Green walnut peeling machine

A technology of peeling machine and green walnut, which is applied in the field of agricultural machinery, can solve the problems of walnut damage, incomplete peeling of green walnut, high labor intensity, etc., and achieve the effect of increasing the output speed, enhancing the peeling effect, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

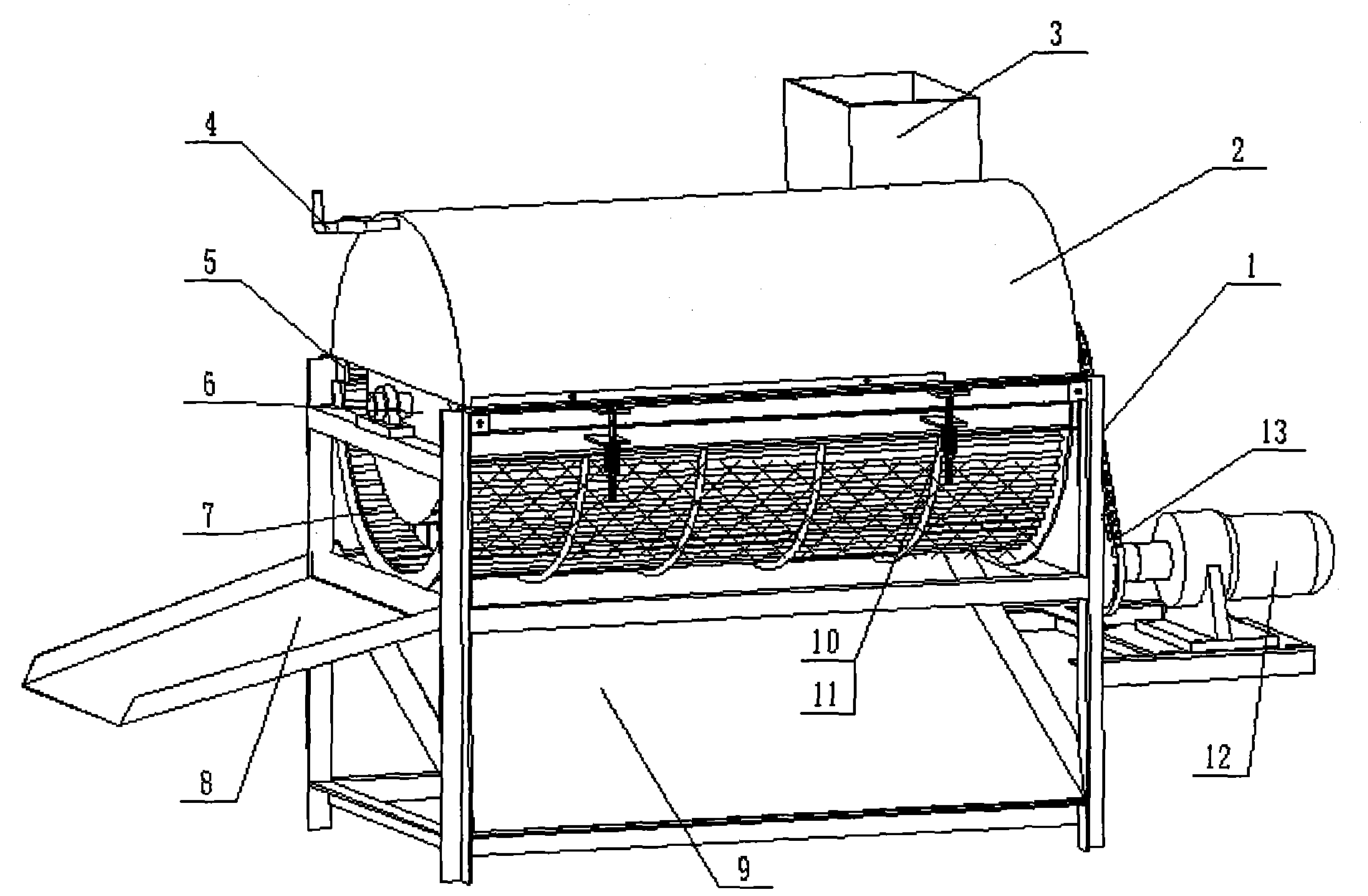

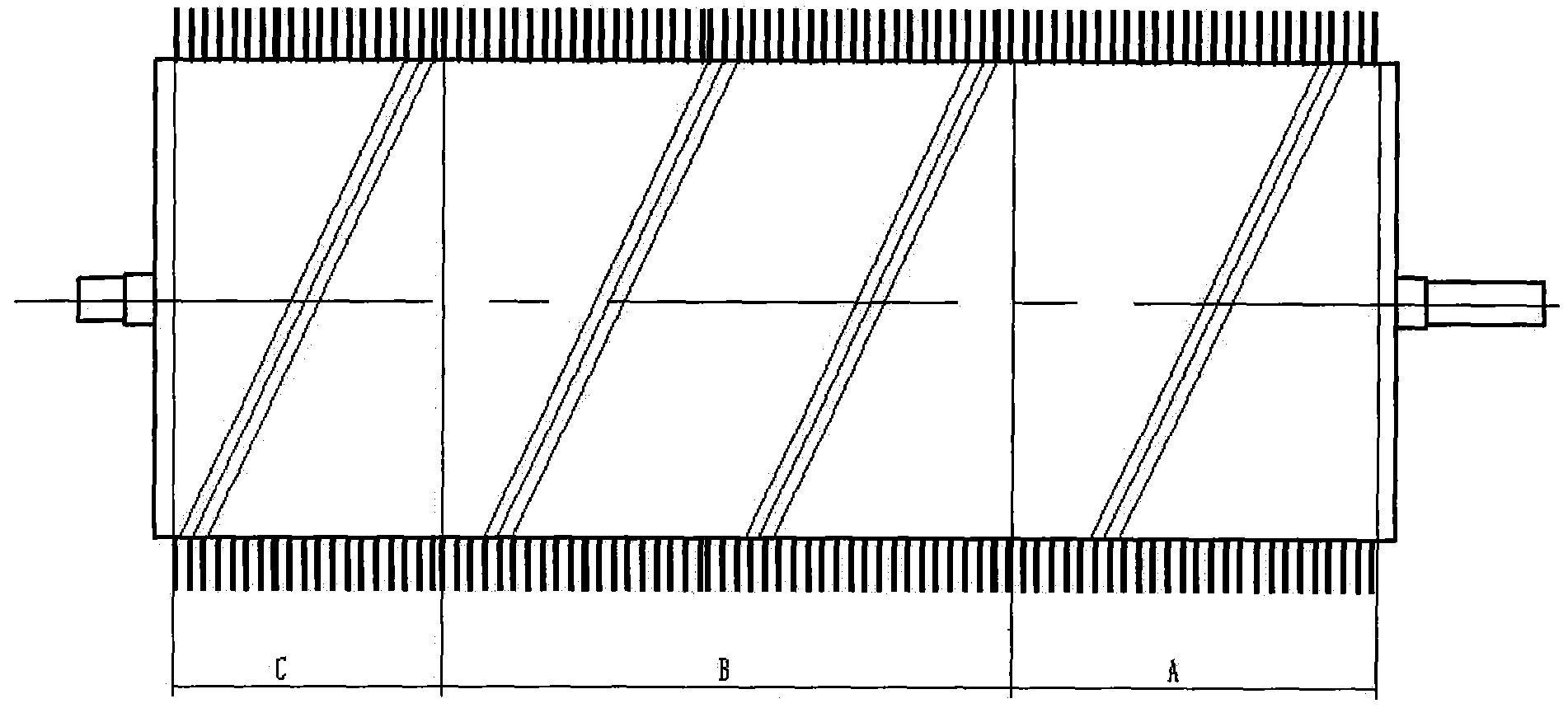

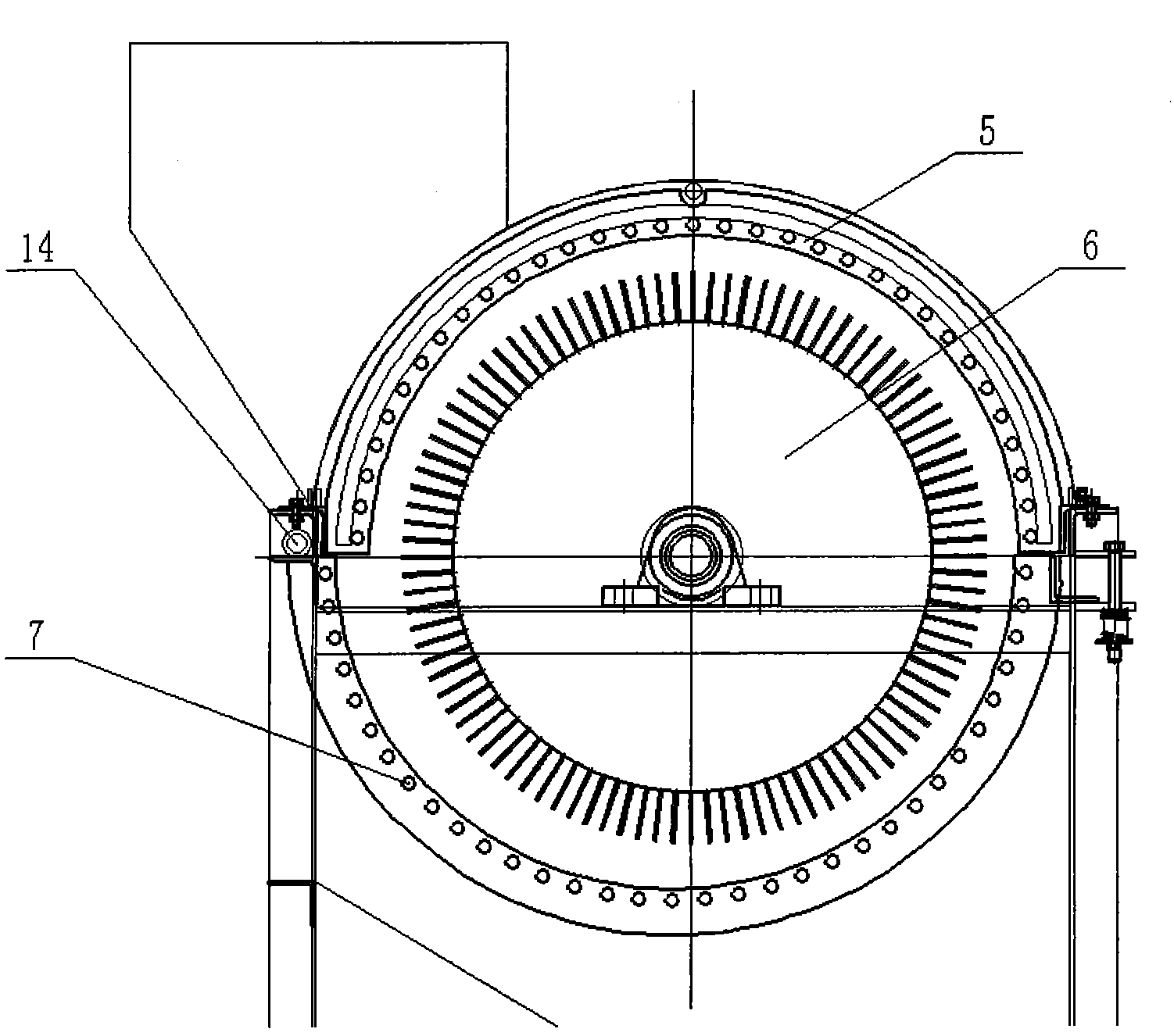

[0016] With reference to accompanying drawing, a kind of green walnut peeling machine of the present invention, it comprises: body 1, machine cover 2, feed hopper 3, spray water pipe 4, upper grid plate 5, spiral brush roller 6, lower grid plate 7, discharge hopper 8, peeling plate 9, spring 10, bolt 11, motor 12, transmission mechanism 13, bearing pin 14, motor 12 is installed at one end of body 1, and the motor power is transmitted to the spiral brush roller 6 of the peeling unit through transmission mechanism 13, so The peeling unit described includes an upper grid plate 5, a lower grid plate 7, a spiral brush roller 6, a bearing pin 14 and a spring 10, and the spiral brush roller 6 is horizontally fixed on the body 1 by a bearing with a seat; the upper grid plate 5 and the lower grid The plate 7 is in the shape of a semi-circular arc, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com