Dynamic modeling method for syngas one-step dimethyl ether preparation

A dynamic modeling, DME technology, used in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

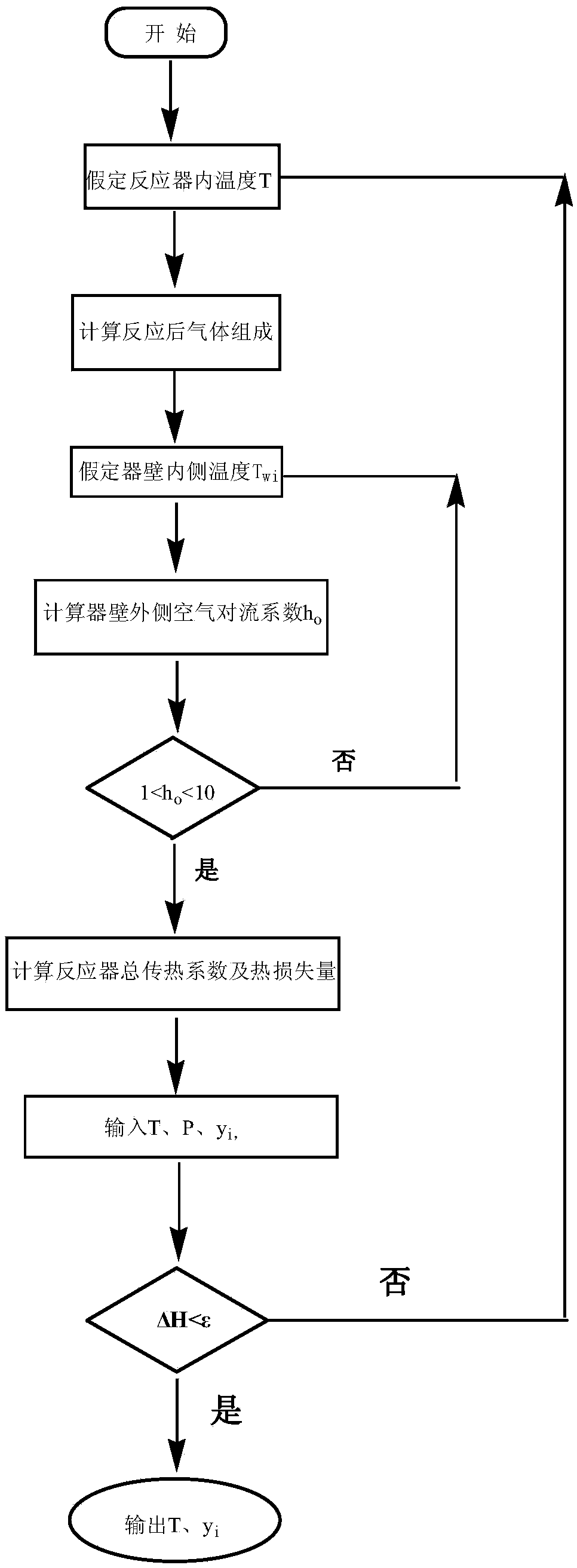

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

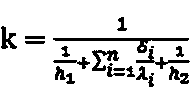

[0058] The object of the present invention is to propose a dynamic modeling method for the one-step synthesis of dimethyl ether from synthetic gas, which regards the feed and discharge conditions of the reactor as non-stable quantities, and solves the kinetic equation at a certain temperature according to the kinetic equation of atomic conservation and reaction. The material composition inside the reactor, the heat loss is introduced into the energy balance equation for the first time, and the temperature in the reactor is solved through the balance equation.

[0059] Under the action of a composite catalyst, the main reactions of syngas one-step direct synthesis of dimethyl ether include methanol synthesis, methanol dehydration and water-gas shift reaction:

[0060] Methanol synthesis reaction: CO+2H 2 CH 3 Oh

[0061] Methanol dehydration reaction: 2CH 3 Oh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com