Device for enhancing color stability of solvent oil

A stable, solvent oil technology, applied in the petroleum industry, processing hydrocarbon oil, and multi-stage series refining process treatment, etc., can solve the problems of high equipment investment and production costs, harsh process conditions, and moderate process conditions, and achieves Satisfied color stability, simple process, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

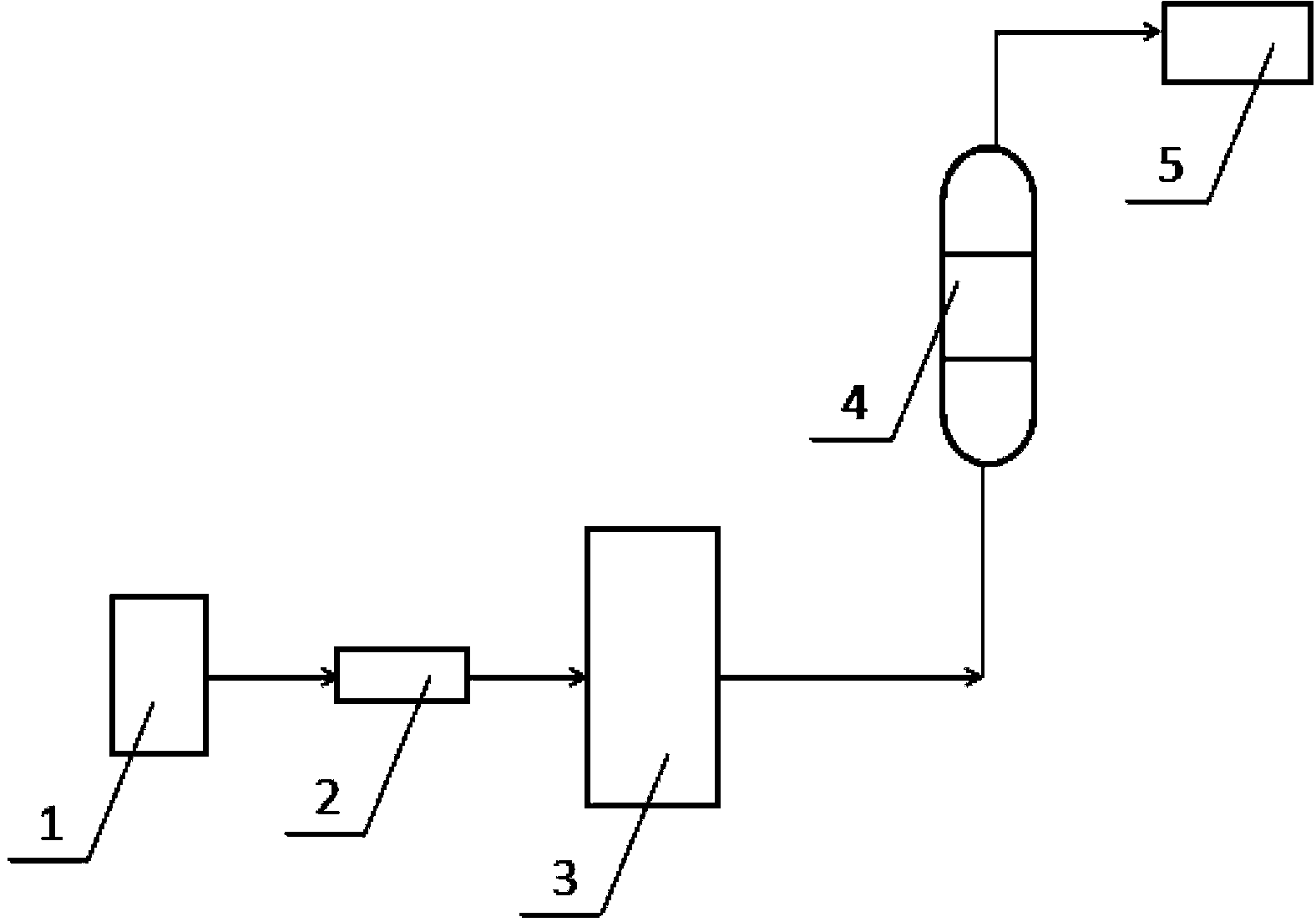

[0014] like figure 1 As shown, the device that improves the color stability of solvent oil, comprises settling tank 1, filter 2, dehydrator 3, fixed bed reactor 4 filled with adsorbent, solvent oil finished product storage tank 5, described settling tank 1, filter Device 2, dehydrator 3, fixed bed reactor 4 filled with adsorbent, and storage tank of solvent oil product 5 are connected in sequence through pipelines.

[0015] The adsorbent uses activated carbon as a carrier, and the active ingredient is an adsorbent for inorganic salts of iron, cobalt, tin and titanium.

[0016] In the present invention, the crude oil passes through the sedimentation tank 1 and the filter 2 to remove solid impurities, then passes through the dehydration effect of the dehydrator 3, and then passes through the fixed bed reactor 4, and the basic nitride is removed through the adsorption effect of the adsorbent. Therefore, the obtained solvent oil finished product has few impurities, high quality a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com