Bulk cargo gathering device, bulk cargo car loader and loading method

A technology for loading machines and bulk materials, which is applied in the field of construction machinery, and can solve problems such as high energy consumption of reciprocating motion, flying dust and noise pollution, and inapplicability of loaders, so as to reduce energy consumption, reduce pollution, and improve loading efficiency efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

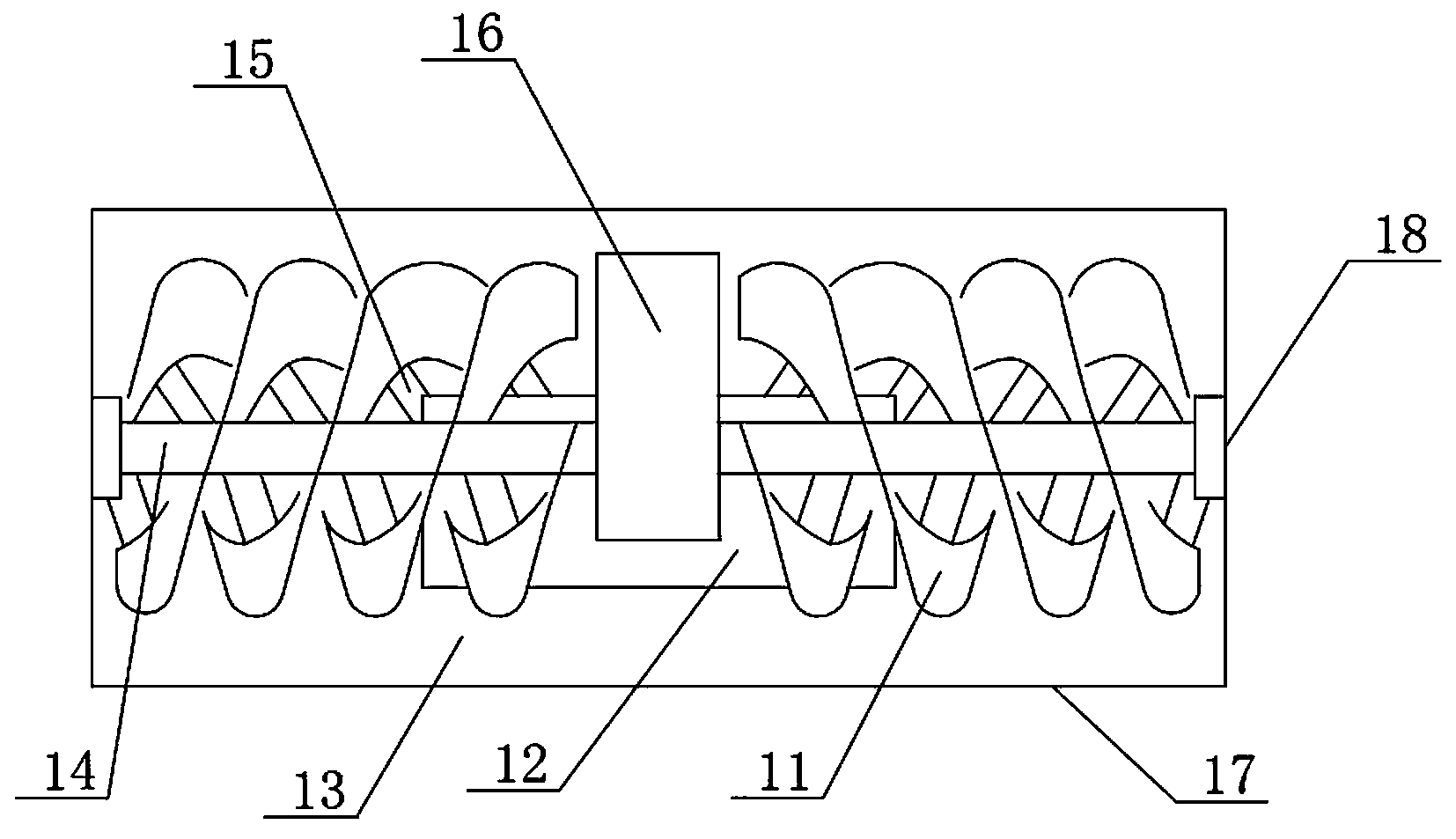

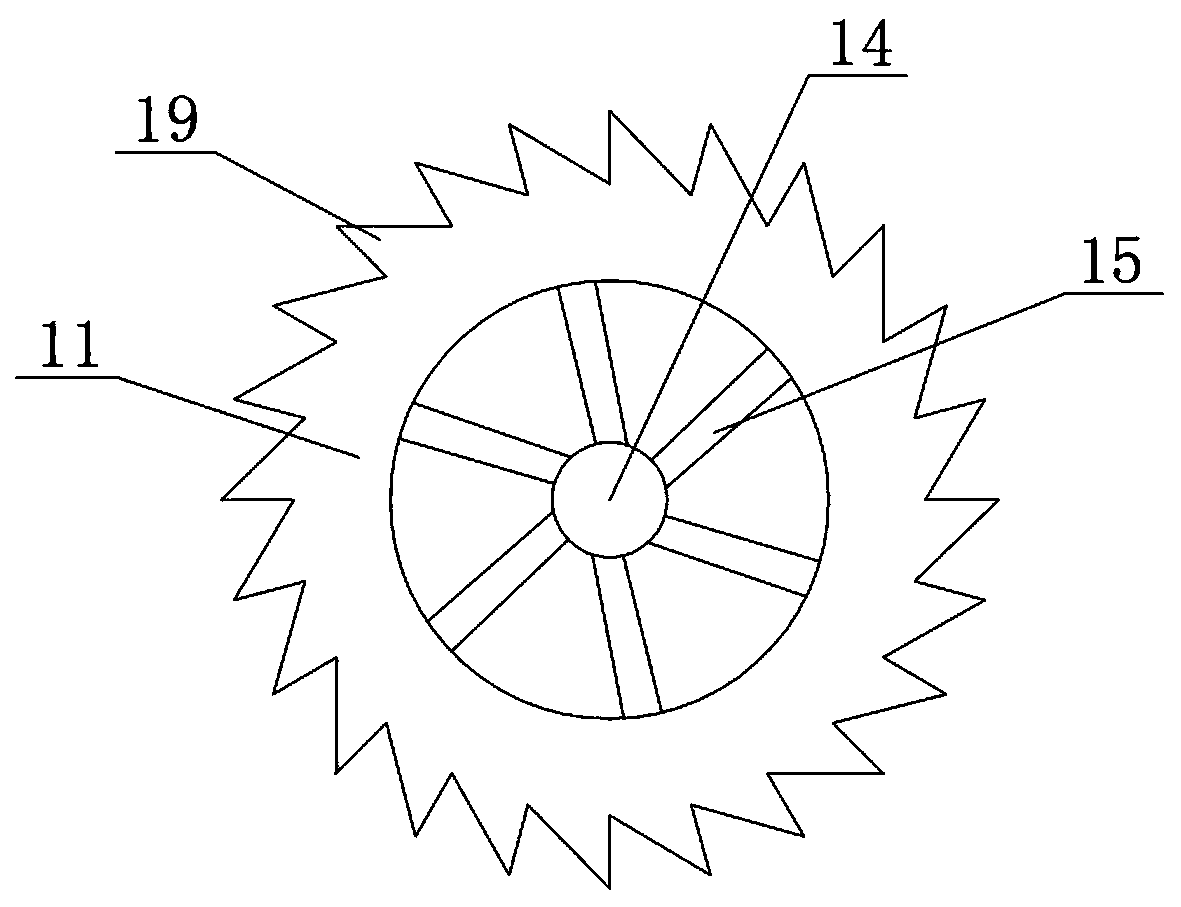

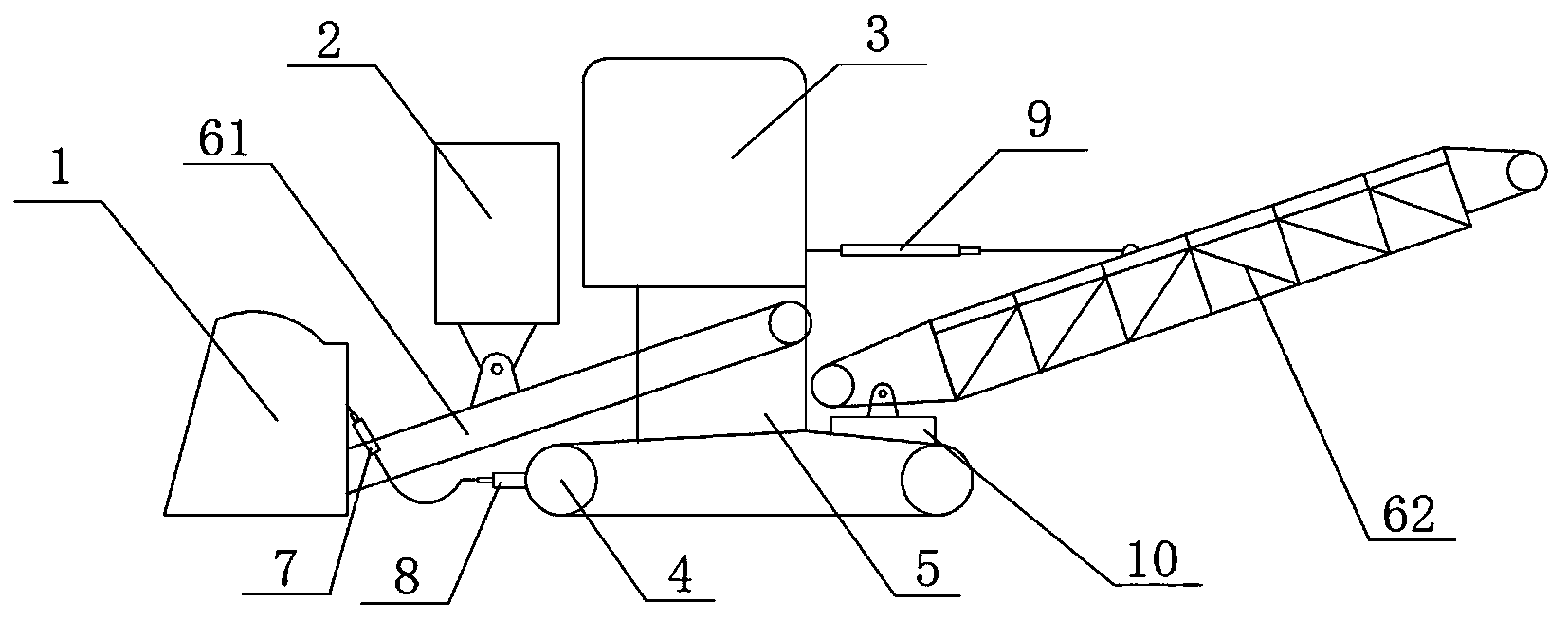

[0022] see Figure 1-Figure 4 , a bulk material gathering device of the present invention, comprising a gathering bucket composed of an inclined bottom plate 17, an upper arc-shaped plate 13 and two side plates 18, the angle α between the inclined bottom plate 17 and the horizontal plane is 10°~30°, and the The middle part of the upper arc-shaped plate 13 is provided with a discharge port 12 communicating with the bulk material conveying device, and a rotating shaft 14 is arranged between the two side plates 18 of the folding bucket, and a gearbox 16 is arranged in the middle of the rotating shaft 14, so that The rotating shaft 14 is divided into two semi-shafts by the gearbox 16. The rotating shaft 14 is provided with hollow helical blades 11 arranged symmetrically and obliquely along the gearbox 16. The hollow helical blades 11 all face the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com