Piston type hydrargyrum optical fiber Bragg grating tilt angle sensor and using method thereof

An inclination sensor, piston-type technology, applied in the direction of instruments, optical devices, measuring devices, etc., to achieve the effect of reducing cross-sectional area, improving inclinometer sensitivity and measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

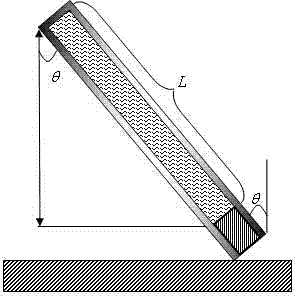

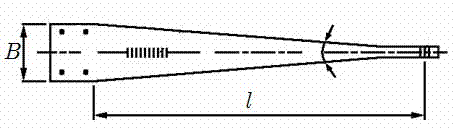

[0044] Embodiment 1: as Figure 1-4 As shown, a piston-type mercury fiber Bragg grating inclination sensor includes mercury column metal shell 1, mercury column 2, mercury column support frame 3, shell 4, optical fiber outlet hole 5, output optical fiber 6, pressure transmission piston 7, dowel rod 8. Optical fiber Bragg grating 9, equal strength cantilever beam 10, cantilever beam support column 11, base 12; wherein mercury 2 is filled in mercury column metal shell 1, mercury 2 is sealed in mercury column metal shell 1 through pressure transmission piston 7, and mercury column The column metal shell 1 is fixed in the shell 4 by the mercury column support frame 3, the shell 4 is welded above the base 12, the lower end of the pressure transmission piston 7 is connected to the upper end of the dowel rod 8, and the lower end of the dowel rod 8 is connected to the cantilever beam 10 of equal strength. At the free end, the fiber Bragg grating 9 is pasted on the upper and lower wall...

Embodiment 2

[0050] Embodiment 2: as Figure 1-4 As shown, a piston-type mercury fiber Bragg grating inclination sensor includes mercury column metal shell 1, mercury column 2, mercury column support frame 3, shell 4, optical fiber outlet hole 5, output optical fiber 6, pressure transmission piston 7, dowel rod 8. Optical fiber Bragg grating 9, equal strength cantilever beam 10, cantilever beam support column 11, base 12; wherein mercury 2 is filled in mercury column metal shell 1, mercury 2 is sealed in mercury column metal shell 1 through pressure transmission piston 7, and mercury column The column metal shell 1 is fixed in the shell 4 by the mercury column support frame 3, the shell 4 is welded above the base 12, the lower end of the pressure transmission piston 7 is connected to the upper end of the dowel rod 8, and the lower end of the dowel rod 8 is connected to the cantilever beam 10 of equal strength. At the free end, the fiber Bragg grating 9 is pasted on the upper and lower wall...

Embodiment 3

[0066] Embodiment 3: as Figure 1-4 As shown, a piston-type mercury fiber optic Bragg grating inclination sensor includes mercury column metal shell 1, mercury 2, mercury column support frame 3, shell 4, optical fiber outlet hole 5, output optical fiber 6, pressure transmission piston 7, dowel rod 8. Optical fiber Bragg grating 9, equal strength cantilever beam 10, cantilever beam support column 11, base 12; wherein mercury 2 is filled in mercury column metal shell 1, mercury 2 is sealed in mercury column metal shell 1 through pressure transmission piston 7, and mercury column The column metal shell 1 is fixed in the shell 4 by the mercury column support frame 3, the shell 4 is welded on the top of the base 12, the lower end of the pressure transmission piston 7 is connected to the upper end of the dowel 8, and the lower end of the dowel 8 is connected to the cantilever beam 10 of equal strength. At the free end, the fiber Bragg grating 9 is pasted on the upper and lower walls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com