Built-in suspended integrated type hub motor drive electric wheel

An in-wheel motor, an integrated technology, applied in motors, electric vehicles, synchronous motors with static armatures and rotating magnets, etc., can solve the problem that the inner rotor structure cannot be realized, increase the variation of the magnetic gap of the motor, and affect the motor. torque performance and other issues, to achieve the effect of improving dynamic characteristics, improving vibration characteristics, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

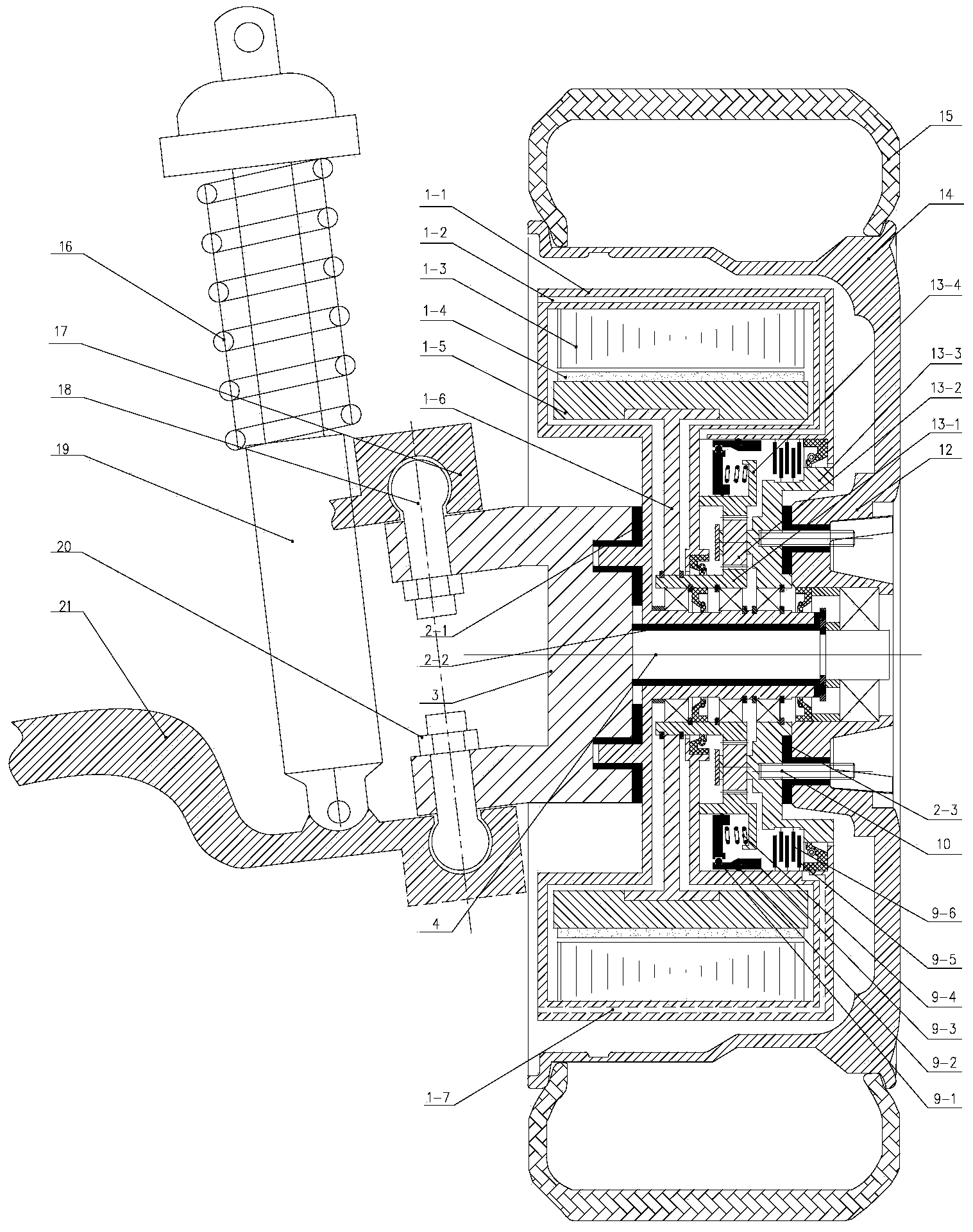

[0038] Such as figure 1 As shown, the built-in suspension integrated in-wheel motor-driven electric wheel in this embodiment includes in-wheel motors, brakes, damping mechanisms, unequal-length double-wishbone independent suspensions and wheels, and the wheels include rims 14, wheel hubs 12, tires 15 etc.

[0039]The damping mechanism includes an elastic element 2-1 and an elastic element 2-2. The in-wheel motor includes an outer stator (including iron core and winding) 1-3, an inner rotor composed of a permanent magnet 1-4 and a rotor yoke 1-5, a housing 1-1, a rotor support frame 1-6, and an outer The stator is fixed on the shell 1-6, the permanent magnet 1-4 is glued to the surface of the rotor yoke 1-5, and the rotor yoke 1-5 is connected to the rotor support frame 1-6 through threads. The housing 1-1 is connected to the joint arm 3 through the first elastic element 2-1, and is connected to the support shaft of the wheel through the elastic element 2-2, which ensures the...

Embodiment 2

[0046] In this embodiment, except that the brake is an electromagnetic brake disc, all the other features are the same as in Embodiment 1.

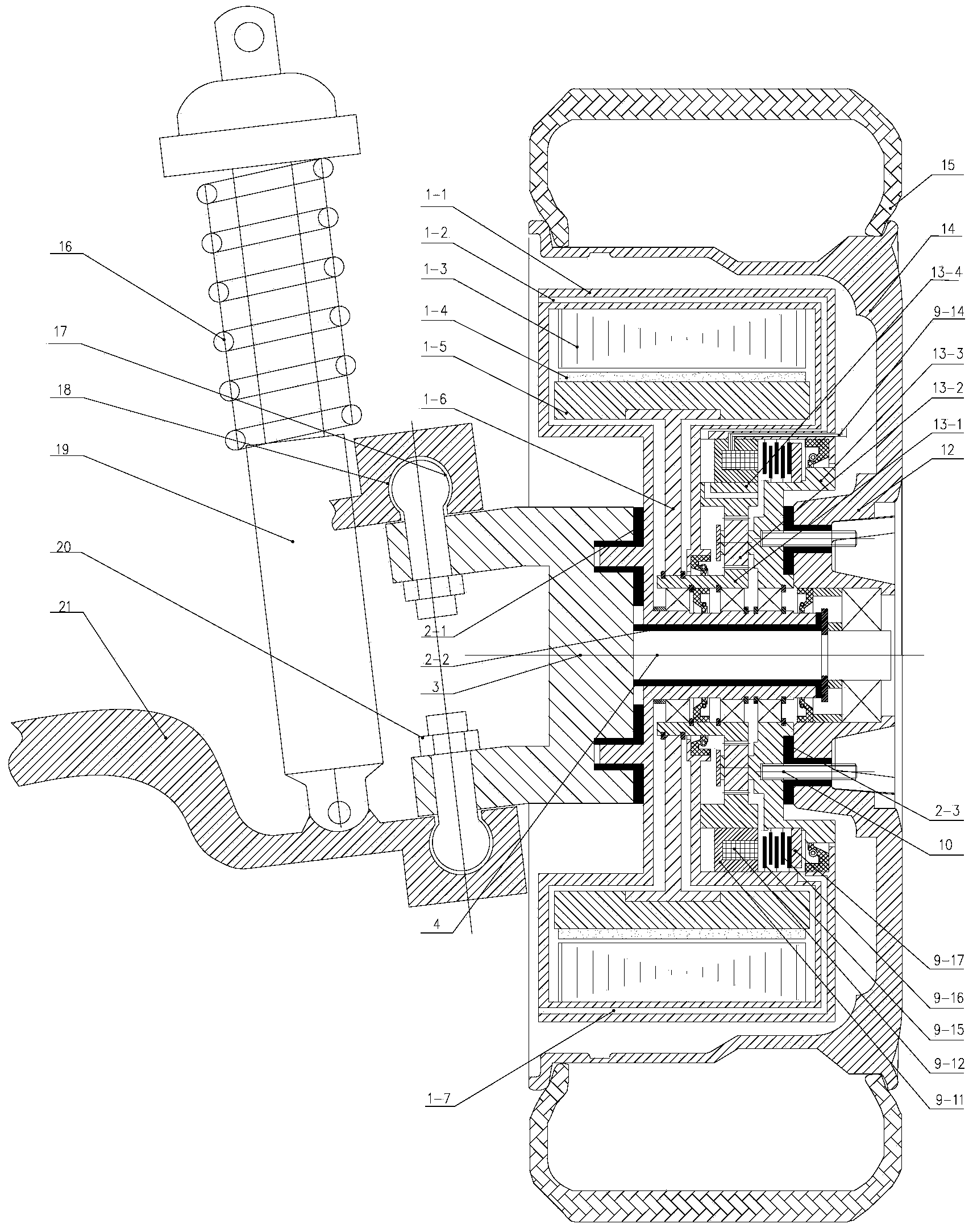

[0047] Such as figure 2 As shown, the brake is a multi-disc electromagnetic brake, including a friction plate 9-16, a pressure plate 9-15, a yoke 9-11, an armature 9-17, and the friction plate 9-16 and the armature 9-17 are mounted on 13-3 on the planet carrier, and rotates with the planet carrier 13-2; the pressure plate is installed on the shell 1-1; coil 9-12 is wound in the inner cavity of the yoke 9-11, and the yoke 9-11 is installed on the In the annular cavity formed by the casing 1-1 and the ring gear 13-4; the lead wire 9-14 of the electromagnetic brake is buried in the surface of the motor casing 1-1. When braking, a current is passed into the coil, and the magnetic field in the yoke attracts the armature to the end of the pressure plate, and presses the pressure plate and the friction plate to achieve braking; when the brake ...

Embodiment 3

[0050] In this embodiment, except that the unequal-length double-wishbone independent suspension is replaced by a multi-link structure, other features are the same as those in Embodiment 1.

[0051] Such as image 3 As shown, the multi-link structure includes a longitudinal swing arm, a transverse swing arm 31, a tie rod 38, a joint arm 33 and a shock absorber, and the longitudinal swing arm, transverse swing arm 31 and joint arm 33 are integrally formed; The longitudinal swing arm and the transverse swing arm 31 are indirectly connected to the vehicle frame through pins; one end of the tie rod 38 is connected to the joint arm through the ball stud 37, and the other end is indirectly connected to the rear beam of the vehicle frame through bolts; the shock absorber 39 The upper part of the shock absorber is provided with a shock-absorbing coil spring 36, the upper end of the shock absorber 39 is connected with the vehicle body, and the lower end is connected with the joint arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com