Method and device for measuring dynamic stiffness of griffe support connecting system of heald griffe

The technology of a measuring device and a connecting system is applied in the field of measuring the dynamic stiffness of the connecting system of the heddle-lifting knife-lifting support, which can solve the problems of small dynamic damping, reduced operating quality of the opening system, and reduced weaving efficiency, and achieves the reduction of dynamic damping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

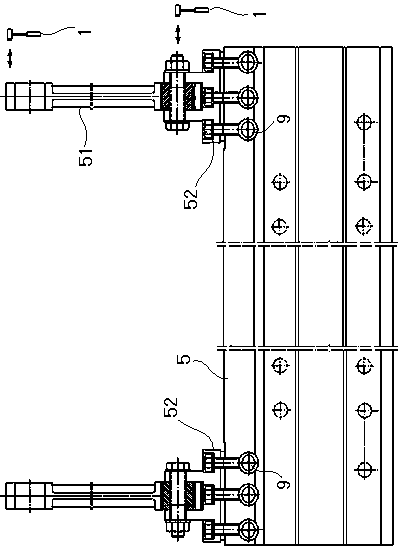

[0036] refer to figure 1 As shown, a method for measuring the dynamic stiffness of the heald-lifting knife-lifting support connection system, the signal generator in the signal analyzer 4 applies a sine signal to the force hammer 1, and the force sensor 2 is installed on the force hammer 1, and the force hammer 1 is used to strike The heald lifting knife 5 outputs a signal through the force sensor 2 while knocking, and the output signal of the force sensor 2 is input to the signal analyzer 4 through the charge amplifier 3 .

[0037] refer to Figure 8 Said, the said heald lifting knife 5 is provided with an acceleration sensor 6a, said acceleration sensor 6a gets the response signal of the connection part of the heald lifting knife 5 and the lifting knife support after the force hammer 1 strikes, and the response signal is input thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com