Opening frame and box matching structure of food refrigeration display cabinet

A food refrigeration and matching structure technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of low work efficiency, troublesome operation, dew condensation and energy saving, etc., achieve reasonable structure, high assembly efficiency, and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

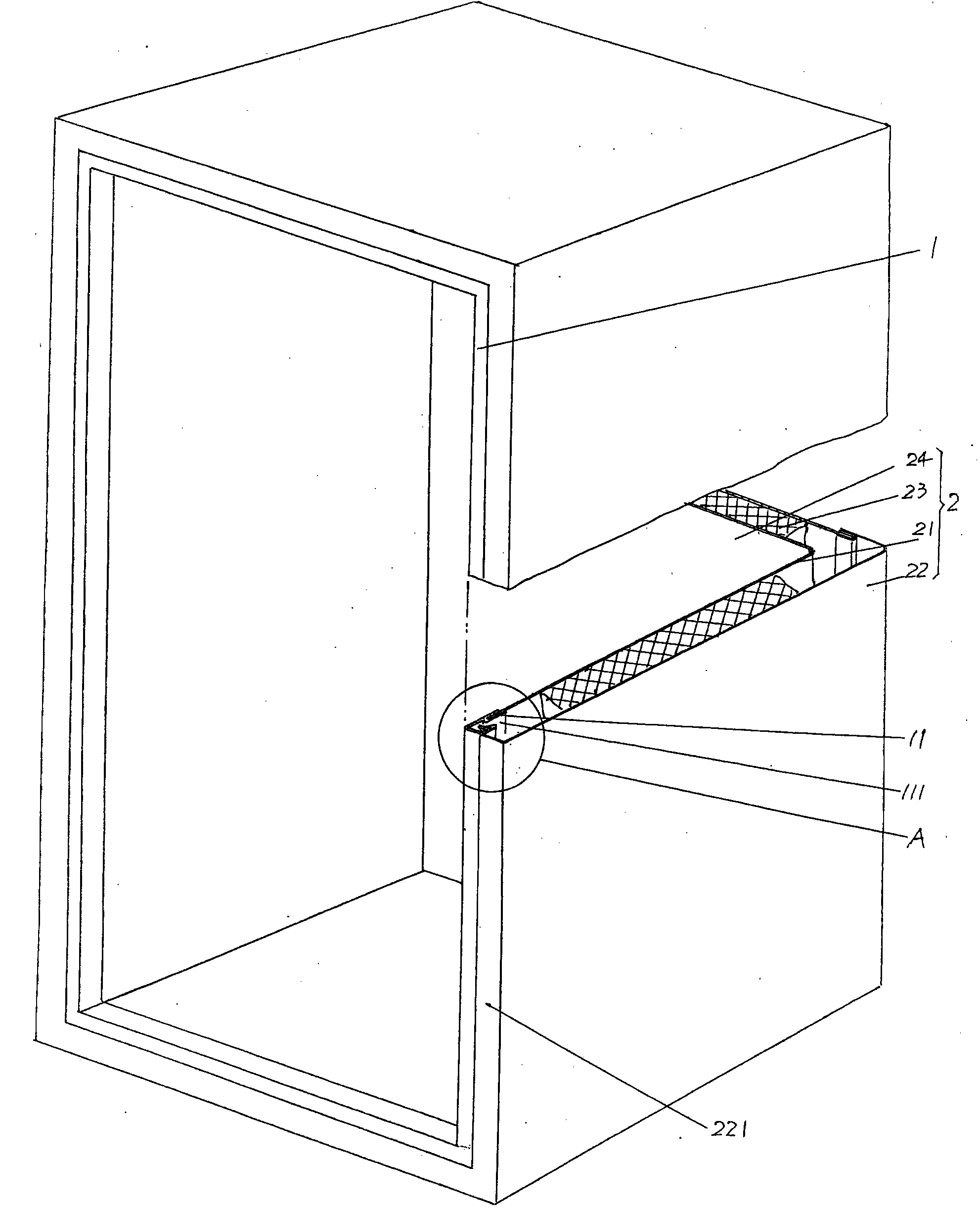

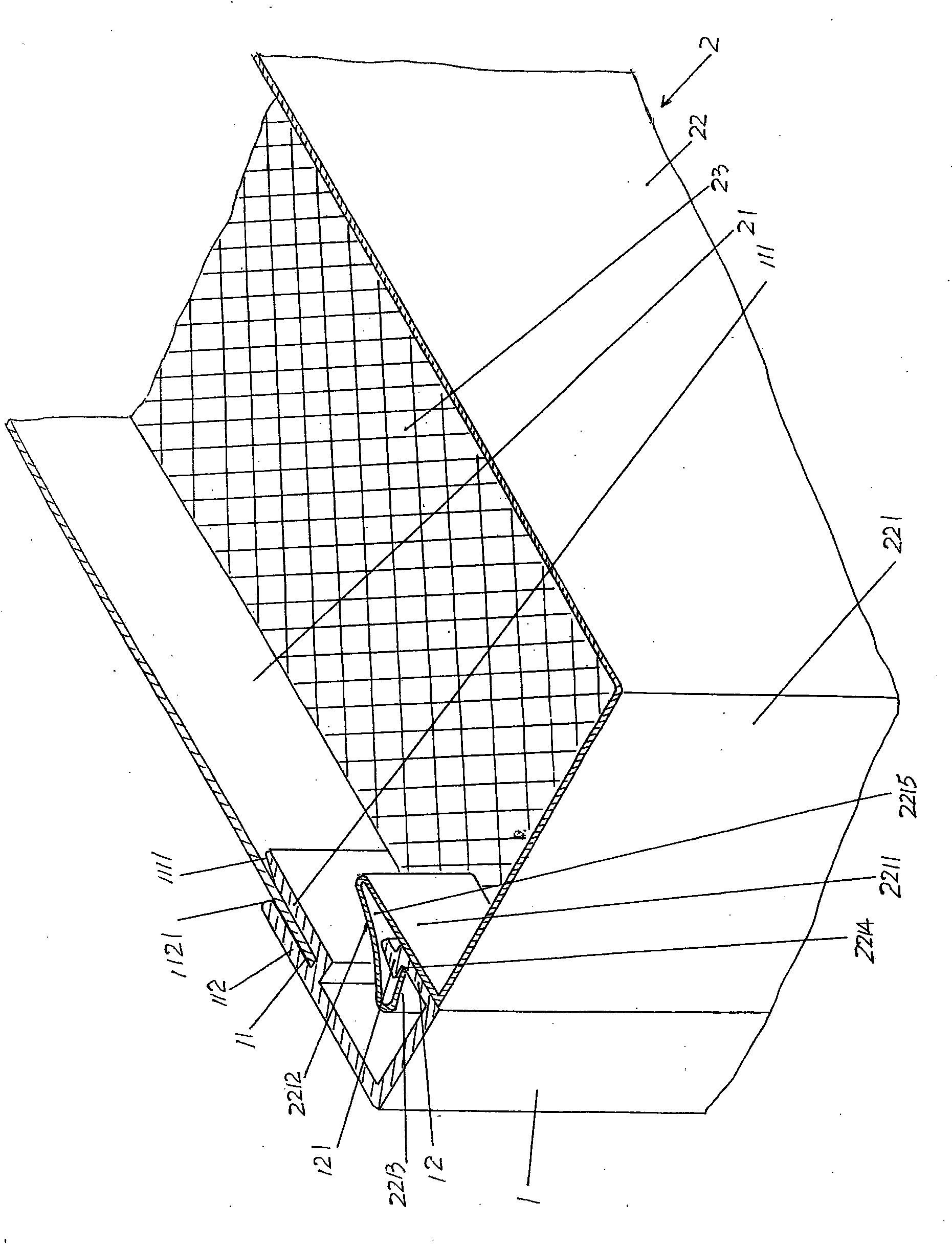

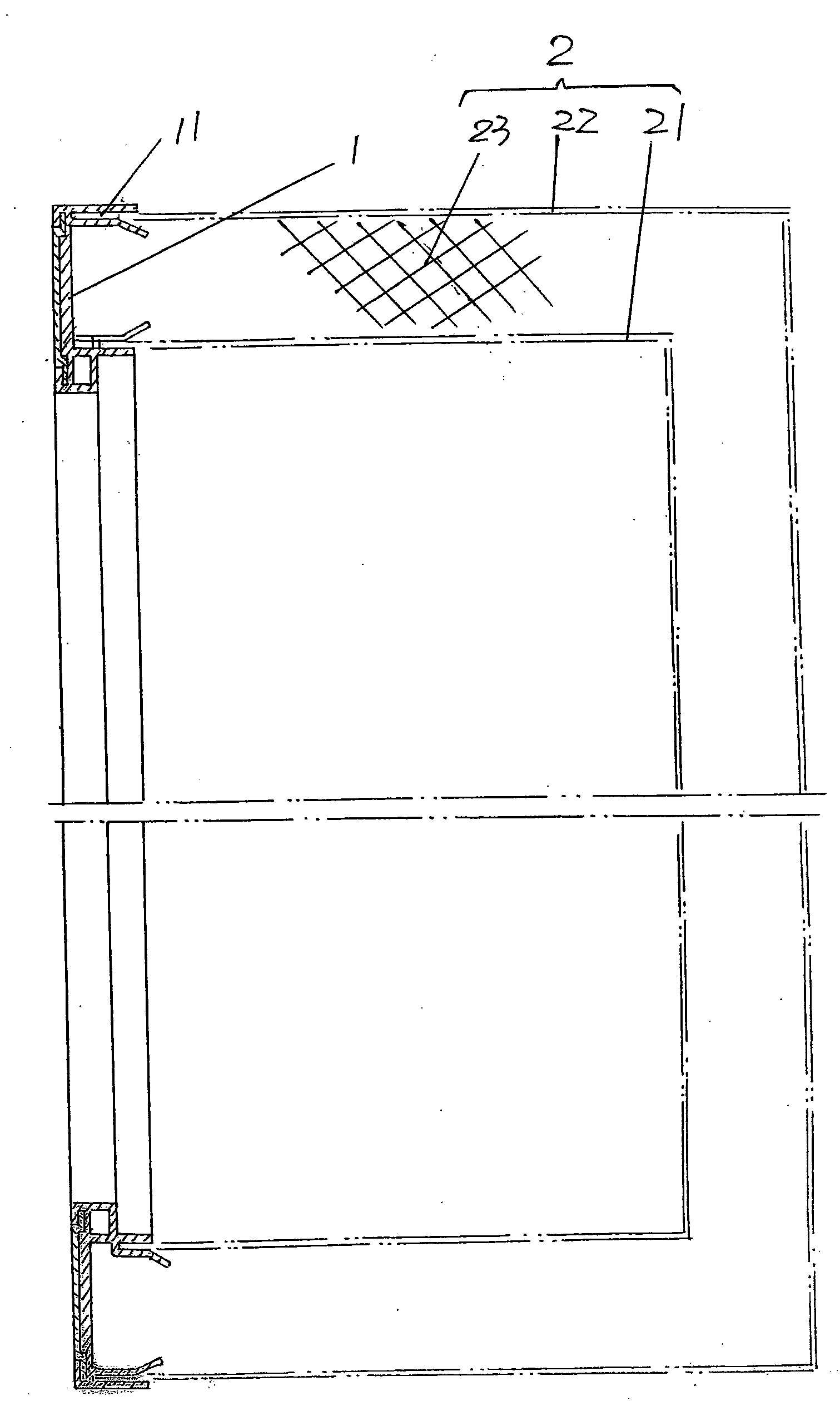

[0021] See figure 1 and figure 2 , provides a frame body 1 made of plastic and can be obtained by mold making, the frame body 1 is formed with a box slot 11; a box body 2 is provided, and the box body 2 includes an inner tank 21. The outer shell 22 and the foam insulation layer 23 are made of a metal inner liner 21 and the position corresponding to the opening of the box body cavity 24 of the box body 2 is inserted and fitted with the box slot 11, The surrounding edges of the shell 22 made of metal form a shell flanging 221 at a position corresponding to the mouth of the box body cavity 24, the shell flanging 221 is matched with the mouth frame body 1, and the foam insulation layer 23 is located Between the liner 21 and the shell 22 .

[0022] As the technical gist of the technical solution provided by the present invention: a mouth frame matching flange 2211 is formed on the side of the aforementioned shell flange 221 facing the aforementioned mouth frame body 1 and in a ...

Embodiment 2

[0028] Only the height of the first slot wall 111 is changed to 1.5 cm, and the height of the second slot arm 112 is changed to 1 cm. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com