Sample loading system for automatically transferring samples to analysis device

An analysis device and loading system technology, applied in the direction of analysis materials and instruments, can solve the problems of complex device structure and high failure rate, and achieve the effects of reliable operation, miniaturization of the system, and convenient extension and expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

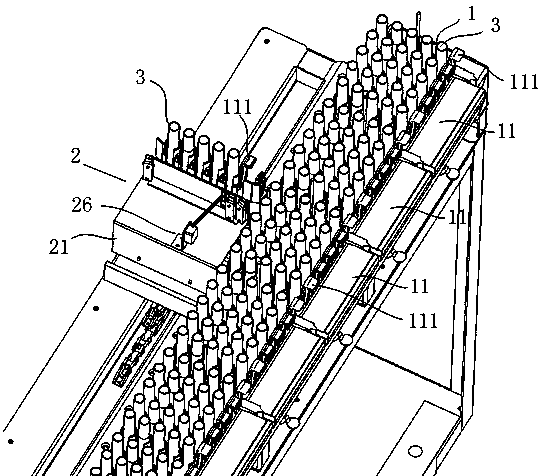

[0043] Embodiment 1: The loading and unloading mechanism 24 is a pick-up mechanism that can extend from the bottom of the sample rack bar 111 to the tail end of the sample rack bar 111 to drag the sample rack bar 111 from the sample rack group 11 into the transfer channel 23 Elevating hook mechanism; the specific structure of the lifting hook mechanism includes a lifting hook body and a material retrieving drive mechanism that drives the lifting hook to move horizontally. A stepping motor can be used to connect with the feeding drive mechanism, and the lifting hook body can be controlled to swing from head to toe under the drive of the stepping motor; , the stepping motor drives the front end of the lifting hook body to rise, hooks the tail end of the sample holder bar 111, and the driving mechanism for taking materials drives the lifting hook body to move horizontally. 111 is also dragged out from the sample holder group 11 along with the lifting hook body, and dragged to the...

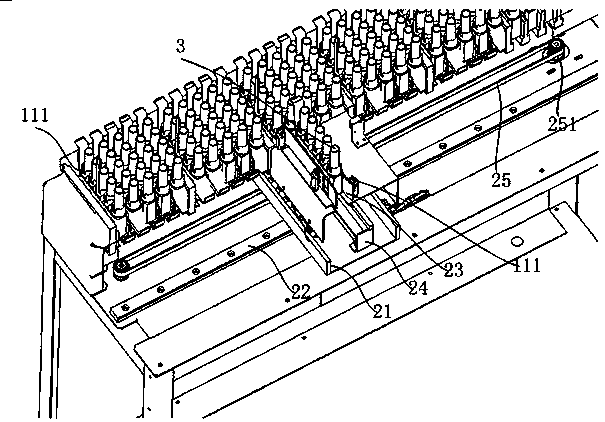

Embodiment 2

[0044] Embodiment two, combining Figure 5 As shown in , the loading and unloading mechanism includes a material transfer groove 241 that is engaged with the bottom of the sample holder bar 111. The bottom of the material transfer groove 241 is provided with a lifting mechanism, and the bottom of the lifting mechanism is provided with a driving material transfer groove. The groove holds up the material-taking drive mechanism for the sample rack bar 111 to move between the transfer channel 23 and the sample rack set 11 . Before the sample rack bar 111 needs to be moved, the feeding drive mechanism first moves the material transfer groove 241 into the bottom of the sample rack bar 111, lifts the material transfer groove 241 through the lifting mechanism, lifts the sample rack bar 111 to an appropriate height, and then passes The material-taking driving mechanism moves horizontally, and the material-moving groove 241 is lowered after the horizontal movement is completed. In the ...

Embodiment 3

[0045] Embodiment three, combining Image 6 As shown in , the bottom of the sample support bar 111 is provided with a positioning groove 112, and the loading and unloading mechanism includes a lifting lever 242 that cooperates with the positioning groove 112, and the bottom of the lifting lever 242 is provided with There is a material-taking drive mechanism that moves the sample rack bar 111 to move between the transfer channel 23 and the sample rack set 11 . The working principle of this method is basically the same as that of the above-mentioned method 2, except that there is no need to lift the sample support bar 111 and directly drag it horizontally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com