An adjustable steam turbine wheel inner hole grinding device

A technology for grinding devices and steam turbines, which is applied in the direction of grinding devices, grinding machine tools, and parts of grinding machine tools. It can solve the problems of affecting maintenance frequency and equipment life, labor consumption, and increasing maintenance frequency, etc., so as to avoid poor grinding surface. Influence, benefit, manufacture and installation, and the effect of optimizing the stress situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to fully explain the implementation of the present invention, examples of the implementation of the present invention are provided. These implementation examples are merely illustrative of the present invention and do not limit the scope of the present invention.

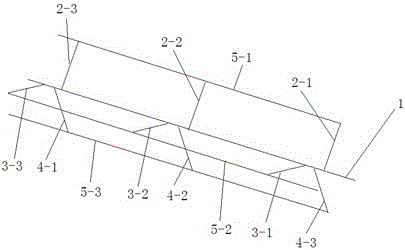

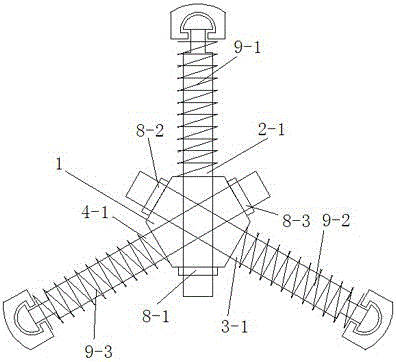

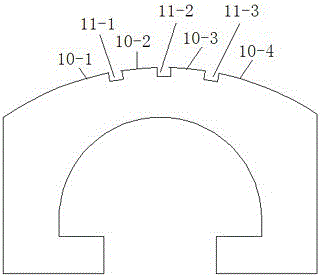

[0011] As attached figure 1 , Attached figure 2 , Attached image 3 , Attached Figure 4 As shown, an adjustable steam turbine wheel inner hole grinding device includes a main shaft 1. The main shaft 1 is connected to a rotating drive device. At least two rows of holes are provided radially along the main shaft 1. The two rows of holes are evenly distributed along the circumference of the main shaft. There are at least two holes in each row. A bolt with a thread on one end passes through the hole and is positioned by a nut. The other end of the bolt is provided with a clamping joint. The abrasive material support rod with a clamping notch is arranged in parallel with the main shaft 1. There are at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com