A waterproof turnover box

A turnover box and box cover technology, used in rigid containers, locking equipment, closing and other directions, can solve the problems of items becoming wet and wet, and there is no waterproof measure at the joint of the box cover, and achieve the effect of enhancing the load-bearing capacity and being less prone to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

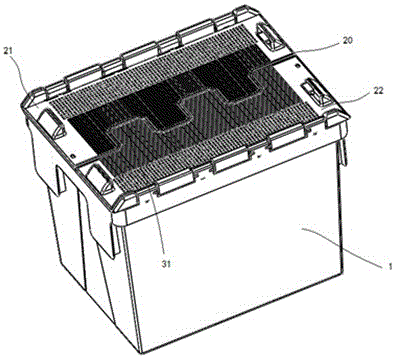

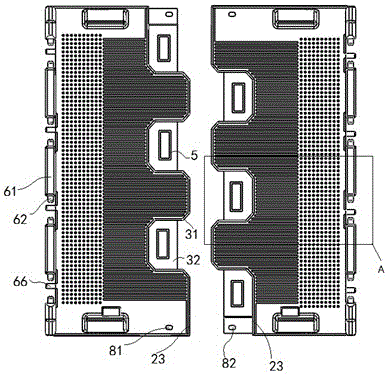

[0045] This embodiment provides a waterproof turnover box, such as Figure 1-6 As shown, a box body 1 comprising an upper opening, and a first box cover 21 and a second box cover 22 respectively rotatably connected to two opposite side walls of the box body 1, the first box cover 21 and the The second case cover 22 is respectively provided with several protruding teeth 31 and concave teeth 32 which can be buckled together when closed, and the lower surfaces of the first case cover 21 and the second case cover 22 are respectively provided with There are a first protruding band 41 and a second protruding band 42. The outwardly protruding bent part of the first protruding band 41 or the second protruding band 42 is closed at the upper end and opened at the lower end to form the protruding tooth 31. The upper end of the inwardly concave bent part of the belt 41 or the second convex belt 42 is open and the lower end is closed to form the concave tooth 32 , the open lower end of the...

Embodiment 2

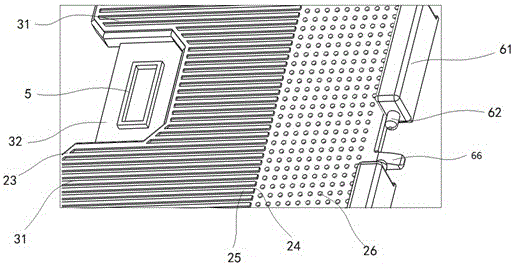

[0051] This embodiment provides a waterproof turnover box, which is an improvement on the basis of Embodiment 1, the difference is that waterproof measures are further added, such as Figure 7 and Figure 8 As shown, when the first case cover 21 and the second case cover 22 are snapped together, a first seam 20 is formed, and the first case cover 21 and the second case cover near the first seam 20 22 are respectively provided with a first blocking convex wall 23 that blocks water falling onto the upper surface of the box body 1 from flowing into the first seam 20 .

[0052] After the water drop falls on the upper surface of the box body 1, under the blocking effect of the above-mentioned first blocking convex wall 23, the water can be prevented from gathering at the position of the first seam 20, and the amount of water flowing to the position of the first seam 20 can be reduced, thereby reducing The waterproof pressure between the above-mentioned two adjacent outer surfaces ...

Embodiment 3

[0054] This embodiment provides a waterproof turnover box, which is an improvement on the basis of Embodiment 1 or 2, the difference is that a flow guide structure is added, such as figure 2 , image 3 , Figure 7 and Figure 8 As shown, a flow guide structure is also provided on the upper surface of the first case cover 21 and the second case cover 22; the flow guide structure includes several bars connected with the first blocking convex wall 23, and The elongated convex wall 25 of the diversion groove 24 is formed between any two adjacent ones.

[0055] The setting of elongated convex wall 25 can make there are less low-lying positions that can accommodate water on the first case cover 21 and the second case cover 22, and water is very easy to collect and flow out in the diversion groove 24, can reduce the second The amount of water stored on the upper surfaces of the first case cover 21 and the second case cover 22 reduces the risk of water leakage. Further, the long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com