Straw cutting, throwing and returning machine for combined harvester and mounting method of straw cutting, throwing and returning machine

A combine harvester and straw technology, which is applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve problems such as affecting life and traffic safety, reducing effective utilization, and wasting resources and the environment, so as to reduce the number of operations and solve problems such as The problem of straw burning and the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

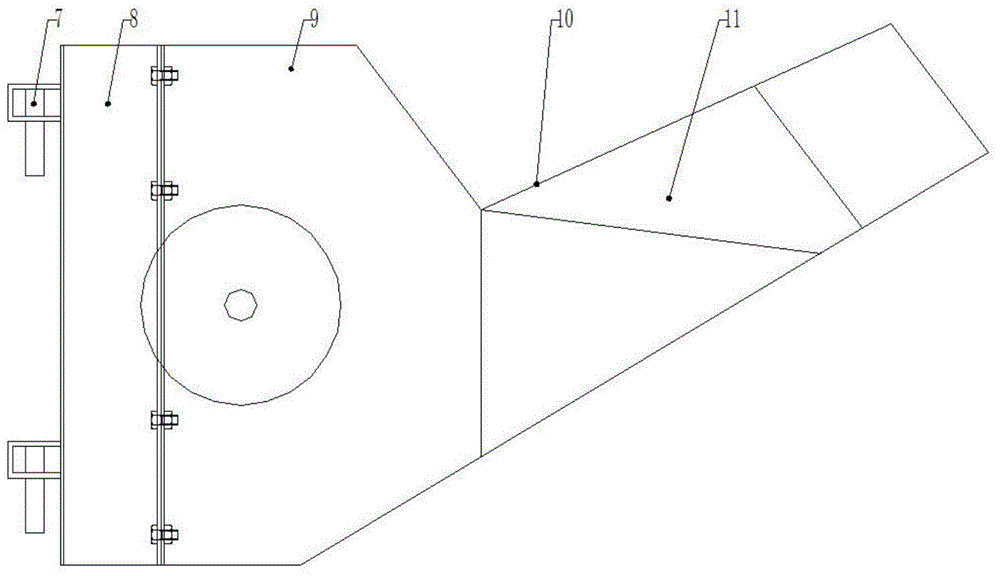

[0024] This embodiment provides a straw chopping, throwing, and returning machine for combine harvesters. The straw chopping, throwing, and returning machine for combine harvesters in this embodiment is used in conjunction with a wheeled combine harvester. If the structure is as follows figure 1 , figure 2 As shown, it includes a pulley 1, a cutter shaft 2 and a protective casing. The pulley 1 is fixed on the end of the cutter shaft 2 through a key connection. The cutter shaft 2 traverses the protective casing and is fixed inside the protective casing. It also includes a cutter roller The assembly 3 and the fixed knife group 6, the knife roller assembly 3 is connected and fixed with the casing 9 through bearings and flanges, and the knife roller assembly 3 includes the knife magazine 4 and the chopping knife 5, and the knife roller assembly 3 is cylindrical structure, the chopping knife 5 is a double-edged trapezoidal blade, one end of which is installed on the knife magazine...

Embodiment 2

[0028] This embodiment provides a straw chopping, throwing, and field returning machine for combine harvesters. The straw chopping, throwing, and field returning machine for combine harvesters in this embodiment is used in conjunction with Chery combine harvesters. If the structure is as follows figure 1 , figure 2 As shown, it includes a pulley 1, a cutter shaft 2 and a protective casing. The pulley 1 is fixed on the end of the cutter shaft 2 through a key connection. The cutter shaft 2 traverses the protective casing and is fixed inside the protective casing. It also includes a cutter roller The assembly 3 and the fixed knife group 6, the knife roller assembly 3 is connected and fixed with the casing 9 through bearings and flanges, and the knife roller assembly 3 includes the knife magazine 4 and the chopping knife 5, and the knife roller assembly 3 is cylindrical structure, the chopping knife 5 is a double-edged trapezoidal blade, one end of which is installed on the knife...

Embodiment 3

[0032] This embodiment provides a straw chopping, throwing and returning machine for a combine harvester. The straw cutting and throwing returning machine for a combine harvester in this embodiment is used in conjunction with a Yanmar combine harvester. Its structure is as follows figure 1 , figure 2As shown, it includes a pulley 1, a cutter shaft 2 and a protective casing. The pulley 1 is fixed on the end of the cutter shaft 2 through a key connection. The cutter shaft 2 traverses the protective casing and is fixed inside the protective casing. It also includes a cutter roller The assembly 3 and the fixed knife group 6, the knife roller assembly 3 is connected and fixed with the casing 9 through bearings and flanges, and the knife roller assembly 3 includes the knife magazine 4 and the chopping knife 5, and the knife roller assembly 3 is cylindrical structure, the chopping knife 5 is a double-edged trapezoidal blade, one end of which is installed on the knife magazine 4 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com