Die press fitting equipment

A mold and equipment technology, applied in the field of mold pressing equipment, can solve the problems of complex shape, complicated operation and high price, and achieve the effect of durable equipment, simple operation and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

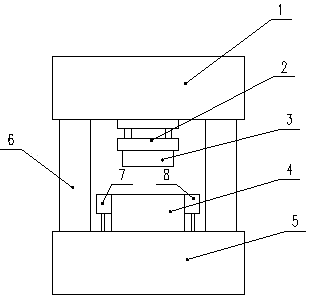

[0016] As shown in the accompanying drawings: a mold pressing equipment, which includes an upper connection support 1, an upper mold connection block 2, an upper mold movable block 3, a lower base 4, a workbench 5, a cylinder column 6, a left feeding bracket 7, Right discharge support 8.

[0017] The upper connecting support 1 is made of cast steel, an upper die connecting block connection device is arranged in the center of the upper connecting support, and cylinder column connecting holes are arranged around the upper connecting support.

[0018] The movable block 3 of the upper die is a square connection block made of steel plates, and a U-shaped groove is arranged under the movable block of the upper die.

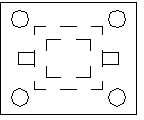

[0019] Described lower base 4 is made by 45# steel plate, is provided with mold installation connection hole in the center of lower base, is provided with workbench installation connection hole around the lower base.

[0020] The workbench 5 is made of cast steel, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com