Fixed shaft compass

A compass and fixed-axis technology, applied in the field of fixed-axis compasses, can solve the problems of enlarged holes, unclear circles, damage, etc., and achieve the effect of uniform and clear lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described in detail below.

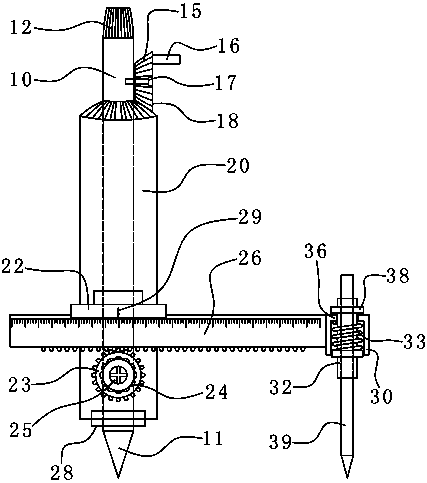

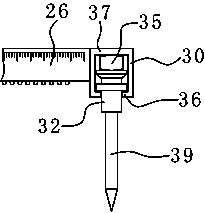

[0019] refer to figure 1 , figure 2 As shown, the present invention is a fixed axis compass, which includes a fixed vertical shaft 10, a rotating sleeve 20 rotatably sleeved on the fixed vertical shaft 10, a sleeve rail 22 fixedly connected to the side of the rotating sleeve 20, and sleeved on the The sleeve rail 22 is a cross bar that can slide laterally, and a pen holder 32 that can be elastically connected to the end of the cross bar longitudinally. Set the fixed vertical shaft 10 to prevent the needle point at the lower end of the vertical shaft from stabbing the paper surface during rotation, and protect the paper surface. The rotating sleeve 20 connects the sleeve rail 22 and the cross bar so that the cross bar can move laterally and choose a circle or an arc. radius, rotate the rotating sleeve 20 to draw circles or arcs on the paper, and the pen for drawing circles or arcs is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com