Gear speed reduction motor

A technology of gear reduction and bevel gear, which is applied in the direction of gear transmission, belt/chain/gear, electrical components, etc., can solve the problems of wasting maintenance time, inconvenient disassembly and assembly, etc., and achieve material cost saving, convenient disassembly and assembly, and small weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

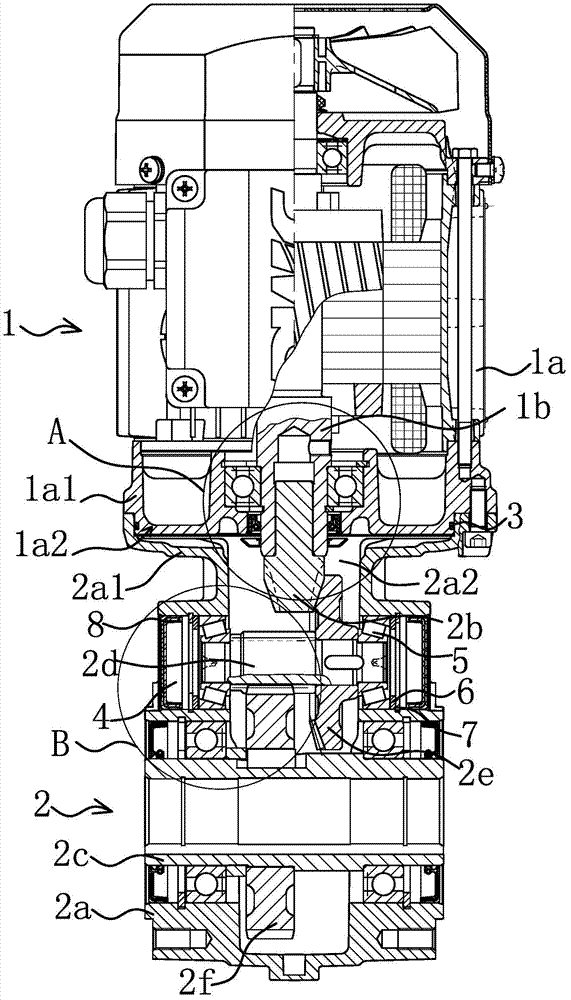

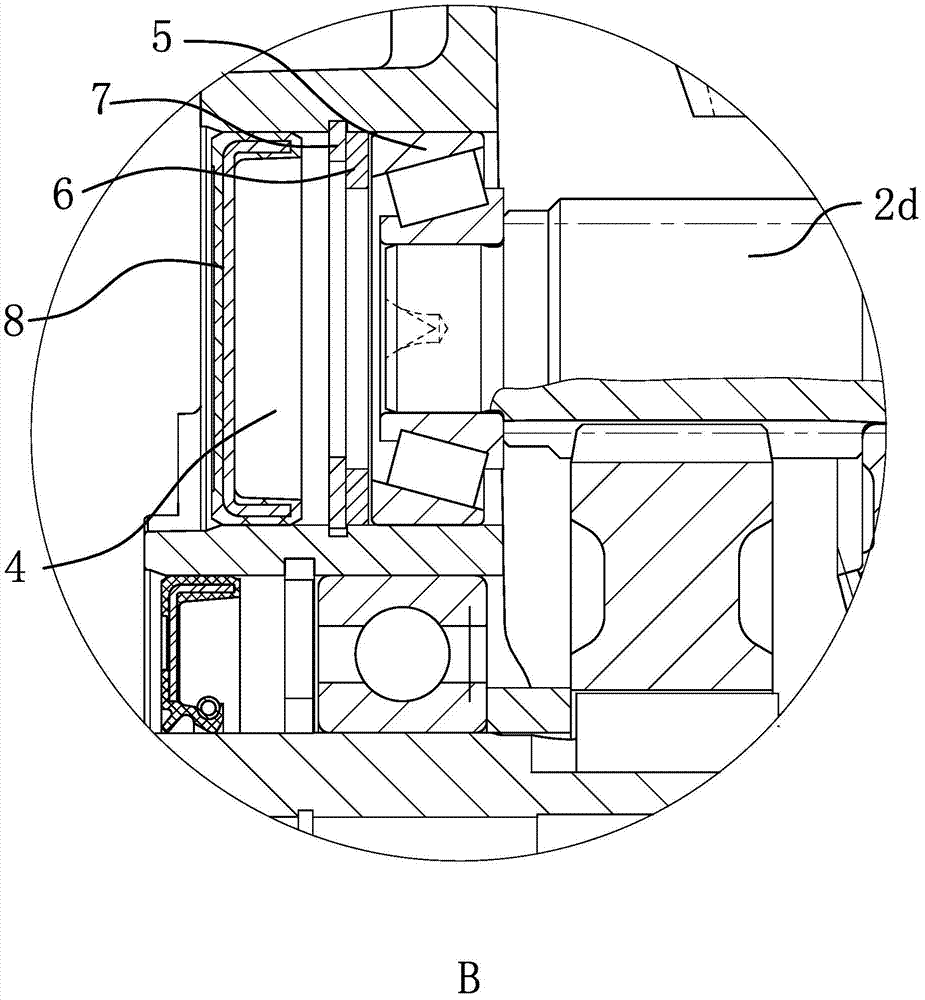

[0040] Such as Figure 1 to Figure 4 As shown, a gear reduction motor includes a motor 1 and a reducer 2; the motor 1 has a motor housing 1a and a motor shaft 1b; the reducer 2 has a casing 2a, a bevel gear input shaft 2b and an output shaft 2c, and the motor The casing 1a is fixedly connected with the box body 2a, the motor shaft 1b is coaxially arranged with the bevel gear input shaft 2b and one end of the motor shaft 1b penetrates into the box body 2a and is fixedly connected with the bevel gear input shaft 2b. The present invention starts from the connection relationship between the motor 1 and the reducer 2, so that one end of the motor shaft 1b directly penetrates into the box 2a and is fixedly connected with the bevel gear input shaft 2b. However, in an ordinary geared motor, the motor shaft 1b usually needs to be connected with the input shaft in the box body 2a through a complex gear connection structure. Compared with ordinary gear reduction motors, this saves the c...

Embodiment 2

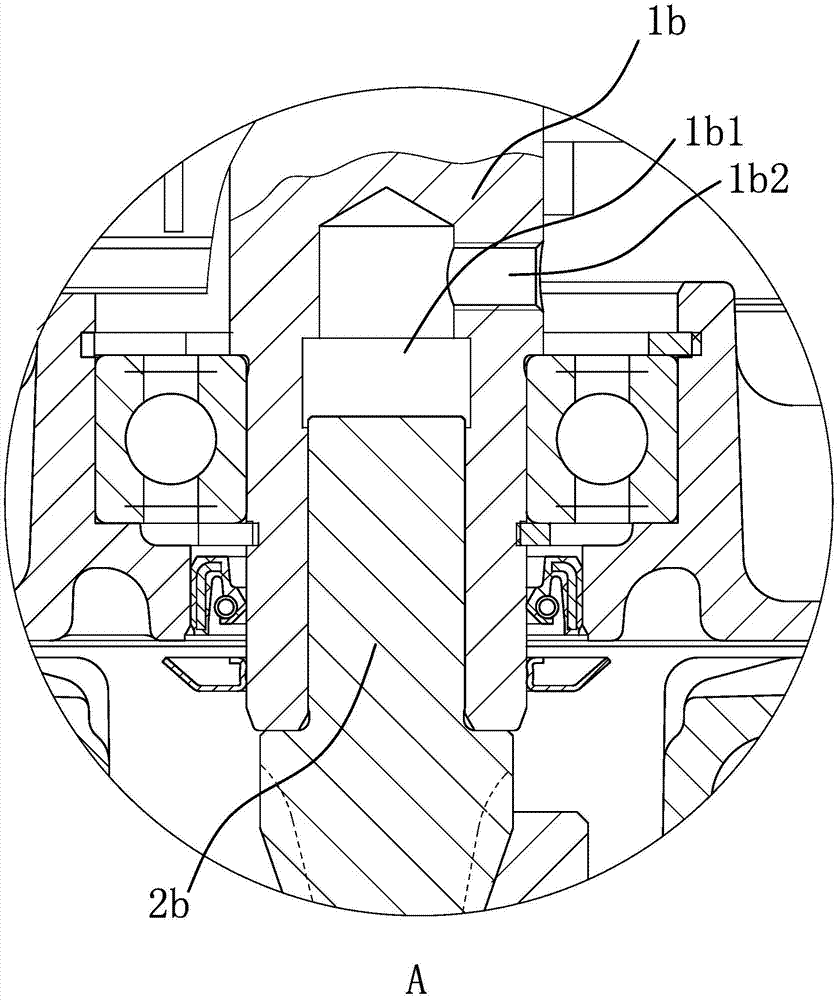

[0050] Such as Figure 5 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, the difference lies in: a shaft hole 1b1 coaxial with the bevel gear input shaft 2b is provided on the shaft end face of the bevel gear input shaft 2b , The motor shaft 1b penetrates into the shaft hole 1b1 and tightly fits with the shaft hole 1b1, so that the same effect can be achieved. And make the shaft hole-1b1 depth of the bevel gear input shaft 2b greater than the length of the motor shaft 1b extending into the shaft hole-1b1, in addition, there is also a hole on the outer surface of the bevel gear input shaft 2b that communicates with the bottom of the shaft hole-1b1 The hydraulic connection hole 1b2. Similarly, threads are provided on the wall of the hydraulic connection hole 1b2 to facilitate screwing in of the hydraulic nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com