Cross-shaped parallel robot

A robot and cross-type technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of difficult control of the positional accuracy of the execution part, insufficient rigidity of the overall structure, and high manufacturing costs, reducing the mass of the motion load and improving the motion. The effect of speed, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

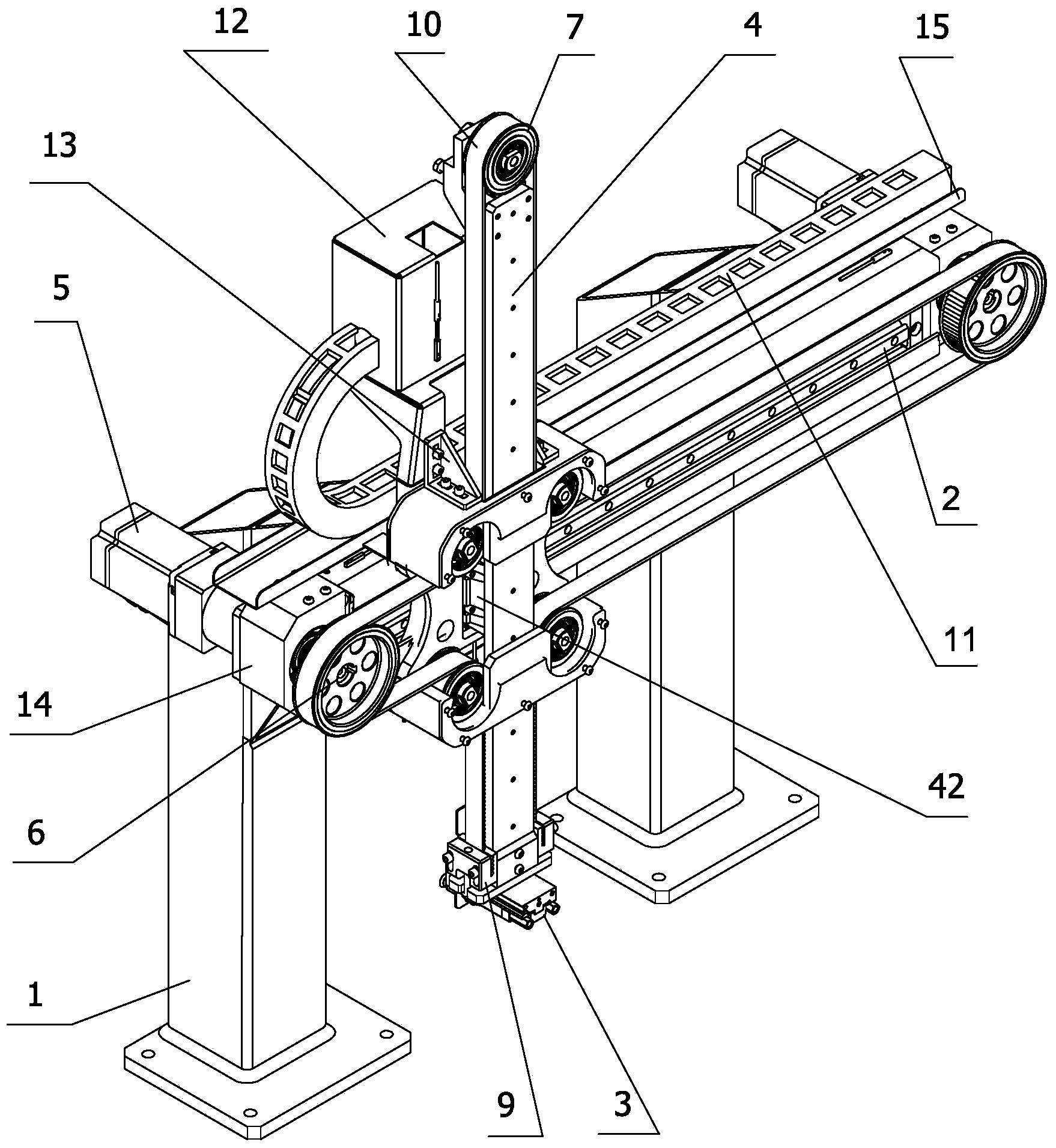

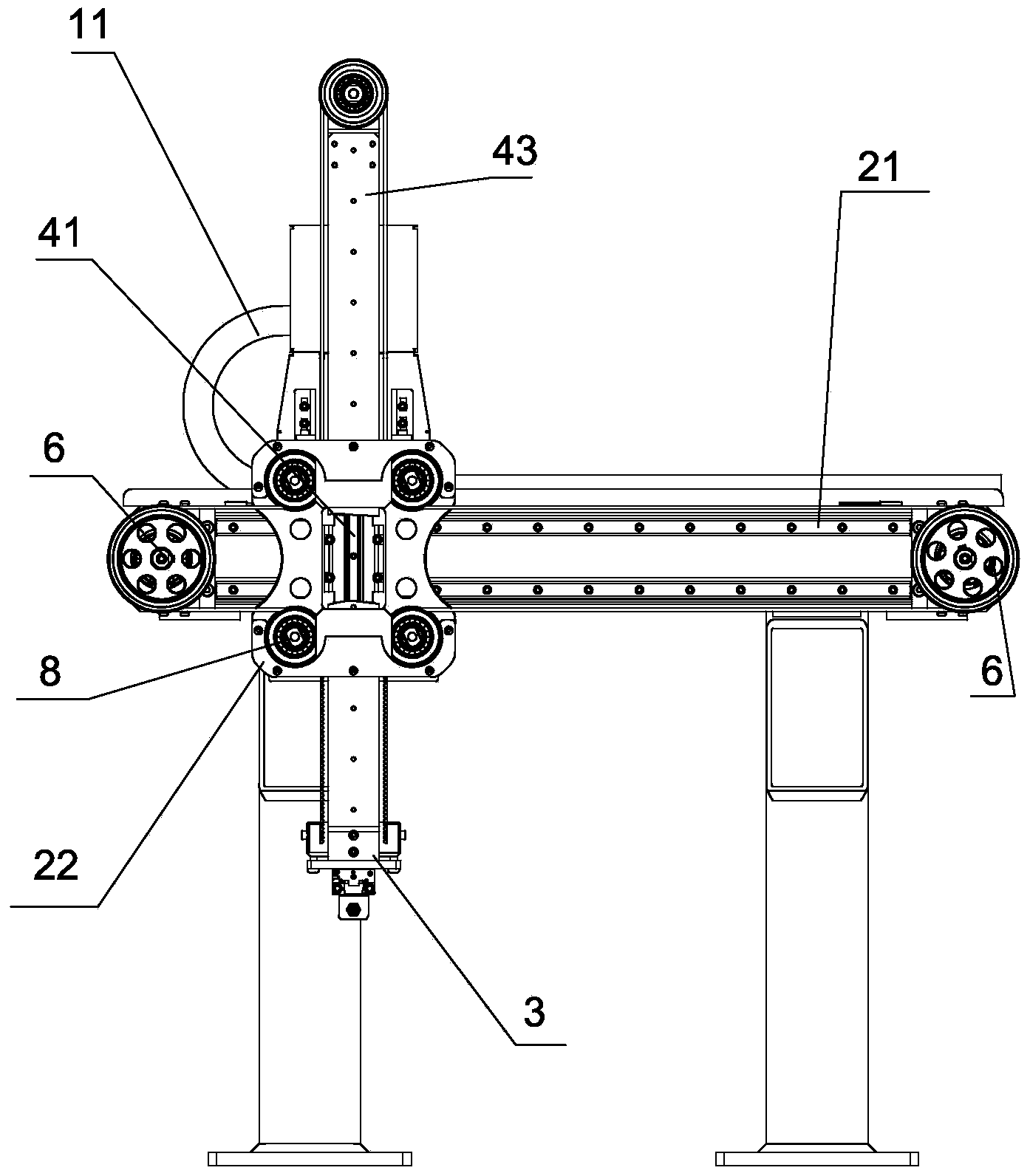

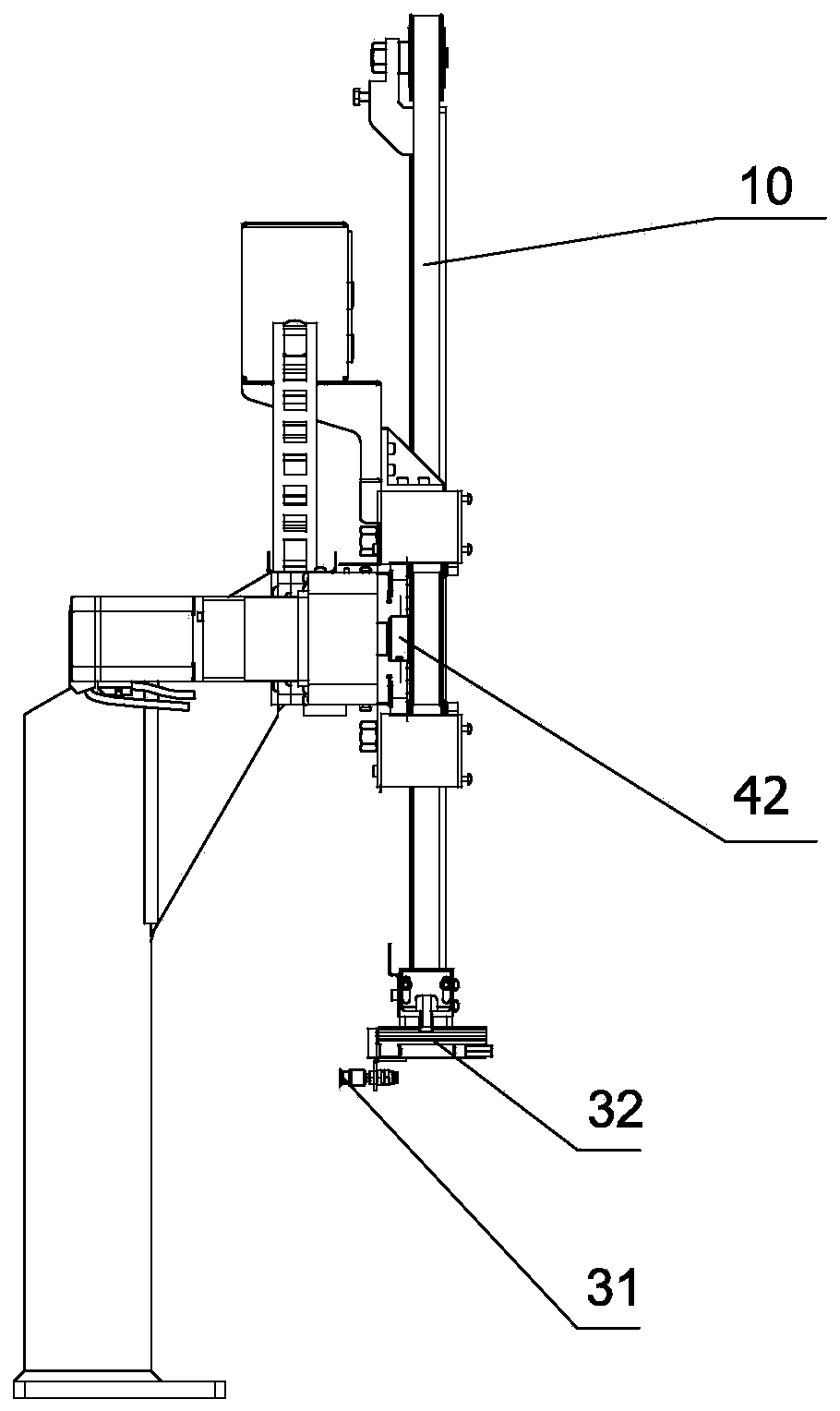

[0021] combine figure 1 —— image 3 As shown, a cross-type parallel robot consists of two columns 1, X-direction assembly 2, Y-direction assembly 3, Z-direction assembly 4, two driving motors 5, two driving synchronous pulleys 6, two driven synchronous Belt pulley 7, four idler pulleys 8, synchronous belt locking block 9, synchronous belt 10, towline 11, towline box 12, towline groove 15 etc. are formed.

[0022] There are two columns 1 arranged at intervals from left to right. The X-direction assembly 2 is composed of an X-direction rail 21 and an X-direction slide plate 22. The left and right ends of the X-direction rail 21 are fixedly connected with the column 1 on the corresponding side. The column 2 is used to support the X-direction rail 21, and the X-direction slide The plate 22 is slidably connected to the X-direction rail 21, preferably, the X-dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com