Glasses bracket supporting body

A technology of frame support body and temples, applied in glasses/goggles, optics, instruments, etc., can solve the problems of unfavorable frame versatility, frame size and face mismatch, etc., and achieve simple structure and improved versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

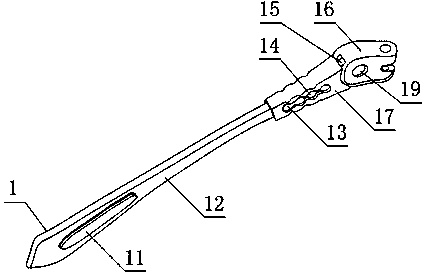

[0025] Figure 1 and figure 2 , a mirror frame support body, comprising a mirror leg body 1, the mirror leg body 1 is sequentially connected in series by an ear hook 12, a block seat 17 and a hinge seat 16;

[0026] The ear hanger 12 is a rod-shaped structure in which a block 13 and a hook are respectively provided at the rear end and the front end, and the block 13 is a columnar protrusion arranged on the side of the ear hanger 12;

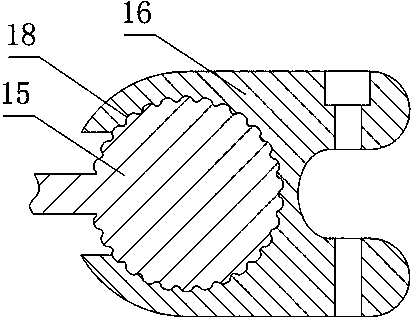

[0027] The block seat 17 is a bar-like structure that is respectively provided with an ear hanger 12 groove and a block groove 14 in its length direction. The ear hanger 12 groove starts from the front end of the block seat 17, and the block groove 14 is located at The side of the block seat 17 is provided with a plurality of width-increasing sections matching the shape of the columnar protrusion along the length direction of the block groove 14, and the rear end of the block seat 17 is also provided with a runner 15, and the runner 15 15 is a d...

Embodiment 2

[0032] This embodiment makes the following further improvements on the basis of embodiment 1: as shown in Figure 1 and figure 2 As shown, in order to facilitate the manufacture of the present invention, and facilitate the sliding of the block 13 in the block groove 14 to realize the smoothness of the block 13 and different width increasing sections, the block 13 is the axis and the length of the ear hook 12 Vertical cylindrical structure. The above structure can be processed by injection molding, and the setting of the shape of the block 13 is beneficial to ensure the stability of its shape in mass production.

[0033] In order to ensure the straightness of the ear hook 12 and the block seat 17 , there is more than one block 13 , that is, at least two blocks 13 on the ear hook 12 are matched with the two width-enlarged sections in the block slot 14 .

[0034] In order to further optimize the above-mentioned effects and simultaneously improve the strength and rigidity of the ...

Embodiment 3

[0037] This embodiment makes the following further improvements on the basis of the above embodiments: figure 1 and figure 2As shown, in order to facilitate the assembly of the block seat 17 and the hinge seat 16, at least one side of the runner 15 is also provided with a rotating shaft 19 whose axis is collinear with the axis of the runner 15, and the runner groove 18 runs through the hinge seat 16 On the upper side or the lower side of the wheel groove 18, a rotating shaft 19 hole that is clearance-fitted with the rotating shaft 19 is also provided. The above structure facilitates the opening of the runner groove 18 to be enlarged by applying tensile stress to the hinged seat 16 solid parts on both sides of the runner groove 18, then inserting the runner 15, and then removing the tensile stress, so that the hinged seat 16 The rebound of the solid part completes the clamping of the runner 15, and completes the connection between the block seat 17 and the hinge seat 16.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com