Engine all-cylinder nonuniformity compensation control method based on indicated torque

A compensation control, uniformity technology, applied in the direction of engine control, machine/engine, electrical control, etc., can solve problems such as non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

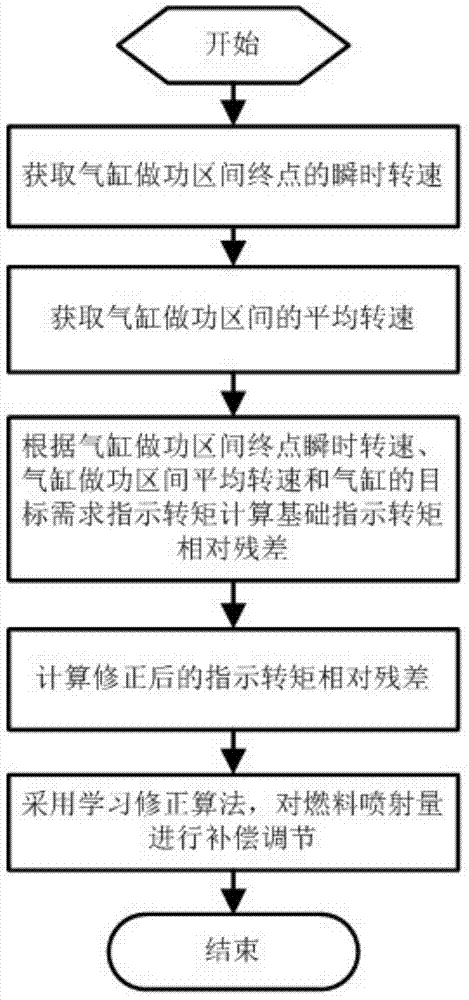

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

[0027] In order to introduce the content of the present invention in detail, some related concepts are defined:

[0028] Definition 1: Indicated torque refers to the output torque of the crankshaft equivalent to the indicated work obtained by converting the heat and power of one working cycle of the cylinder, expressed as Trq I express.

[0029] Definition 2: Indicated torque residual refers to the difference between the average indicated torque and the reference indicated torque in the working range of the cylinder, where the reference indicated torque is the target demand indicated torque under this working condition. The indicated torque residual brings about the fluctuation of the crankshaft speed before and after the work interval.

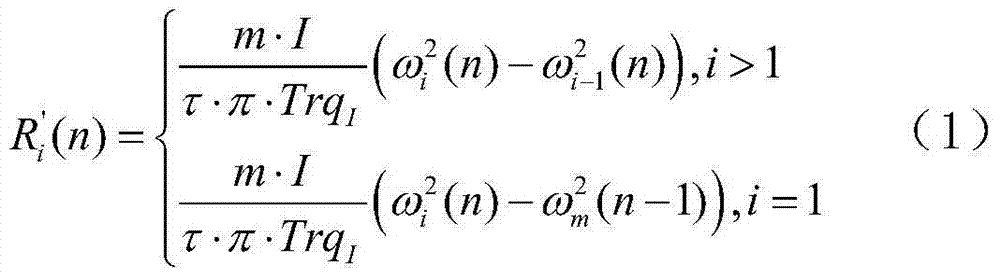

[0030] Definition 3: The relative residual of indicated torque refers to the ratio of indicated torque residual to target demand indicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com