Method and system for selecting cutting parameters based on machining features and automatically setting parameters

A technology of processing characteristics and process parameters, applied in special data processing applications, electrical digital data processing, instruments, etc., can solve the problems of poor versatility of the database system, input error information, low work efficiency, etc., to achieve good versatility, Avoid misoperation, good integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

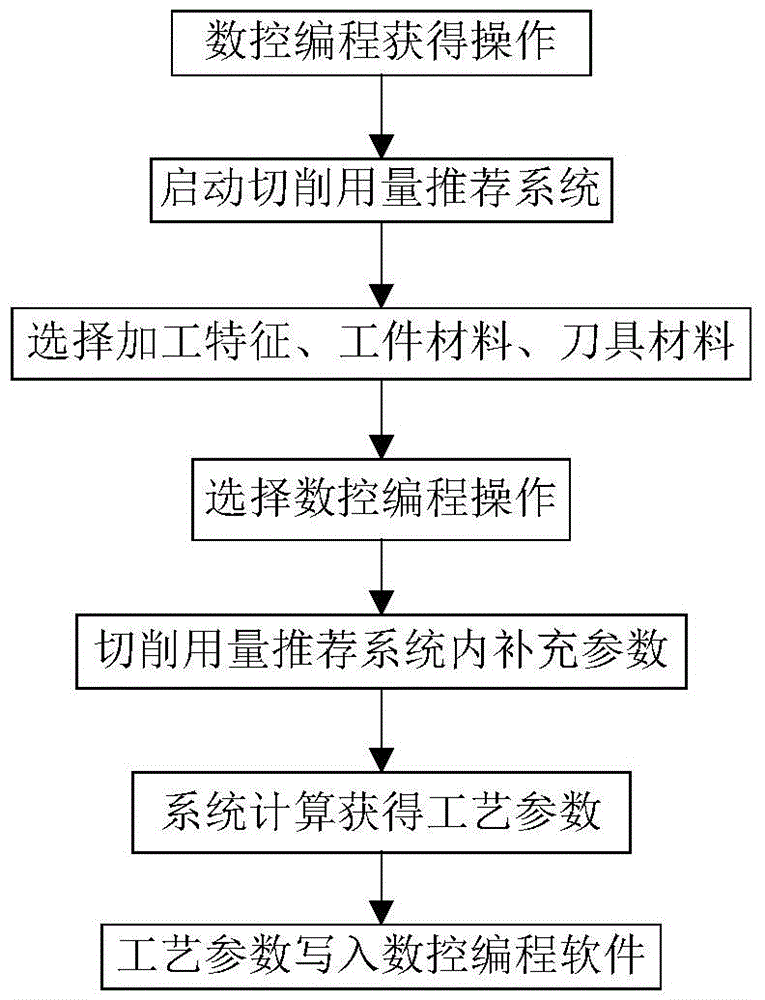

[0078] Such as figure 2 As shown, the method of selecting cutting parameters based on processing characteristics and automatically setting parameters, in operation, specifically: NC programming acquisition operation; starting the cutting parameter recommendation system; selecting processing features, workpiece materials, and tool materials; selecting NC programming operations; cutting The supplementary parameters in the system are recommended for dosage; the process parameters are obtained by system calculation; the process parameters are written into the NC programming software.

[0079] Taking groove milling features as an example, an example of selecting and automatically setting cutting parameters based on machining features in the NC programming software PRO / E is given below.

[0080] (1) As attached Figure 6 As shown, the operation is obtained through PRO / E CNC programming. Set tool parameters, process parameters such as feed speed and spindle speed are to be set, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com