Bearing dismantling device

A bearing dismounting device and bearing technology, which is applied to hand-held tools, manufacturing tools, etc., can solve problems such as waste of resources, abnormal operation of bearings, and large vibration, so as to reduce repairs or replacements, shorten production cycles, and ensure safe use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

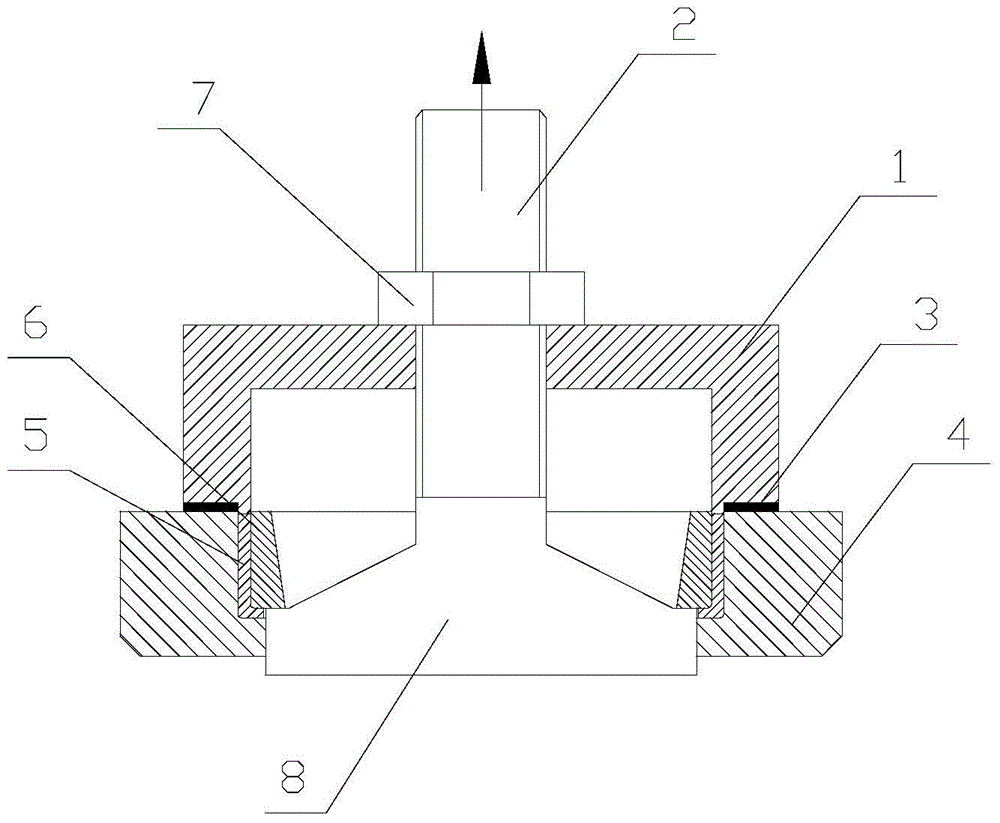

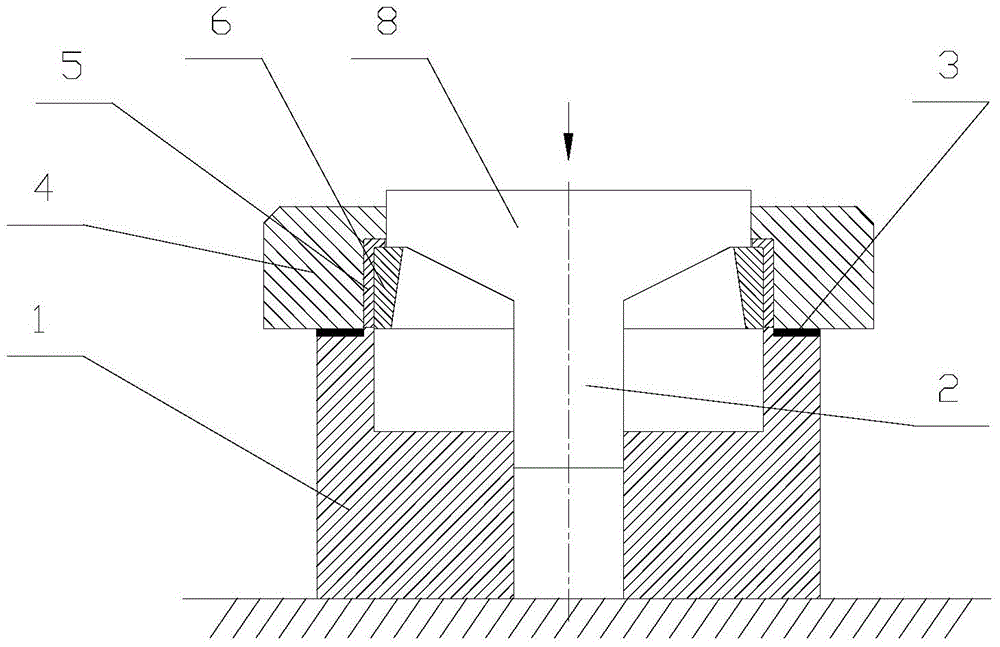

[0008] As shown in the figure, the bearing removal device includes a pull rod 2, a pressure ring 1, and an adjustment pad 3. The pressure ring 1 is fixed in the direction in which the bearing outer ring 6 is disassembled, and is in the shape of a round cup. The end face of the part 4 of the bush is matched, and the end face of the pressure ring 1 is also provided with a protruding step, and the step is matched with the end face of the bearing bush 5. greater than the width of the bearing outer ring 6; the tie rod 2 and the bottom of the pressure ring 1 have a gap fit, and one end is designed with a disc 8, the end face of the disc 8 can be in contact with the end face of the bearing outer ring 6, and can follow the pull rod 2 Move in the direction of disassembly; the pull rod 2 passes through the bottom of the pressure ring 1, and the nut 7 is installed through the thread. As another method of the present invention, the bottom of the pressure ring 1 is placed on a fixed plane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com