Auxiliary oil container automatic cleaning machine

An automatic cleaning machine and auxiliary oil technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult cleaning and low efficiency of auxiliary oil containers, and achieve wastewater treatment that is beneficial to environmental protection and saving Water resources, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

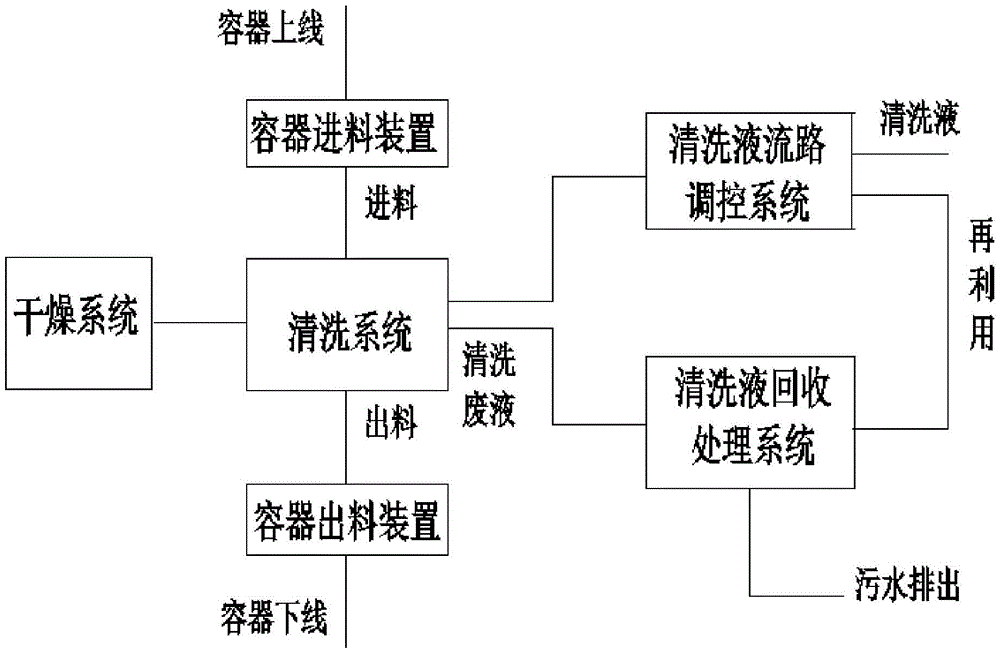

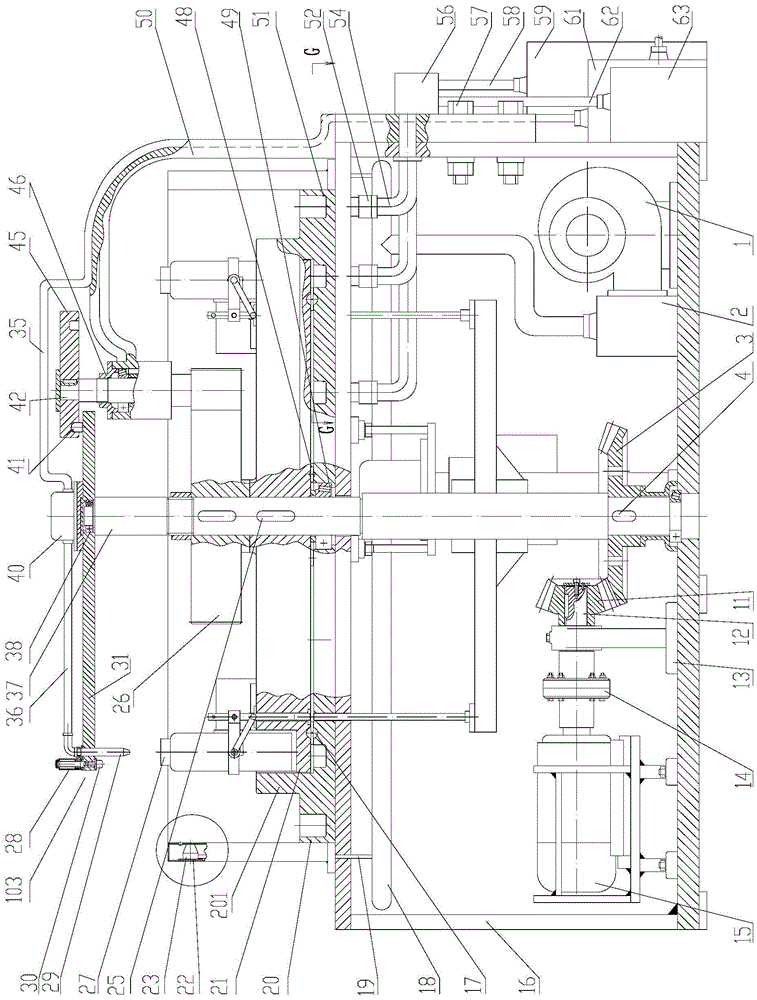

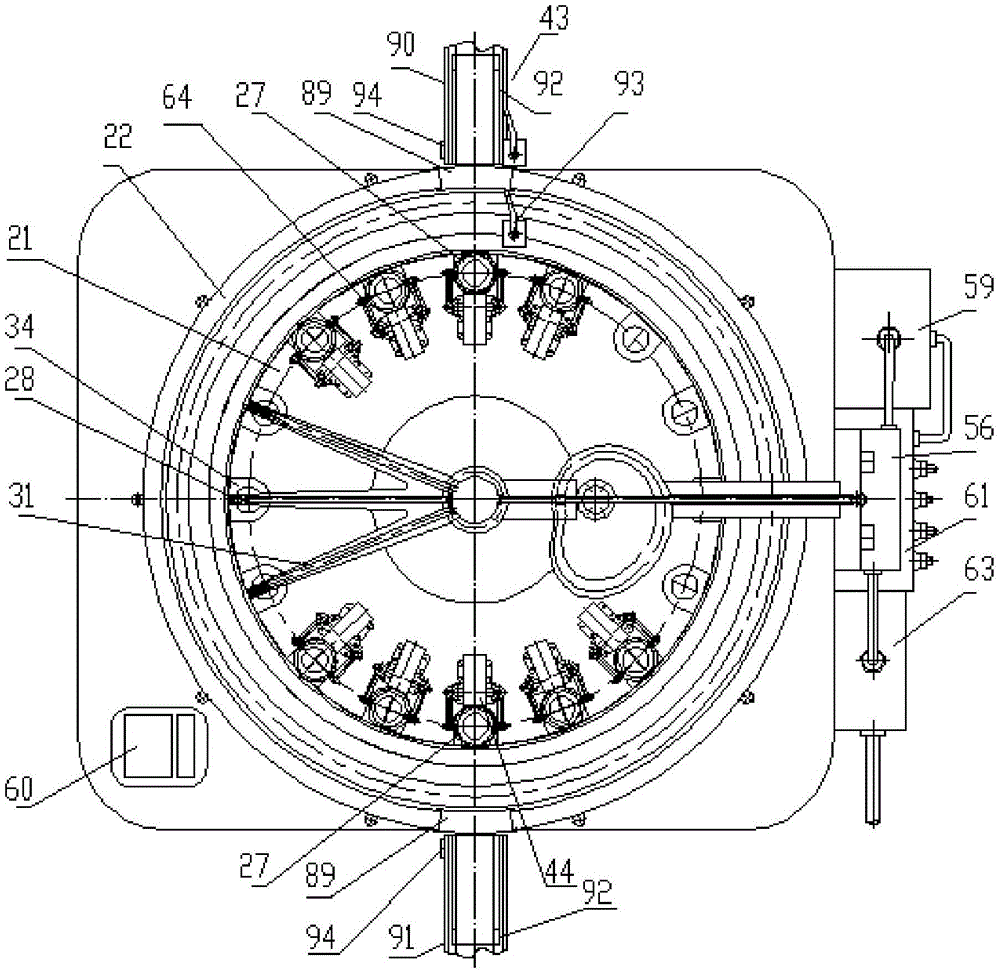

[0084] Such as figure 1 As shown, an automatic cleaning machine for an auxiliary oil container includes a cleaning system, a cleaning liquid flow control system, a drying system, a container conveying system, a cleaning liquid recycling system and a control system. The cleaning system is used to complete the soaking, cleaning, pouring and drying of the container; the cleaning liquid flow control system sets the hydraulic flow and power according to the cleaning requirements of the container to be washed, and the optional cleaning liquid can be a chemical cleaning agent , pure tap water; the drying system blows and dries the container; the container conveying system inputs the container to be cleaned to the cleaning system and outputs the cleaned container; the cleaning liquid recovery and treatment system opens the corresponding waste liquid channel ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com