Wire cutting machine capable of fast clamping

A wire cutting machine and clamping technology, which is applied in the direction of accessory devices, electric processing equipment, metal processing equipment, etc., can solve the problems of cumbersome operation, affecting efficiency, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

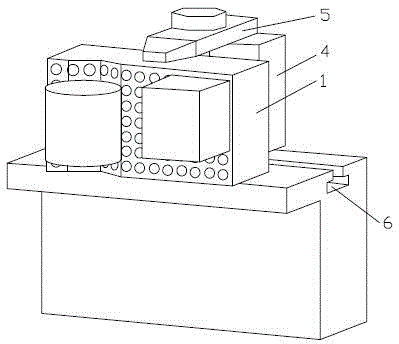

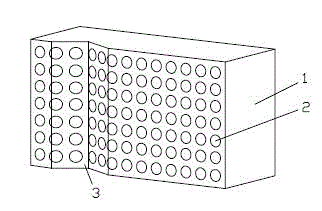

[0012] figure 1 , figure 2 Shown is the wire cutting machine for fast clamping provided by the present invention, including a frame, a workbench is arranged on the frame, at least one clamp is arranged on the workbench, the clamp includes a spacer 4 and a pressure plate 5, and the pressure plate 5 is provided with strips There are T-shaped slots 6 on the workbench, and nuts are arranged in the T-shaped slots 6. The fixture also includes a suction cup 1. The suction cup 1 is a cuboid. One surface of the suction cup 1 is an adsorption surface, and there are multiple rows of round holes on the adsorption surface. 2. The round hole 2 is filled with magnetic substances; the suction surface of the suction cup 1 is provided with a V-shaped groove 3; the two ends of the pressure plate 5 are respectively pressed on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com