A Method of Determining the Depth of Sliding Slabs in Coal Wall and Its Slipping Risk

A dangerous and slipping technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of no detection method for predicting the risk of slippage in the depth of the coal wall, and the depth difference between the predicted values is relatively high. Problems such as large, single consideration factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0023] Implement a kind of method that the present invention provides to determine the depth of the coal wall slip sheet side and the risk of slip thereof, and its described method is to carry out according to the following steps:

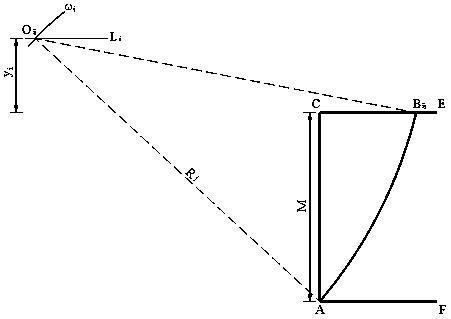

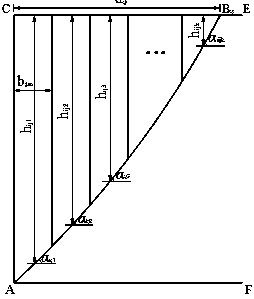

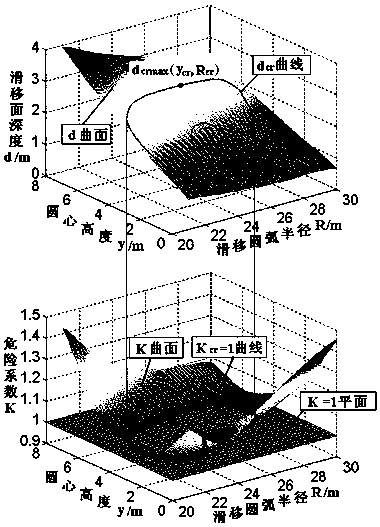

[0024] Step 1, such as Figure 5 As shown, CE is the roof of the mined coal seam, AF is the floor of the mined coal seam, AC is the coal wall of the working face, the height is 6.2m, and the distance from CE above the roof CE is y 3 = 4m draw a straight line L parallel to CE 3 , with A as the center, radius R 3 =25m as arc ω 3 and straight line L 3 Intersect at point O 33 , with O 33 as the center of the circle, O 33 A=R 3 =25m is the radius and make an arc and the roof CE intersect at point B 33 , arc 33 for y 3 =4m and R 3 =25m determined slip surface S 33 , and then take the height y from the center of the circle to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com