Straightness Measuring Mechanism for Self-Picking Drill Pipe

A detection mechanism and straightness technology, applied in the field of geological exploration equipment, can solve the problems of high cost, unsafe use, high labor intensity, etc., and achieve the effects of high accuracy, simple structure and reliable detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

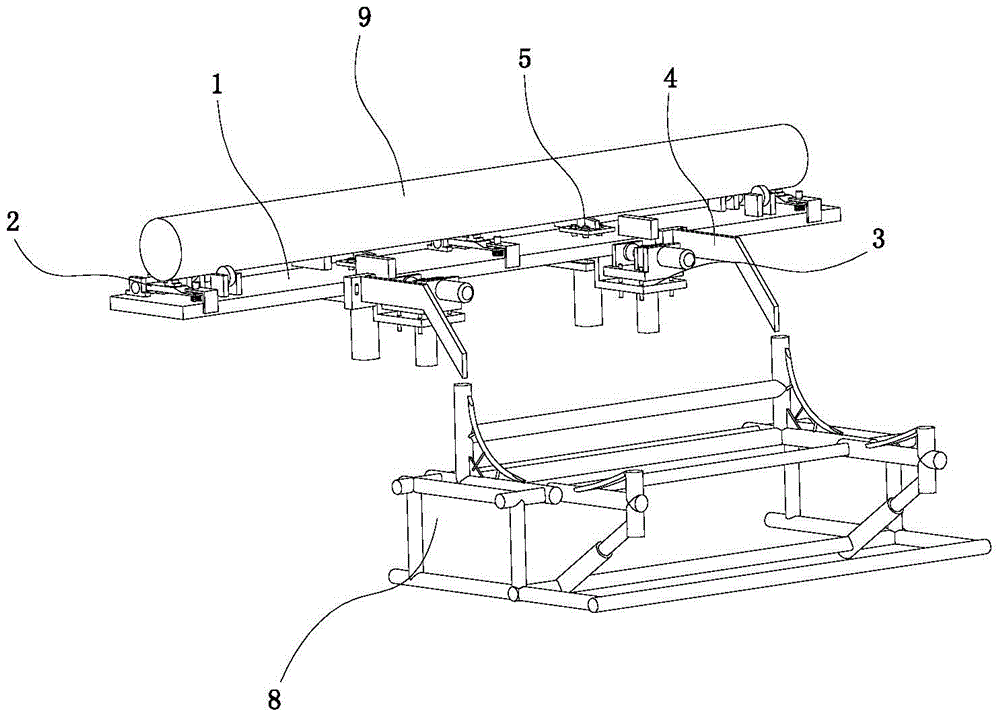

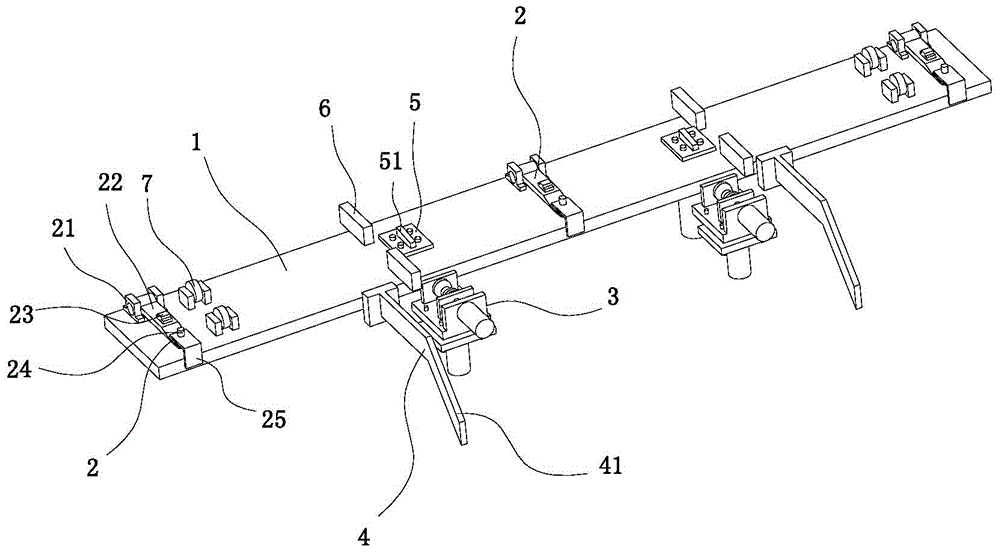

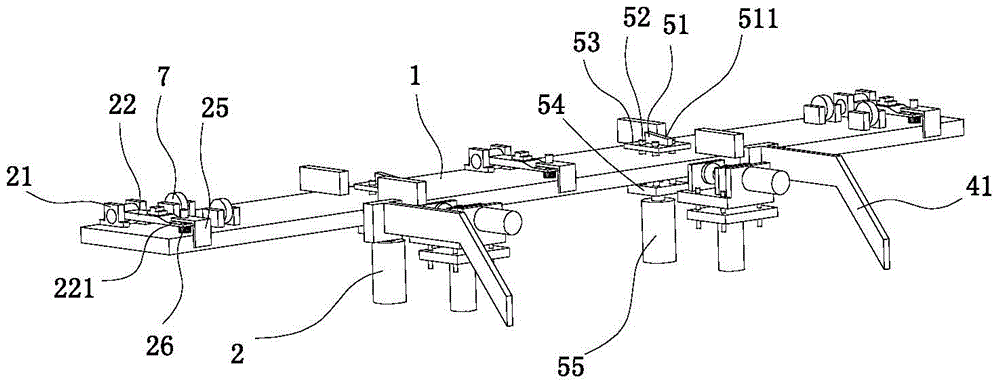

[0032] like figure 1 , figure 2 , image 3 As shown, the straightness detection mechanism of the self-taking drill pipe of this embodiment includes a frame plate 1, and the upper surface of the frame plate 1 is symmetrically equipped with a plurality of contact sensing devices 2, supporting devices and discharging devices 5, The front side of the frame plate 1 is fixedly connected with a material guide plate 4 and a material transfer device 3; the contact sensing device 2 includes at least three groups, and the three groups are evenly distributed on the frame plate 1, and the supporting device and the material discharging device 5 are respectively It includes two groups, which are symmetrically located at both ends of the upper surface of the rack plate 1 in the length direction, and the discharging device 5 is located between the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com