Monitoring method of annulus displacement efficiency in simulated cementing engineering

A technology for displacement efficiency and wellbore simulation, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc. It can solve the problems of large experimental error, poor versatility, and long experimental time, and achieve accurate and reliable displacement efficiency. The effect of strong applicability and field applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for monitoring displacement efficiency of annulus in simulated cementing engineering, comprising the following steps:

[0030] a. Inject the displaced fluid and the displacement fluid with different conductivity into the annular space of the measurement section of the simulated wellbore respectively, wherein the conductivity of the displaced fluid is C 1 , the conductivity of the displacement fluid is C 2 ;

[0031] b. Send excitation current to the annular space of the measurement section, establish a sensitive field in the annular space area of the simulated wellbore measurement section, and collect voltage signals;

[0032] c. The conductivity information of each point in the sensitive field is obtained by calculating the voltage signal, so that the conductivity at different periods is C 1 of the displaced fluid and a conductivity of C 2 The respective volumes occupied by the displacement fluids in the annular space of the simulated wellbore measurement...

Embodiment 2

[0046]This embodiment further illustrates the present invention in conjunction with the accompanying drawings. The present invention comprises the following steps:

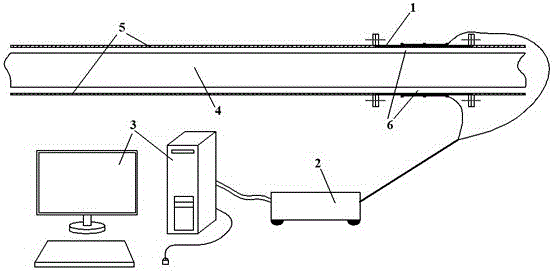

[0047] 1) The ERT system including the electrode sensor group 1, the electrical resistance tomography host 2 and the computer 3 is used as the measurement equipment. The electrode sensor group 1 of the ERT system is arranged in the measurement section of the simulated wellbore. It is required that the electrode sensor group 1 and the outside of the simulated wellbore The pipes 5 are connected by flanges, and the inner pipe 4 of the simulated wellbore is located in the outer pipe 5 of the simulated wellbore;

[0048] 2) Inject the displaced fluid (drilling fluid, etc.) and displacement fluid (spacer fluid or cement slurry, etc.) into the annular space of the measurement section formed by the simulated wellbore inner pipe 4, the simulated wellbore outer pipe 5, and the electrode sensor group 1, respectively, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com