Wind and sand proof mechanical filter for rail vehicles

A technology for rail vehicles and wind and sand prevention, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of particles entering with the wind, insufficient dust filtration, and low filtration efficiency, etc., to improve filtration efficiency and promote particles. Settling and filtering, assembly structure and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

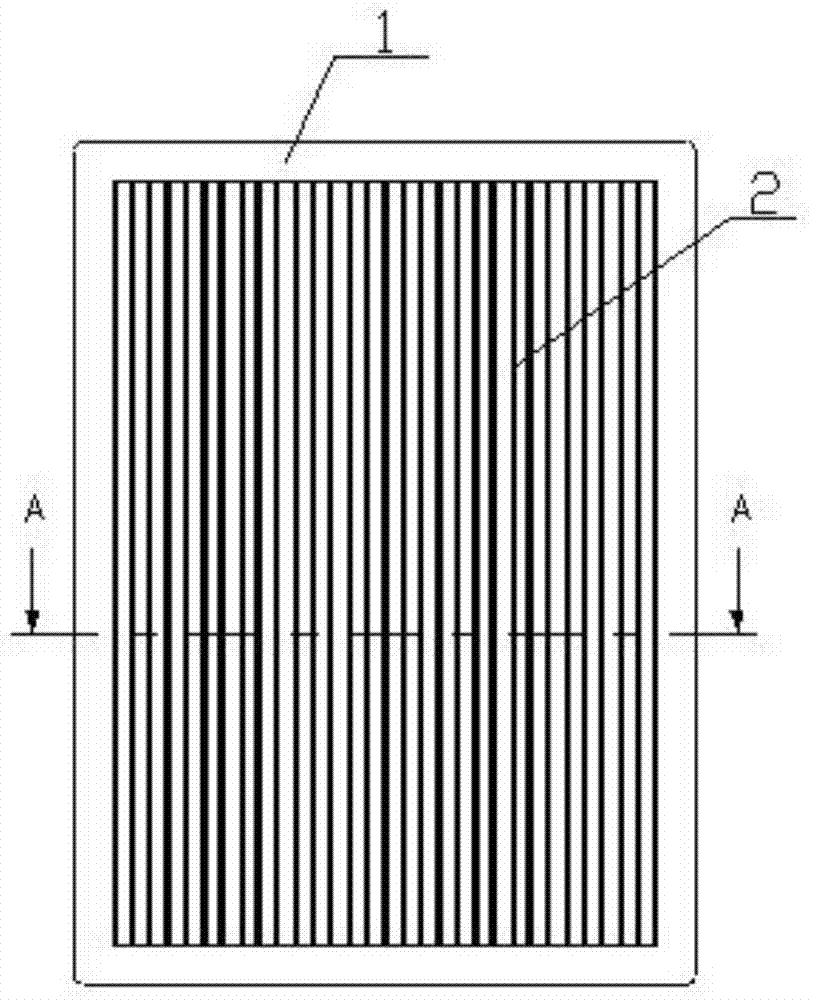

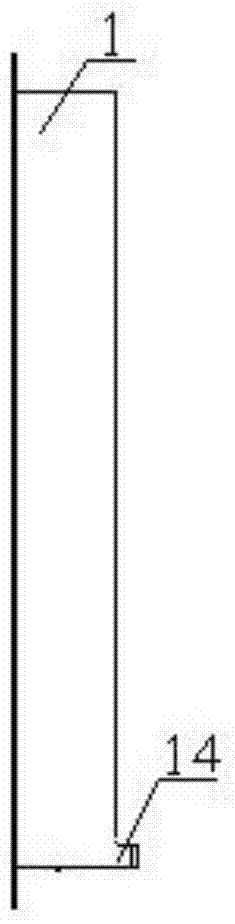

[0036] Such as Figure 1 to Figure 3 As shown, the present invention provides a wind-sand-proof mechanical filter for rail vehicles, comprising a peripheral frame 1 and a plurality of filter units 2 in the middle, the frame 1 is a square structure surrounded by four frames, and the middle has a Space, the filter unit 2 is installed in the accommodation space surrounded by the frame 1, a plurality of filter units 2 are installed in parallel with each other, the number of filter units 2 is determined according to the size of the equipment compartment and the vent of the ventilation system. In this embodiment, ten filter units 2 are installed in the frame 1, and an air flow channel for air flow is formed between every two adjacent filter units 2, and dust, rainwater, snow, etc. in the air pass through the filter units 2 Filtered and deposited in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com