A Double Ellipse Exponentially Decaying Volume Heat Source Model for Simulating High Energy Beam Welding

A technology of high-energy beam welding and heat source model, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as the difficulty of determining the energy distribution coefficient of the heat source and the inability to reflect the keyhole penetration effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

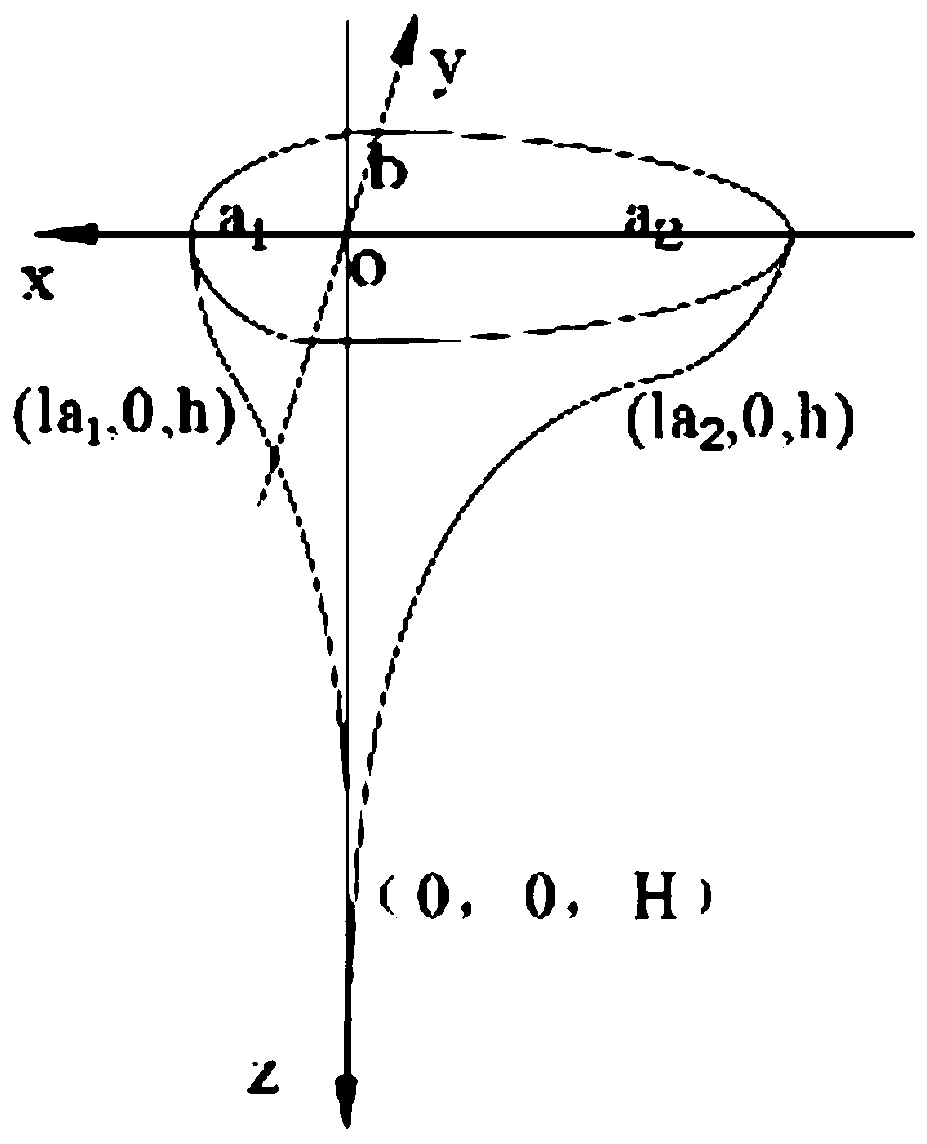

[0142] Such as figure 1 As shown, the shape parameters of the heat source model of the double ellipse exponential decay body described in this embodiment include the length of the front semi-axis a 1 , the length of the rear semi-axis a 2 , molten pool width b, inflection point penetration h, proportional coefficient between inflection point and axial length l, molten pool penetration H. Among them, the parameters other than the ratio coefficient l between the inflection point and the axial length can be measured according to the anatomical topography of the actual test weld, l can be measured by the transverse length at the inflection point of the actual weld anatomical topography and the corresponding semi-axis length a The ratio is obtained.

specific Embodiment approach 2

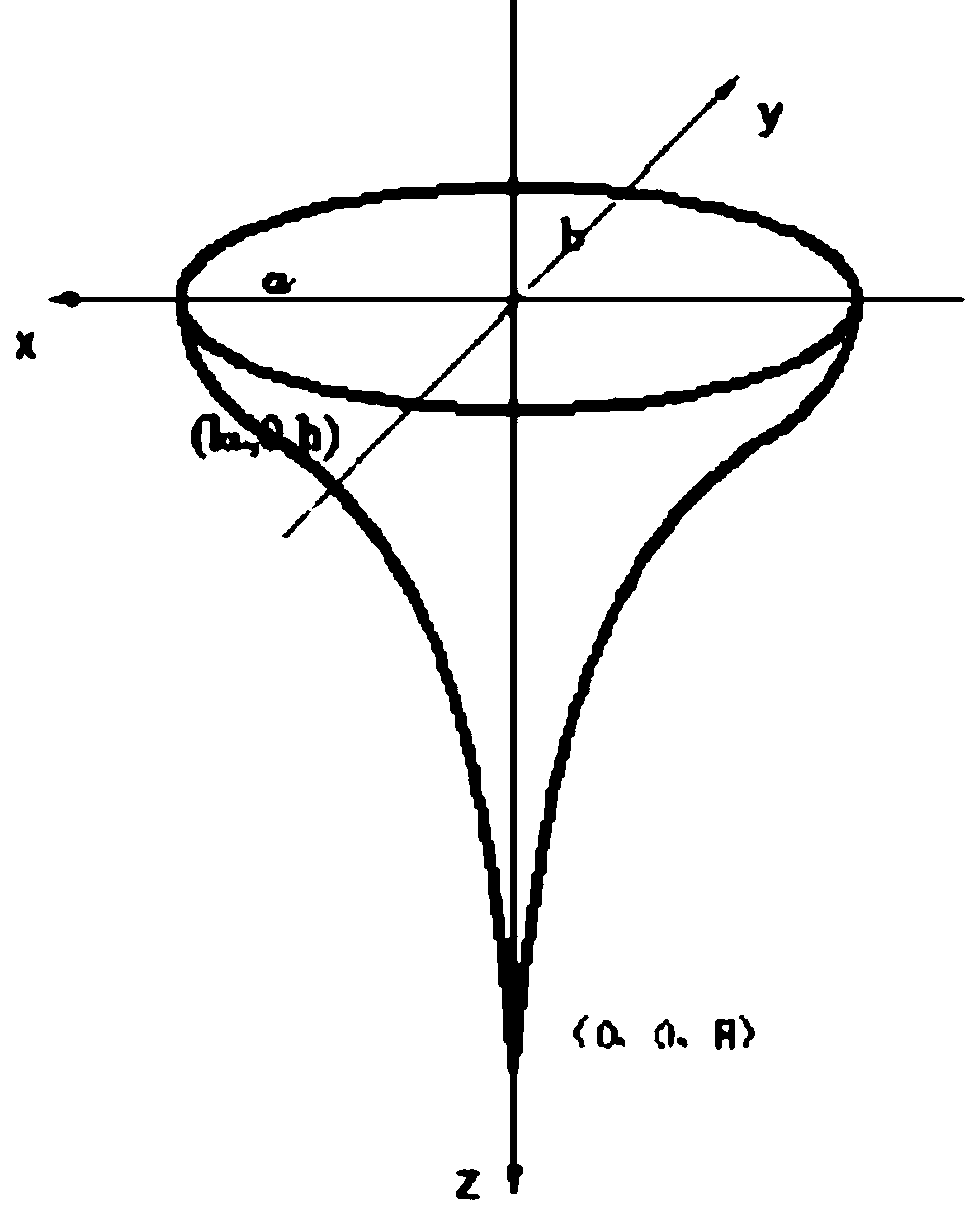

[0143] Such as and As shown, the energy distribution of the first half and the second half of the molten pool described in this embodiment is determined according to the length of the front semi-axis and the length of the rear semi-axis, and the energy distribution ratio of each part is the semi-axis length of the corresponding part and the semi-axis of the front and rear parts The ratio of length and .

specific Embodiment approach 3

[0144] According to the anatomical appearance of the actual test weld, the shape parameters of the heat source model of the double ellipse exponential decay volume are obtained, combined with the actual power of high-energy beam welding, and substituted into

[0145]

[0146]

[0147]

[0148]

[0149] , the corresponding heat flow expression can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com