Structure for attaching component to plate-shaped member

A technology for installing plate-shaped components and parts, which is applied in the direction of connecting components, light-weight installation, thin-plate connection, etc., can solve the problems of increased operating hours, damage to ceiling materials, etc., and achieves the effect of preventing accidental falling off and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

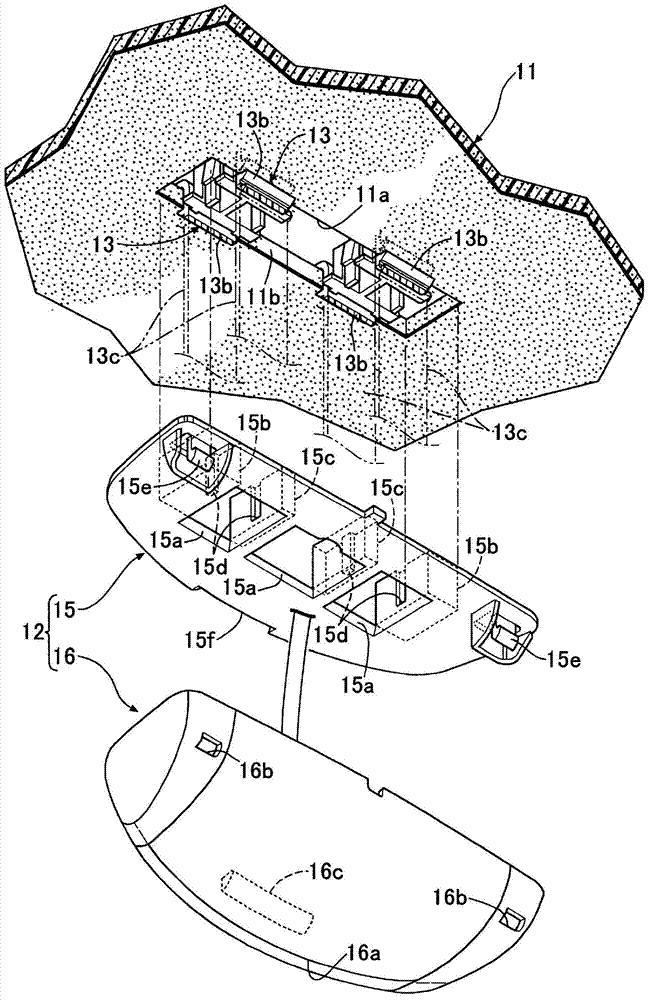

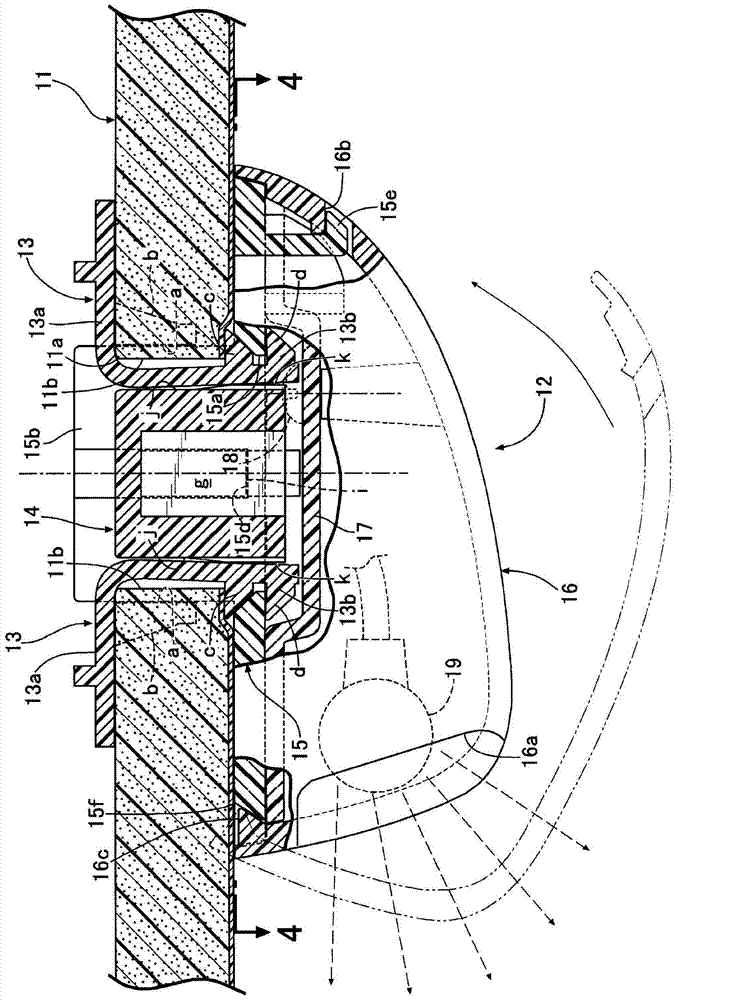

[0038] Below, according to Figure 1 to Figure 9 Embodiments of the present invention will be described.

[0039] Such as figure 1 as well as Figure 9 As shown, the side surface of the cabin of the roof of the automobile is covered with a roof lining 11 made of soft polyurethane foam resin, etc., and a pair of left and right indicators 12, 12 are installed on the roof lining 11 at the rear of the roof. . When the vehicle backs up and enters the garage, etc., if the obstacle sensor installed on the left side of the rear bumper detects an obstacle, the indicator 12 on the left side lights up, and if the obstacle sensor installed on the right side of the rear bumper When the object sensor detects an obstacle, the indicator 12 on the right side lights up. Therefore, the driver can confirm the lighting state of the indicators 12, 12 through the interior rearview mirror, thereby preventing the vehicle from coming into contact with the obstacle. The indicators 12 and 12 are equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com