Chilli hull and seed separator

A technology of separator and chili seeds, which is applied in solid separation, wet separation, filtration and sieving, etc., can solve the problems of easily damaged chili seeds, low production efficiency, and affecting seed quality, and achieves improved production efficiency, simple structure, and design ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the present invention will be further explained through the embodiments and the accompanying drawings:

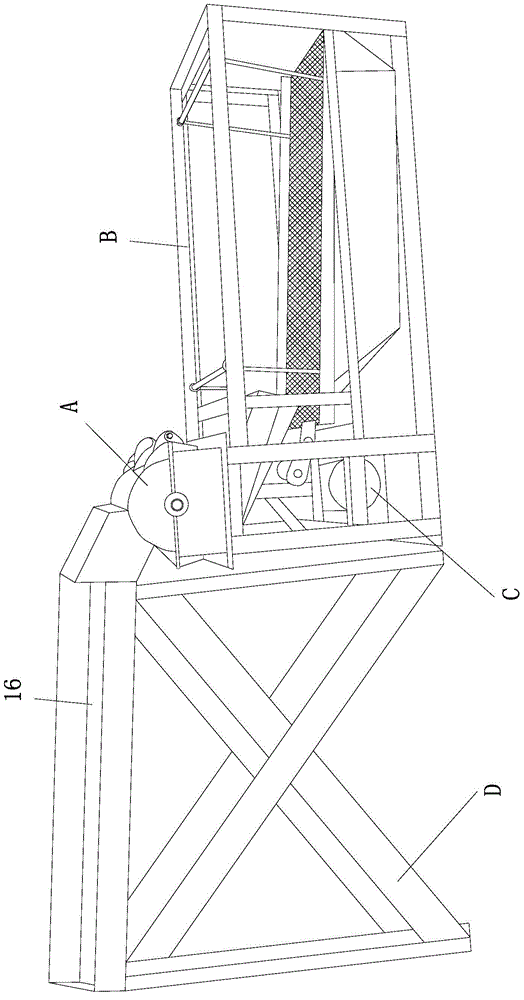

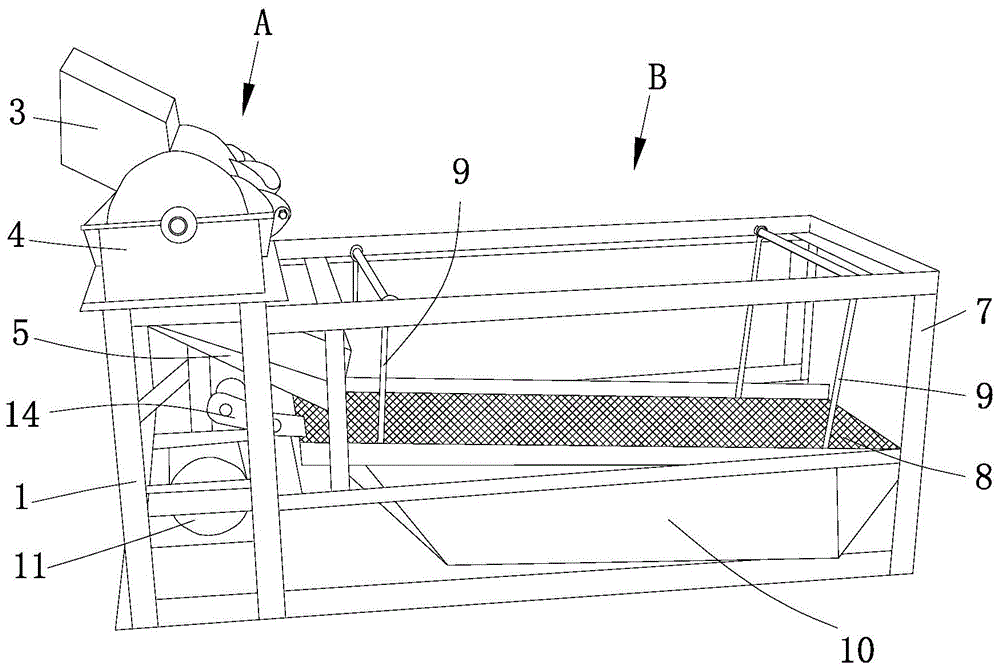

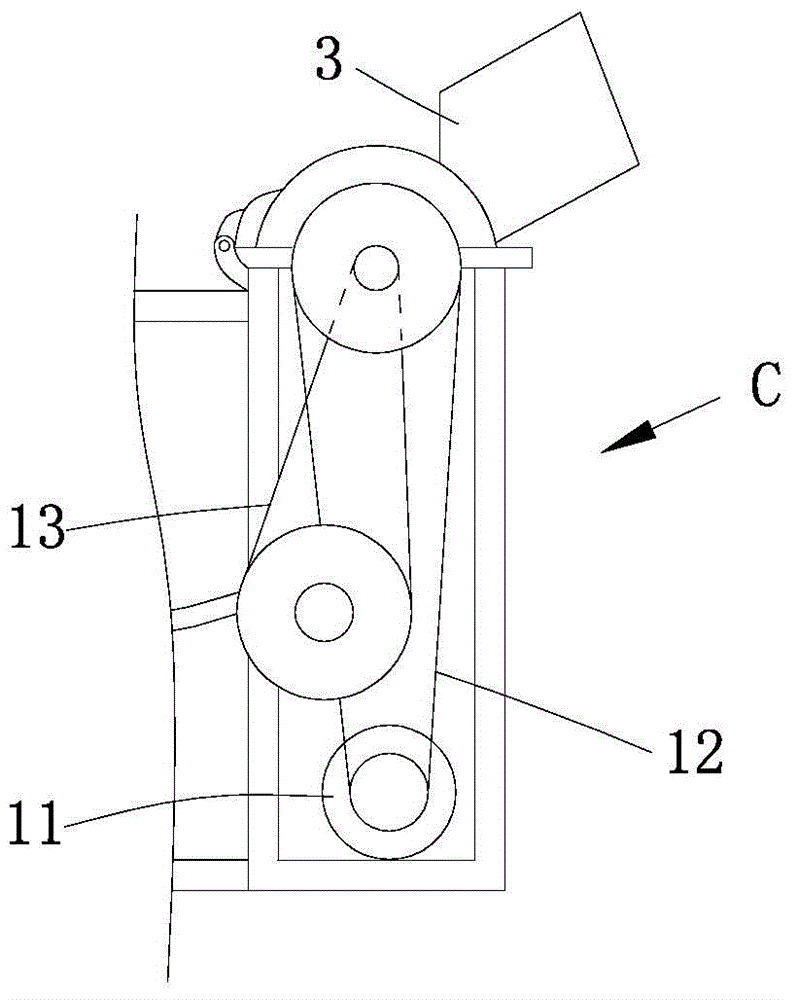

[0022] Combine figure 1 —— Image 6 As shown, a pepper seed husk separator is mainly composed of a crushing mechanism A, a distributing mechanism B, a driving mechanism C, and a feeding mechanism D. Among them, the feeding mechanism D, the crushing mechanism A and the distributing mechanism B are arranged in sequence.

[0023] The crushing mechanism A is mainly composed of the first support frame 1, the mixing and crushing wheel 2, the feeding hopper 3, the crushing bin 4, the discharging hopper 5 and the crushing grid 6. The feeding hopper 3, the crushing bin 4, and the discharging hopper 5 are fixedly connected in sequence and then installed on the first support frame 1. The first support frame 1 is a bracket structure welded by steel plates. The feeding hopper 3 is located at the front and upper part of the crushing bin 4, the discharging hopper 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com