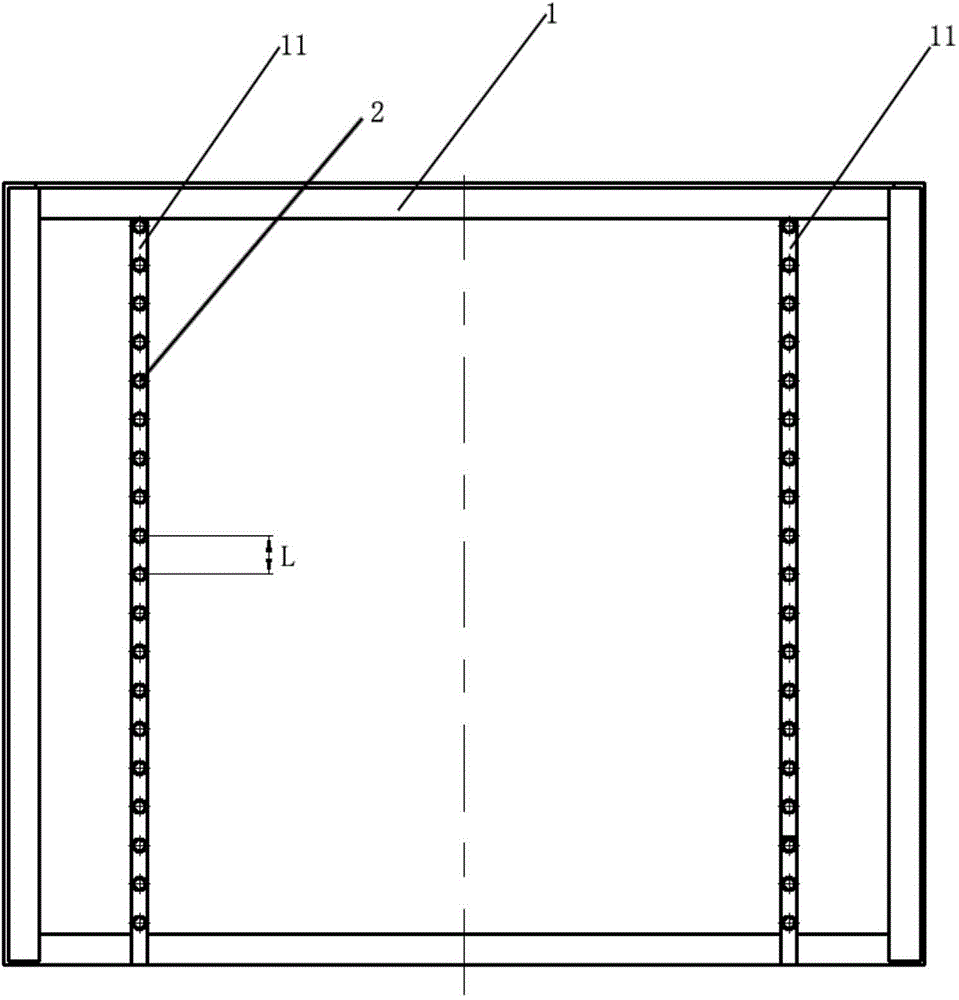

[0013] Such as figure 1 , 2 As shown, an automobile sunroof product transfer device includes a tooling base 1, two brackets 11 are fixed on the upper end of the tooling base 1, and two brackets 12 are fixed on the lower end of the tooling base 1, the first bracket 11 and the second bracket 12 A plurality of rubber limit posts 2 are arranged on the top, and the rubber limit posts 2 are arranged on the bracket through moving bolts, and the moving bolts are used to adjust the distance between the rubber limit posts 2 . Frock base 1 is pasted with skin all around.

[0014] The tooling base 1 is welded by square steel. The directional wheel 5 and the universal wheel 6 are installed on the bottom surface of the tooling base 1. The distance between the two brackets 11 and the two brackets 12 is 1-2mm longer than the length of the product. , the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com