Plate-fin heat exchanger

A heat exchanger and plate-fin technology, applied in the field of plate-fin heat exchangers, can solve the problems of high manufacturing difficulty and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

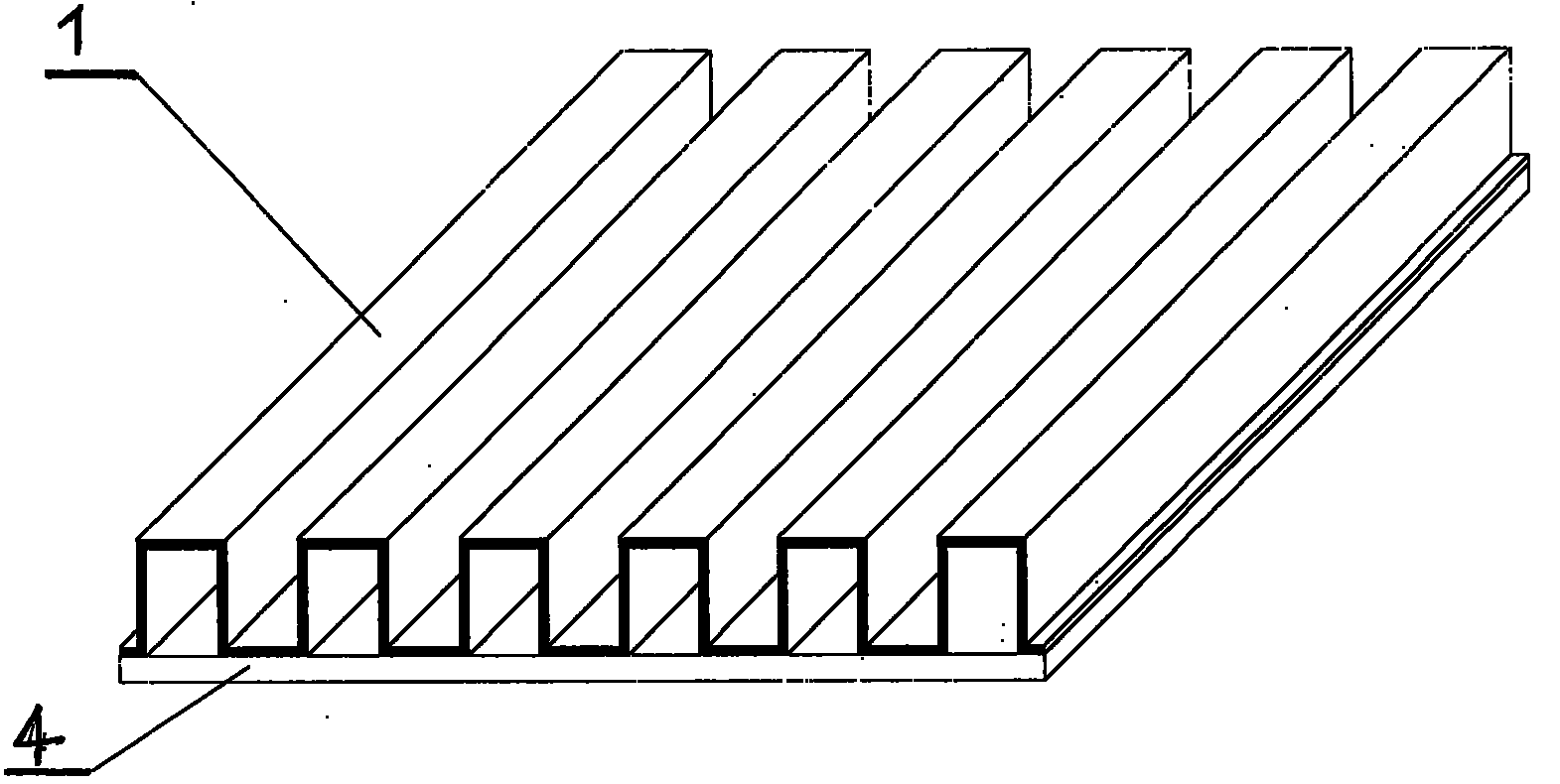

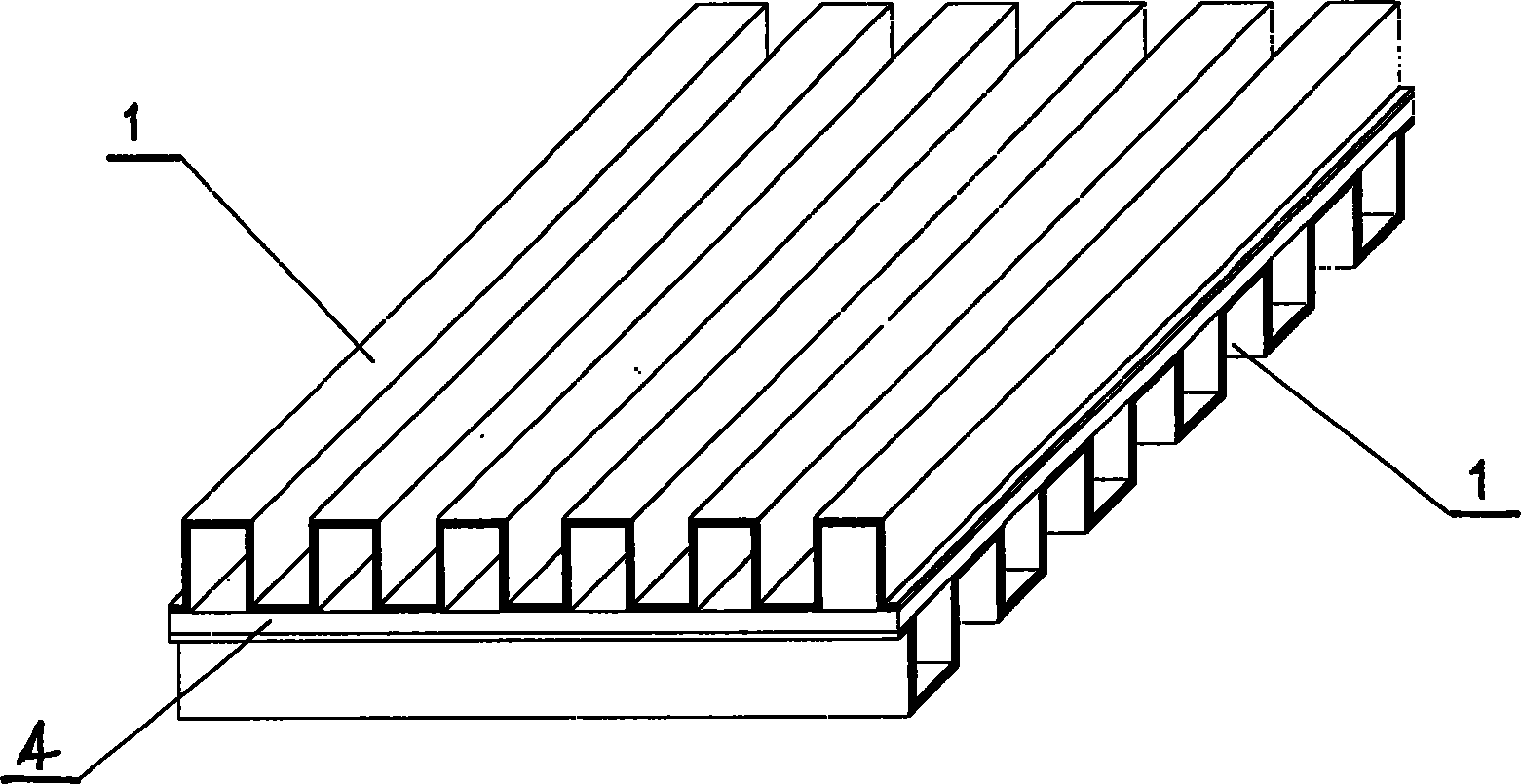

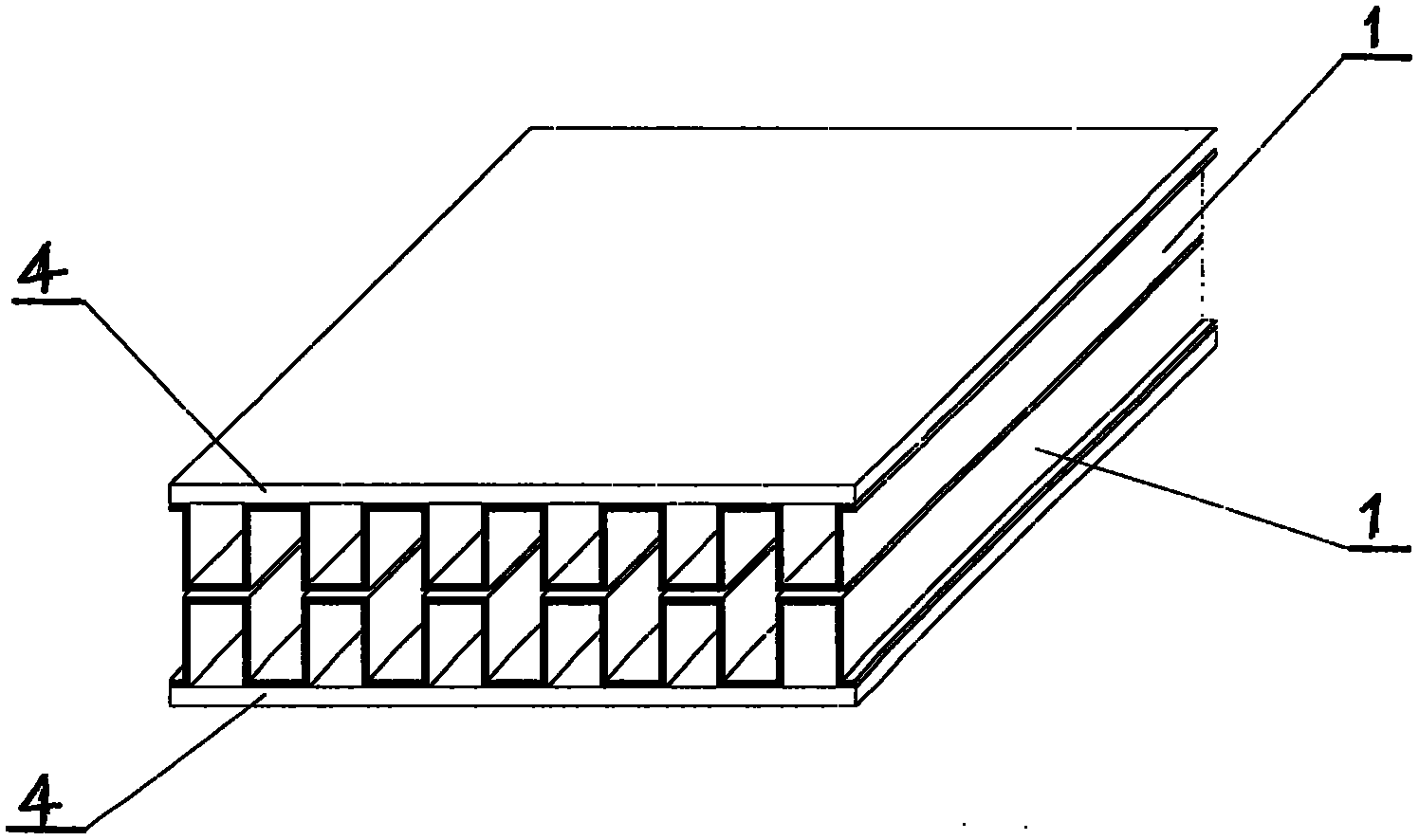

[0014] Figure 4 For a "middle partition-fin structure" (8) figure of the present invention, from Figure 4 It can be seen that the "middle partition-fin structure" (8) is composed of a middle partition (4) and two fins (1) attached to its two sides, and the two fins on the front and back sides of the middle partition (4) The sheets (1) are arranged in a 90-degree cross arrangement; Figure 5 It is the "outer partition-fin structure" (7) figure of the plate-fin heat exchanger of the present invention, from Figure 5 It can be seen that the "outer partition-fin structure" (7) is composed of the outer partition (7) and two fins (1) attached to its two sides; from Figure 4 and Figure 5 It can be seen that the combination of fins (1) and intermediate partitions (4) can be carried out independently, and the combination of each intermediate partition (4) and fins (1) is very clearly visible, which is conducive to inspection. Poor quality is also easy to replace without affecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com