A Reed Axial Insertion Type Overrunning Clutch

An overrunning clutch, plug-in technology, used in one-way clutches, clutches, mechanical equipment, etc., can solve the problems affecting the reliability and service life of the overrunning clutch, the difficulty of assembling the compression spring, and increasing the production cost. And the effect of good radial positioning, fast roller movement and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

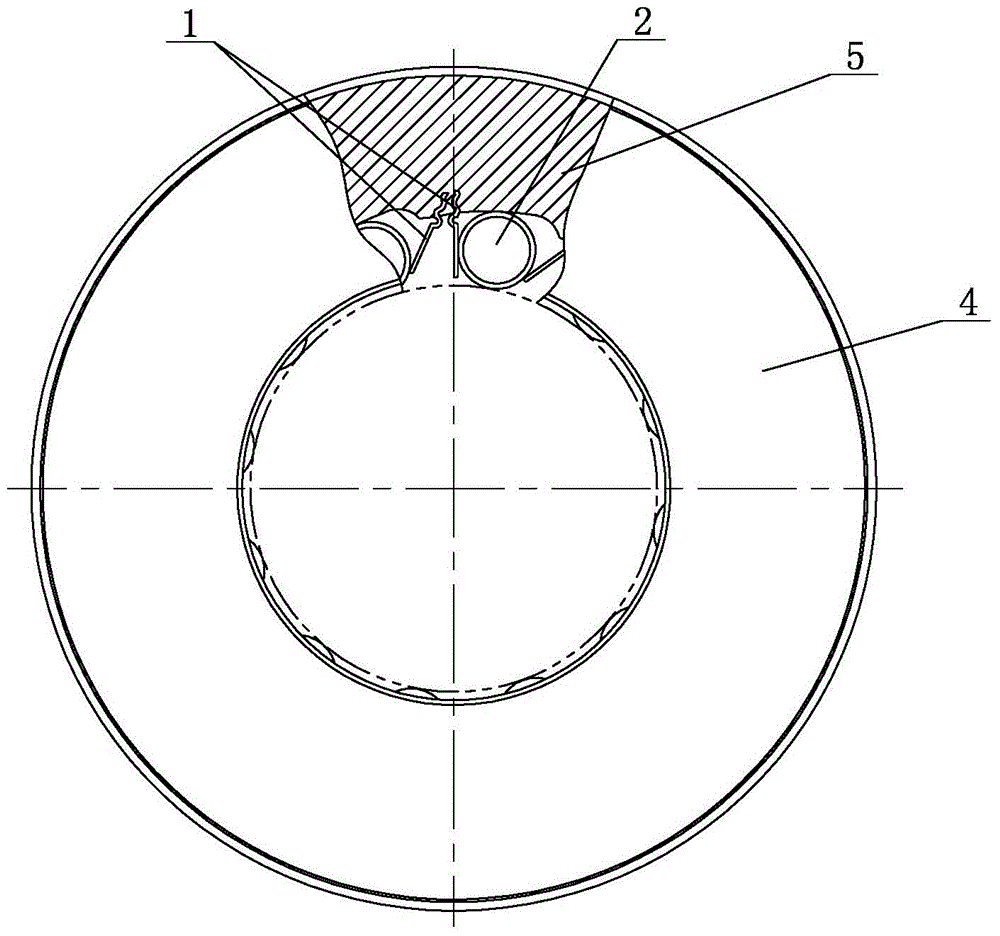

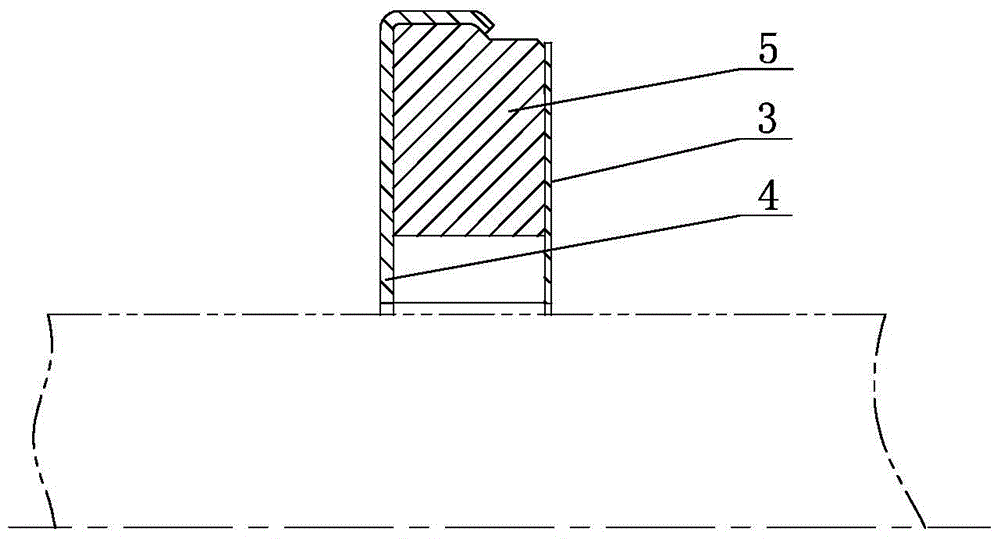

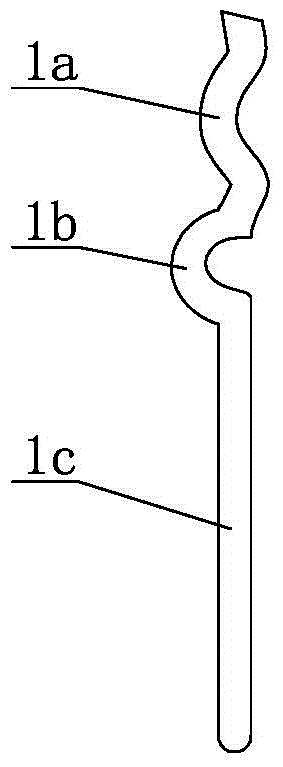

[0014] Such as figure 1 , figure 2 As shown, the present invention is made of parts such as elastic driver, roller 2, baffle plate 3, shield 4 and body 5. Wherein, the main body 5 is a ring structure, and the protective cover 4 is installed on one side of the main body 5, and the baffle plate 3 is installed on the other side, and the baffle plate 3 and the protective cover 4 are fixed to the main body 5. The inner wall of the main body 5 is provided with wedge-shaped positioning grooves uniformly distributed on the circumference, and the number of wedge-shaped positioning grooves is 6-16, preferably 12 in this embodiment. A roller 2 is installed in each wedge-shaped positioning groove, and the axis line of the roller 2 is parallel to the axis line of the body 5 . The roller 2 is limited by the baffle 3 and the shield 4, so that the roller 2 can only move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com