Branch air volume self-adjustment based air volume control system

An air volume control system and self-adjusting technology, applied in heating and ventilation control systems, heating and ventilation safety systems, and control inputs involving air characteristics, can solve problems such as low reliability, difficult design, and long design cycle. Achieve the effects of low difficulty in realization, simple and reliable system control, and enhanced versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

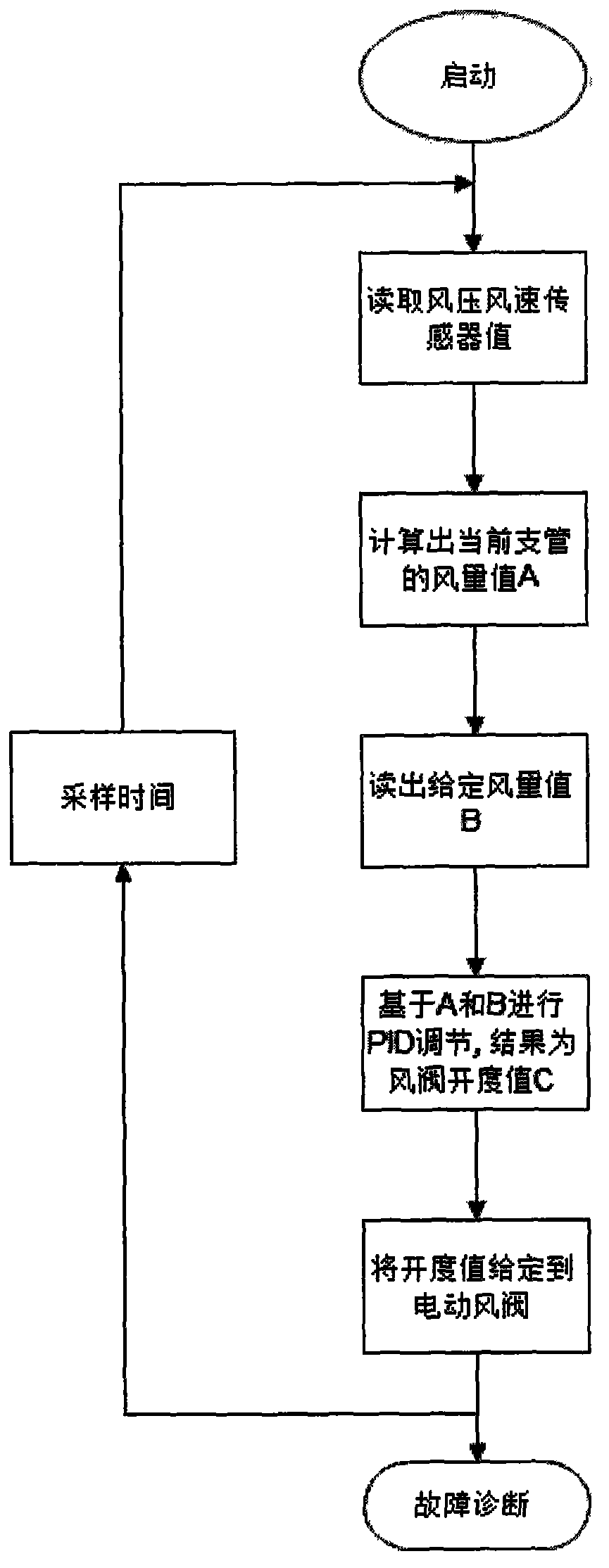

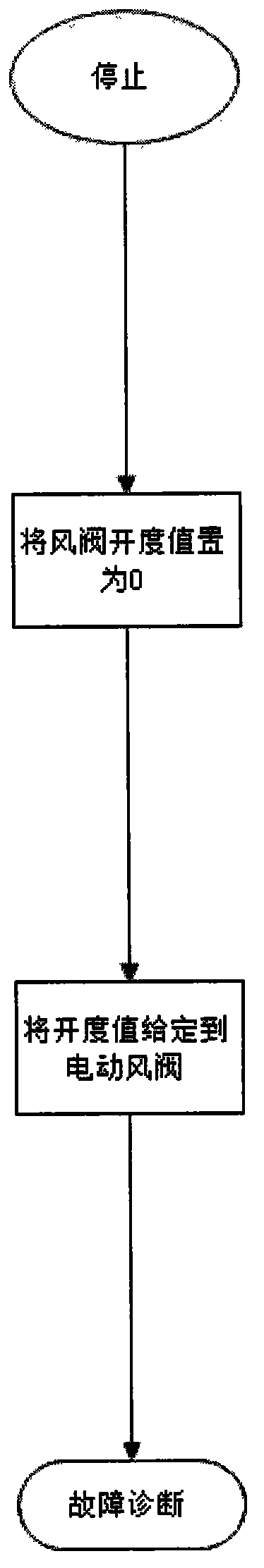

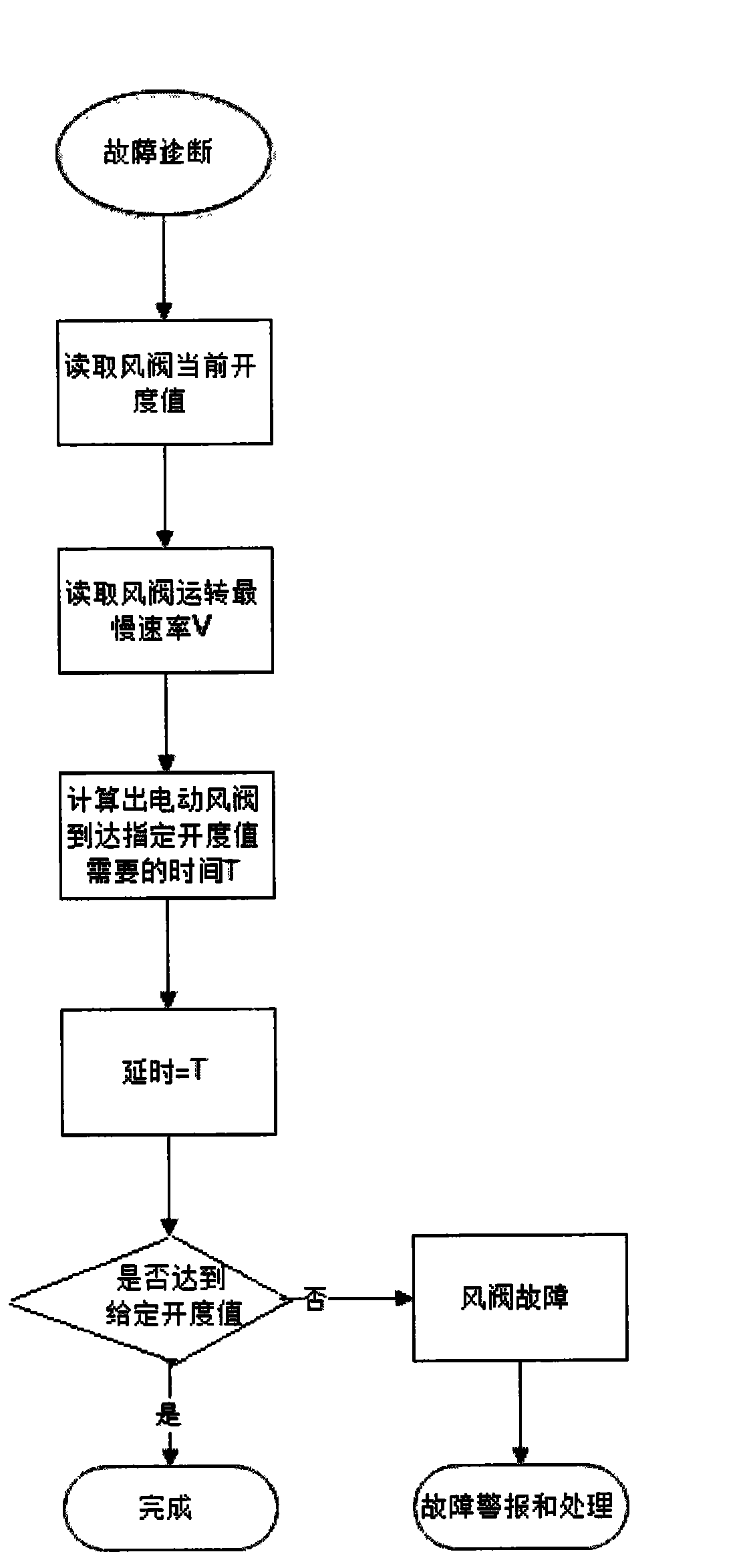

[0026] Please refer to Figure 1 to Figure 3 , the present invention provides an air volume control system based on branch air volume self-adjustment, including: a branch electric air valve installed on a branch road of the air pipe for adjusting the air volume of the branch road; a branch road wind speed and pressure sensor, Installed on the branch road to detect the wind speed and wind pressure of the branch circuit; the branch circuit controller is installed on the electric air valve (for example, installed in the junction box of the electric air valve, or it can be installed near the electric air valve for easy operation, location for maintenance), used to receive a given air volume, and calculate the current actual air volume of the branch according to the wind speed, wind pressure and pipe diameter of the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com