Semiconductor chilling plate control device and surveillance camera

A technology for monitoring cameras and control devices, applied in temperature control, non-electric variable control, control/regulation systems, etc., can solve the problems of unfavorable cooling module volume, increase the number of relays, small layout, etc. The effect of long service life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

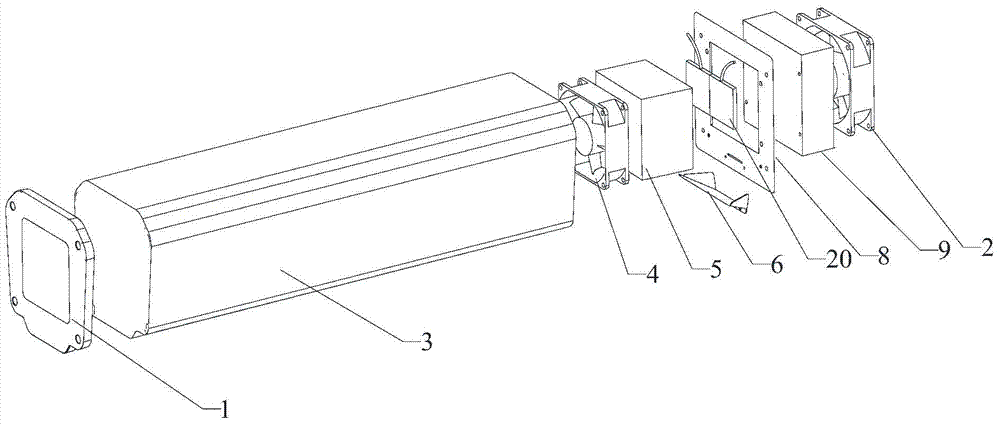

[0022] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0023] The most critical idea of the present invention is to use the DC motor driver chip 40 with adjustable output current to drive the semiconductor cooling chip 20 , so as to effectively prolong the service life of the semiconductor cooling chip 20 .

[0024] Please refer to figure 2 , a semiconductor cooling chip control device, including a temperature sensor 10, an MCU30, a DC motor drive chip 40 and a semiconductor cooling chip 20;

[0025] The control input terminals of the temperature sensor 10 and the DC motor driver chip 40 are respectively connected to the MCU 30, and the output terminals of the DC motor driver chip 40 are connected to the semiconductor cooling chip 20;

[0026] The MCU 30 is used to control the DC motor drive chip 40 to output DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com