Fixture for welding the front floor of the car and the front seat mounting beam

A technology for the front floor and front seats of a car, which is applied to welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve the problems of complex rotating arm mechanism, poor stability, and potential safety hazards of accidentally injuring operators. Achieve the effect of improving operating comfort and work efficiency, ensuring accuracy and stability, and reducing hidden dangers of operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

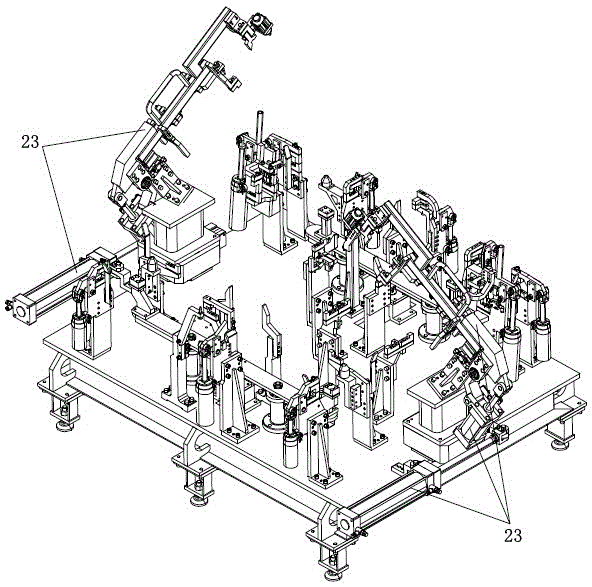

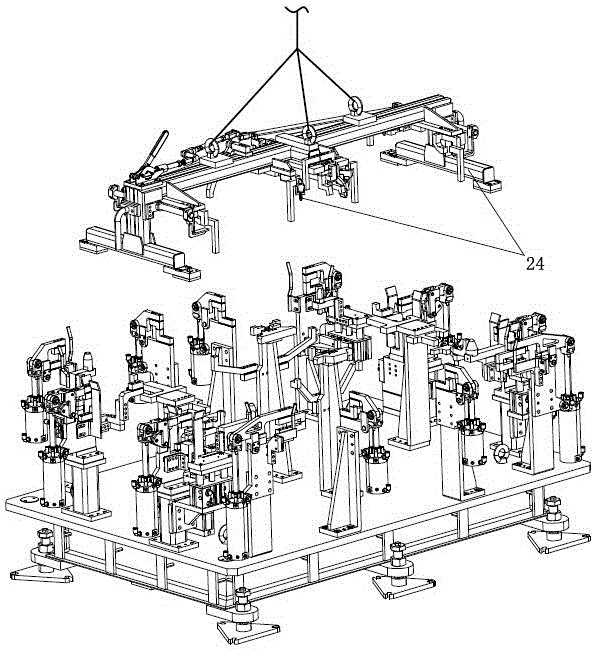

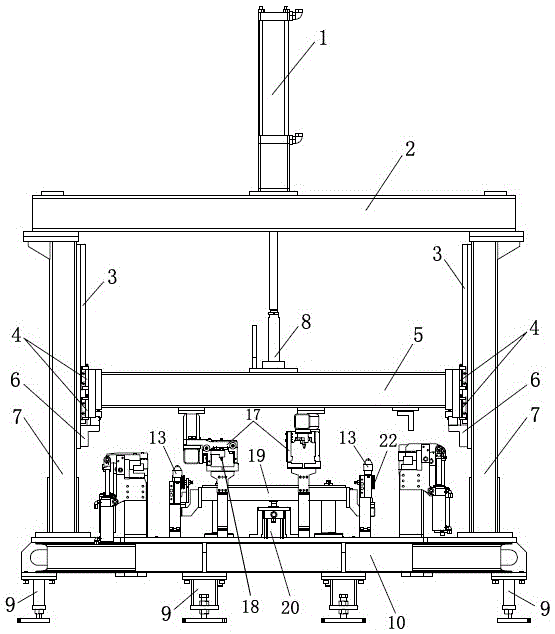

[0027] Such as Figure 3~Figure 5 As shown, the clamp used for welding the front floor of the automobile and the front seat installation beam according to the present invention includes a clamp base 10, a front floor positioning clamping device and a front seat installation beam positioning clamp located on the clamp base. device.

[0028] The front row seat mounting crossbeam positioning and clamping device includes four uprights 7, which are equally divided into two groups, one group is fixed on the left middle part of the clamp base, and the other group is fixed on the right side middle part of the clamp base. The tops of the two columns are fixed together by a connecting plate. It also includes a fixed beam 2 connecting the top of the column. The fixed beams are also two, parallel and juxtaposed, connected to the top of the column through the connecting plate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com