Tabletting machine capable of preventing fragmentation

An anti-fragmentation and tablet press technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of improper particle compression, uneven pressure, and fragile tablets. The effect of reducing agent fragmentation, reducing dust and prolonging tableting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

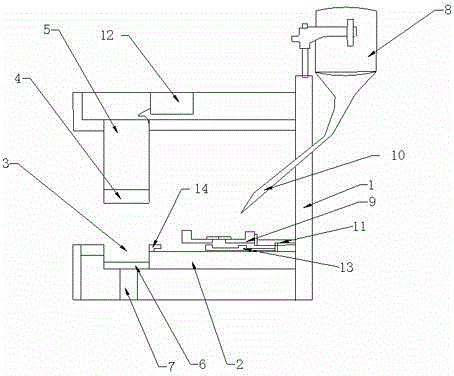

[0031] like figure 1 As shown, the anti-fragmentation tablet press includes a frame 1, on which an upper die 4, a middle die 2 and a lower die 6 are arranged from top to bottom, and the upper die 4 is connected to drive the upper die 4 to move up and down The upper drive mechanism 5, the lower punch 6 is connected with the lower drive mechanism 7 that drives the lower punch 6 to move up and down, the middle die 2 is provided with a die hole 3, the die head of the upper die 4 and the die head of the lower die 6 are all connected to the die hole 3, and the axes of the upper die 4, the lower die 6 and the die hole 3 are coincident; the right side of the frame 1 is provided with a feeding hopper 8, and the upper part of the frame 1 is also provided with an upper drive mechanism 5 to control the upper Time relay 12 for the dwell time when the die 4 is pressed down onto the tablet.

[0032] When the single-punch tablet machine compresses the tablet, the upper surface of the tablet ...

Embodiment 2

[0039] like figure 1 As shown, similar to embodiment 1, the difference is:

[0040] Also be provided with recovery tank 13 between charging box 9 and middle mold 2, recovery tank 13 comprises tank body and connecting rod, the central axis of the tank body of recovery tank 13 coincides with the central axis of charging hole, the bottom surface of tank body and middle mold The upper end faces of 2 are located on the same horizontal plane. The area of the tank body of the recovery tank 13 should be larger than that of the feeding hole. This is because there is a gap between the feeding hole and the feeding box 9, and the powder is easy to leak from the gap, resulting in waste of raw materials. The setting of the recovery tank 13 can prevent powder leakage. , to reduce waste.

[0041] The connecting rod of the recovery tank 13 is connected with the box pushing mechanism 11, and the middle mold 2 is positioned on the right side of the die hole 3 and is also provided with a limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com