Vacuum loading device

A vacuum and carrier technology, applied in the field of tooling and fixtures, can solve the problems of surface processing dead points, small processing space of processing equipment, affecting assembly, etc., to achieve convenient and rapid installation and timely removal, ensure high precision machining requirements, avoid The effect of compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

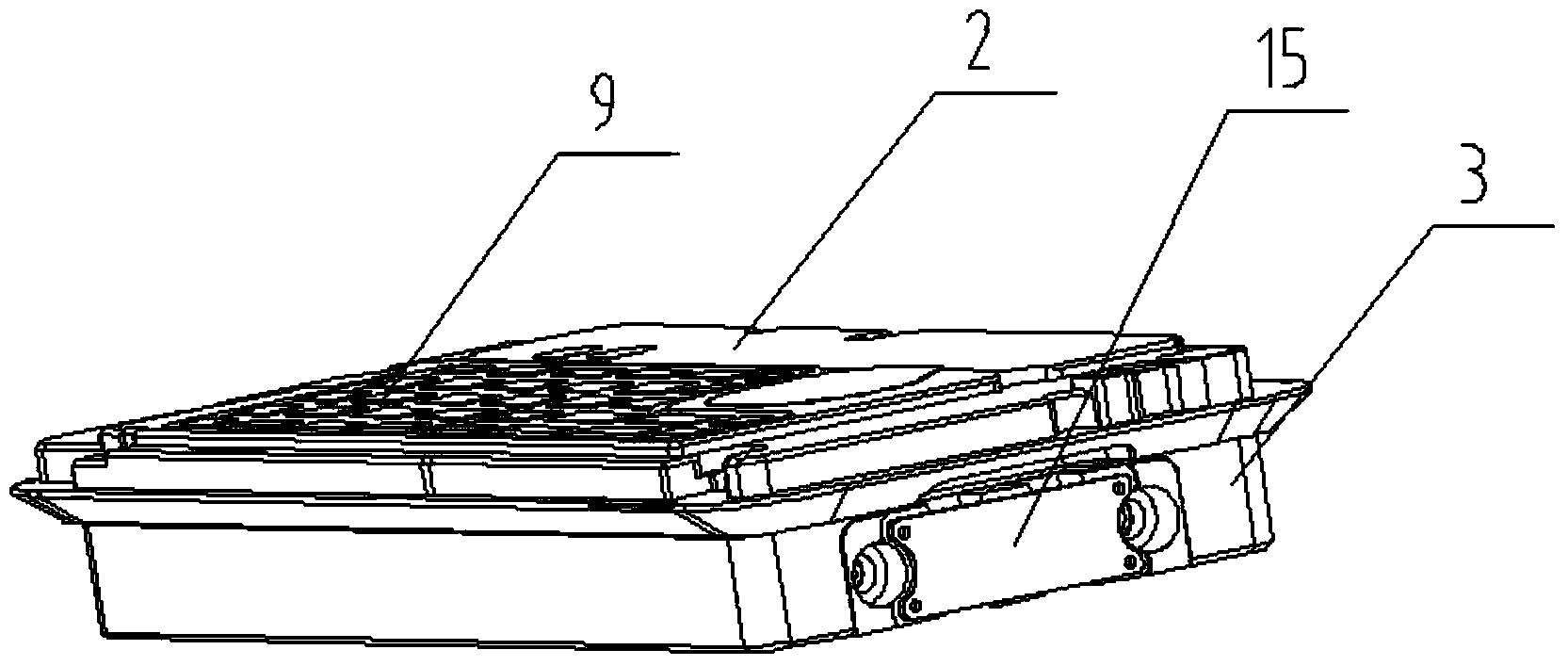

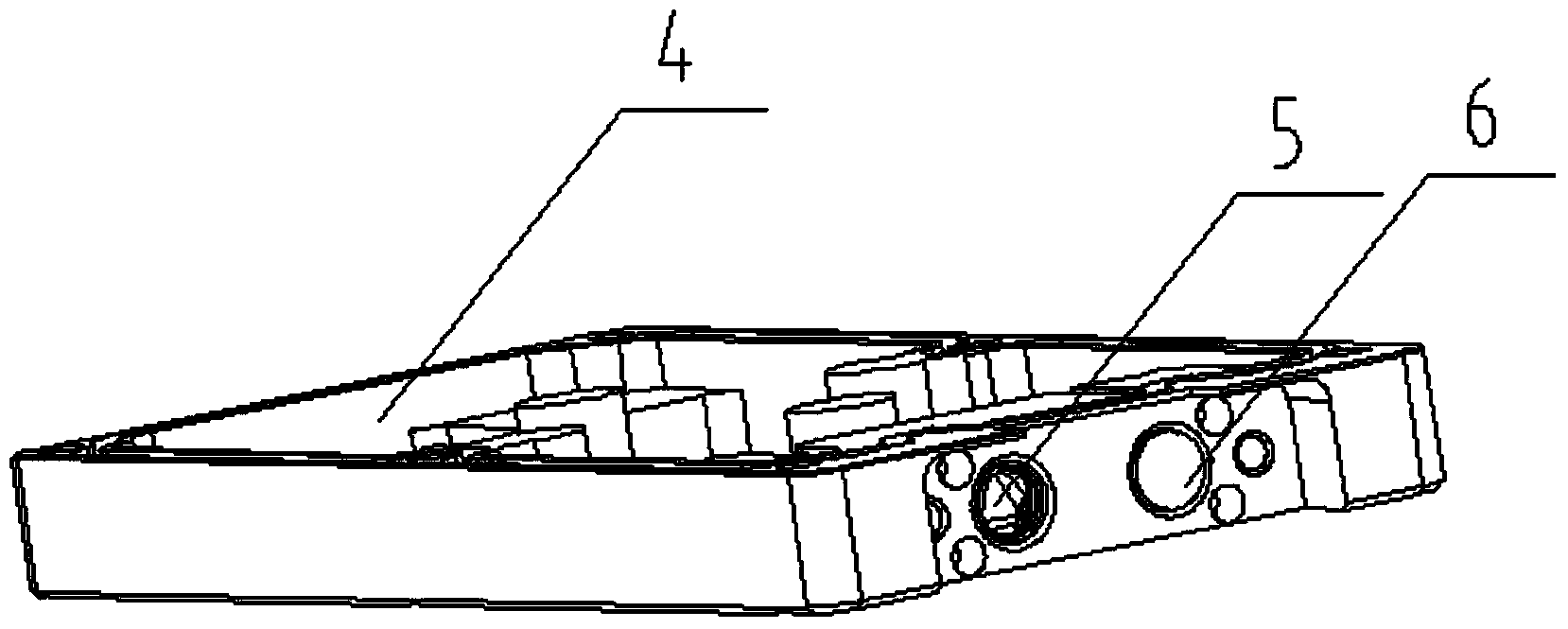

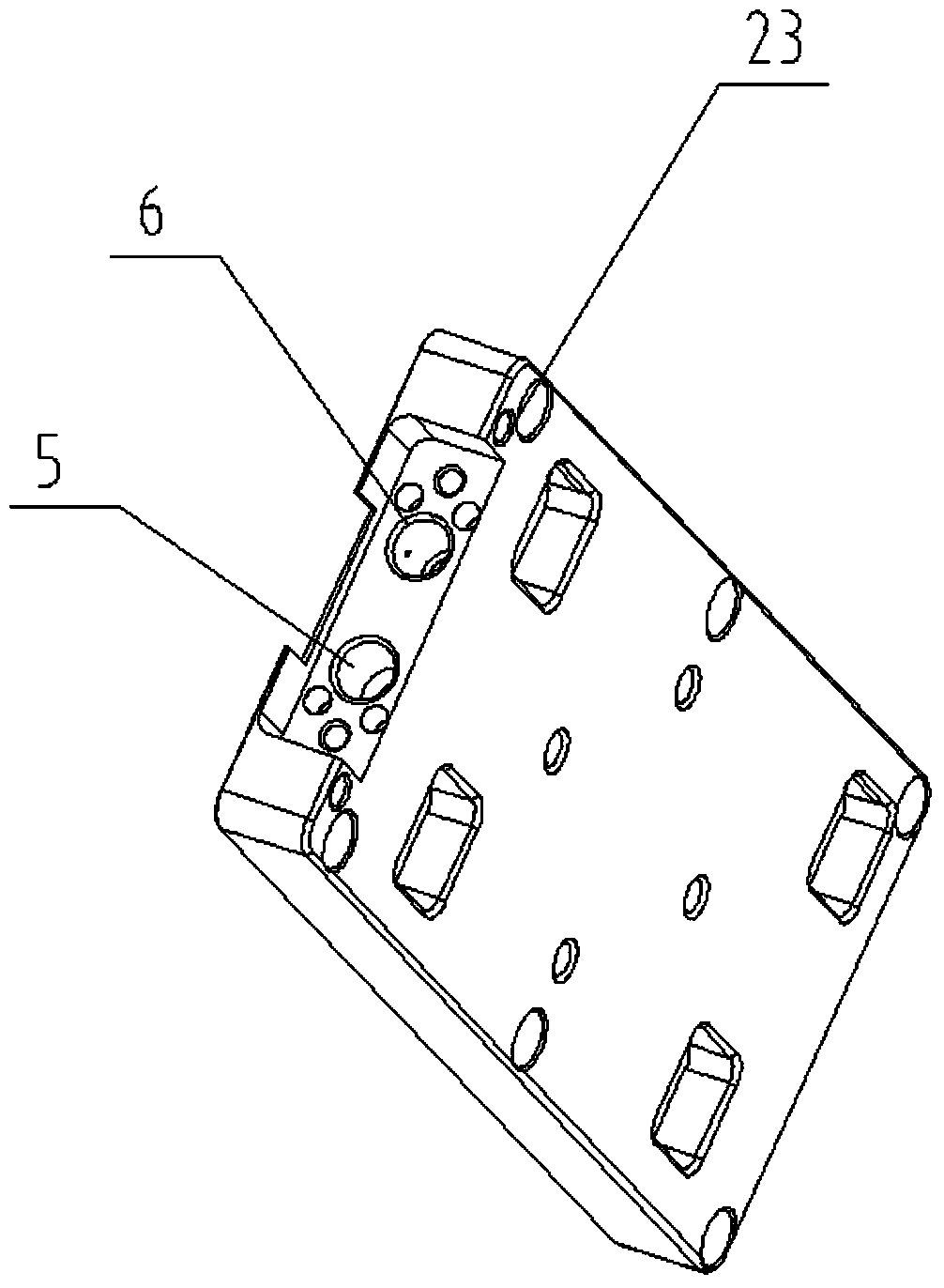

[0027] Embodiment: A vacuum carrier includes a carrier body 1. The carrier body 1 includes a top cover 2 and a main board 3. The top cover 2 can be disassembled and sealed to cover one side of the main board 3. A gap is formed between the top cover 2 and the main board 3. Sealed vacuum holding cavity 4, a vacuum loading port 5 and a vacuum releasing port 6 are respectively formed on the side wall of the vacuum holding cavity 4, and a vacuum charging port 5 is provided with a hole only for gas to flow out of the vacuum holding cavity 4 One-way valve 7, a sealing plug 8 capable of sealing the vacuum release port 6 is provided in the vacuum release port 6, the side of the top cover 2 facing away from the main board 3 is the outer side, the side facing the main board 3 is the inner side, and the top cover 2 is outside A number of concave cavities 9 matching the suction products are formed on the surface, a ring of sealing strips is provided on the edge of the concave cavities 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com