Tencel fiber and cotton fiber composite material

A technology of Tencel fiber and composite material, applied in the field of fabrics, can solve the problems of poor resilience, degumming, weft cracking, etc., and achieve the effects of improving durability, preventing strong rigidity and improving bonding firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

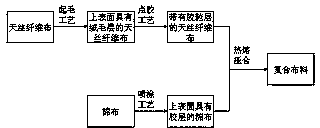

Method used

Image

Examples

Embodiment 1

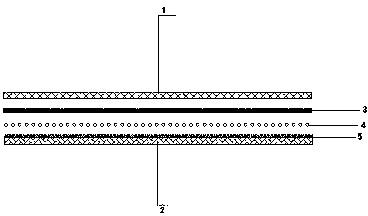

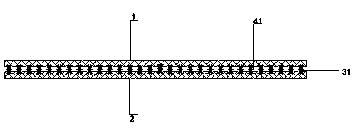

[0039] Such as figure 1 Shown:

[0040] (1) Use the raising machine produced by Haiwei Machinery Rubber Roller Co., Ltd. to raise the Tencel fiber cloth layer, so that the upper surface of the Tencel fiber cloth layer forms a fluff layer with a uniform density, forming a thickness of 0.5~2mm and a density of 10~ 100 fluff layers / mm.

[0041] (2) Use the dispensing machine produced by Dongguan Hongcheng Machinery Co., Ltd. to pass the Tencel fiber cloth layer that has completed the above step (1) at a constant speed of 0.5m / s, so that the upper layer of the fiber cloth is evenly covered. Polyether sulfone resin melt glue point, and then enter the heating chamber at a temperature of 185 ℃ to melt the solid rubber particles, after passing through the heating chamber, the rubber particles are cooled in the air to form hemispherical glue points, so that the upper surface of the tencel fiber cloth layer is formed Hemispherical polyethersulfone resin melt glue points evenly arra...

Embodiment 2

[0045] Such as figure 1 Shown:

[0046] (1) Use the raising machine produced by Haiwei Machinery Rubber Roller Co., Ltd. to raise the Tencel fiber cloth layer, so that the upper surface of the Tencel fiber cloth layer forms a fluff layer with uniform density, forming a thickness of 0.5~0.9mm and a density of 10 ~25 fluff layers / mm.

[0047] (2) Use the dispensing machine produced by Dongguan Hongcheng Machinery Co., Ltd. to pass the Tencel fiber cloth layer that has completed the above step (1) at a constant speed of 0.5m / s, so that the upper layer of the fiber cloth is evenly covered. Polyether sulfone resin melt glue point, and then enter the heating chamber at a temperature of 185 ℃ to melt the solid rubber particles, after passing through the heating chamber, the rubber particles are cooled in the air to form hemispherical glue points, so that the upper surface of the tencel fiber cloth layer is formed Hemispherical polyethersulfone resin melt glue points evenly ar...

Embodiment 3

[0051] Such as figure 1 Shown:

[0052] (1) Use the raising machine produced by Haiwei Machinery Rubber Roller Co., Ltd. to raise the Tencel fiber cloth layer, so that the upper surface of the Tencel fiber cloth layer forms a fluff layer with uniform density, forming a thickness of 0.5~0.9mm and a density of 10 ~25 fluff layers / mm.

[0053] (2) Use the dispensing machine produced by Dongguan Hongcheng Machinery Co., Ltd. to pass the Tencel fiber cloth layer that has completed the above step (1) at a constant speed of 0.5m / s, so that the upper layer of the fiber cloth is evenly covered. Nylon melt glue points, and then enter the heating chamber to melt the solid rubber particles at a temperature of 185 ° C. After passing through the heating chamber, the rubber particles are cooled in the air to form hemispherical glue points, so that the upper surface of the tencel fiber cloth layer forms adjacent glue. Hemispherical nylon melt glue dots arranged evenly with a dot dista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com