Drum screen with protecting cover and two kinds of screen meshes

A technology of trommel screen and protective cover, which is applied in the field of trommel screen, can solve the problems of reducing production efficiency and increasing production cost, and achieve the effect of improving work quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be further described below in conjunction with the accompanying drawings.

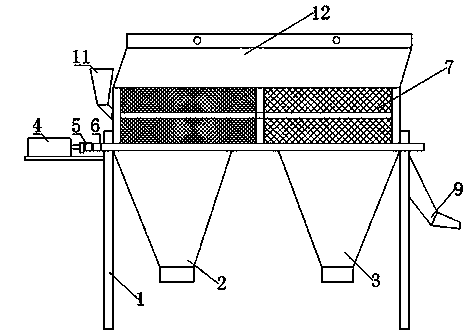

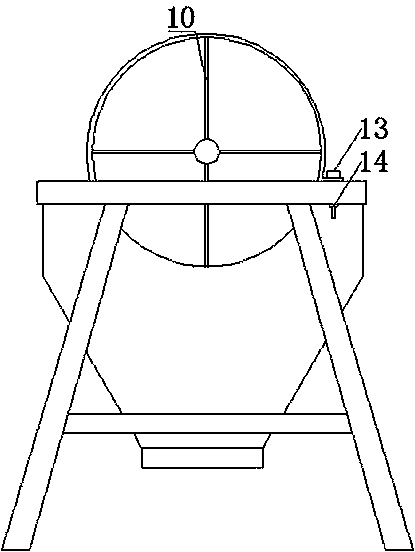

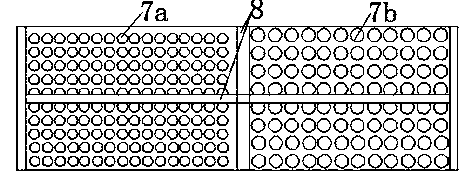

[0017] like figure 1 , 2 As shown in , 3, before the drum screen works, fasten the protective cover 12, fix it with the bracket 1 through bolts 13 and nuts 14, start the drum screen, the material enters the screen body 7 from the feed port 11, and the motor 4 passes through the joint The shaft device 5 drives the screen shaft 6 to move, the rotation of the screen shaft 6 drives the support frame 10 to rotate, and the rotation of the support frame 10 drives the screen body 7 to rotate. When the material enters the screen body 7, it first passes through the first screen part 7a. At this time, the particles are relatively Smaller and pulverized waste materials are thus screened out and discharged from the first discharge port. The fertilizer then passes through the second screen part 7b. Since the size of the mesh of the second screen part 7b is equal to the size of the fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com