In-ground type tap water pipeline leak detection device and detection method

A leak detection device and water pipeline technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of not being able to punch many holes at will, low detection accuracy, long electrode wires, etc., and achieve the layout method Flexible, high detection accuracy, simple installation and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

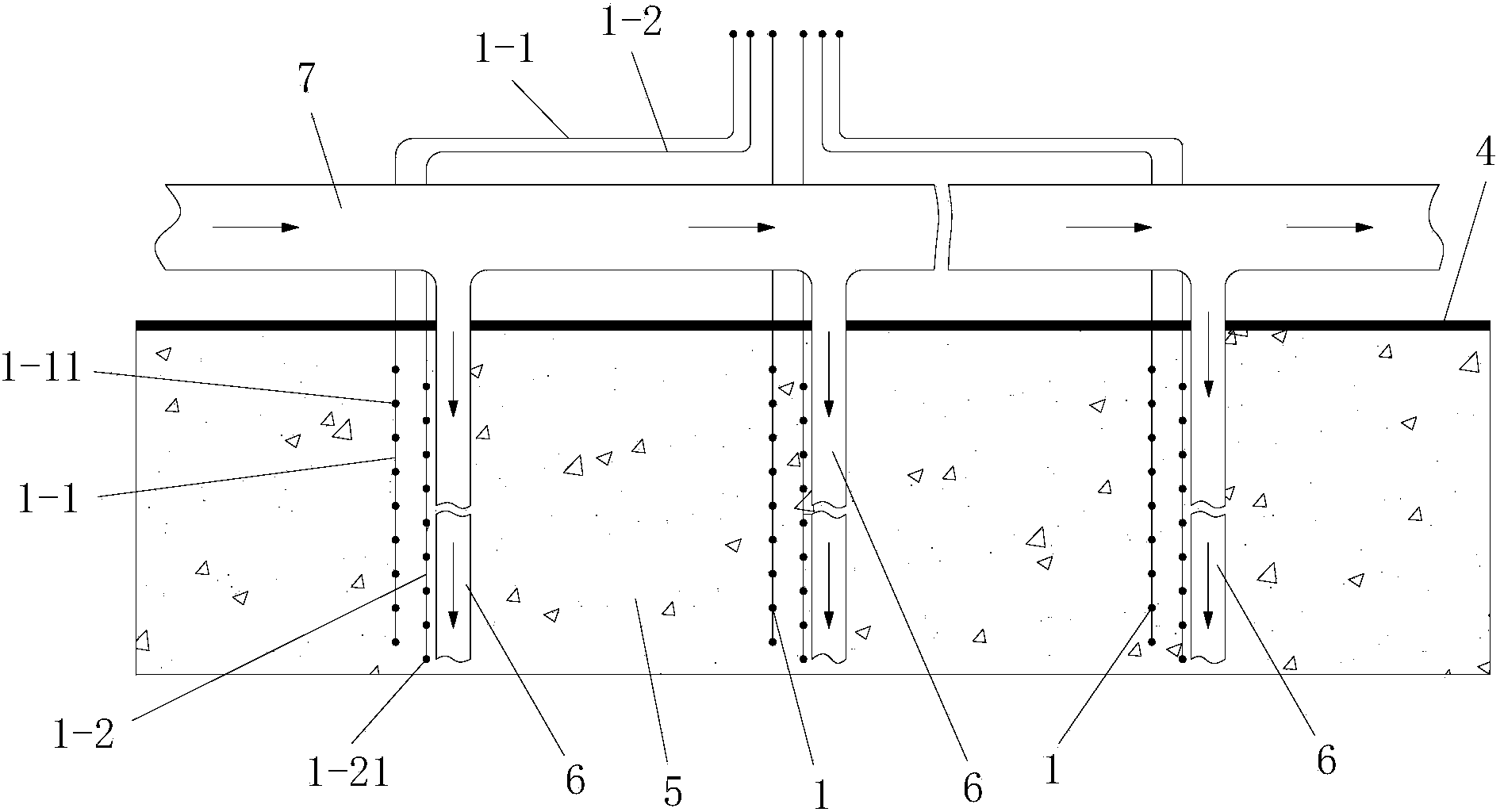

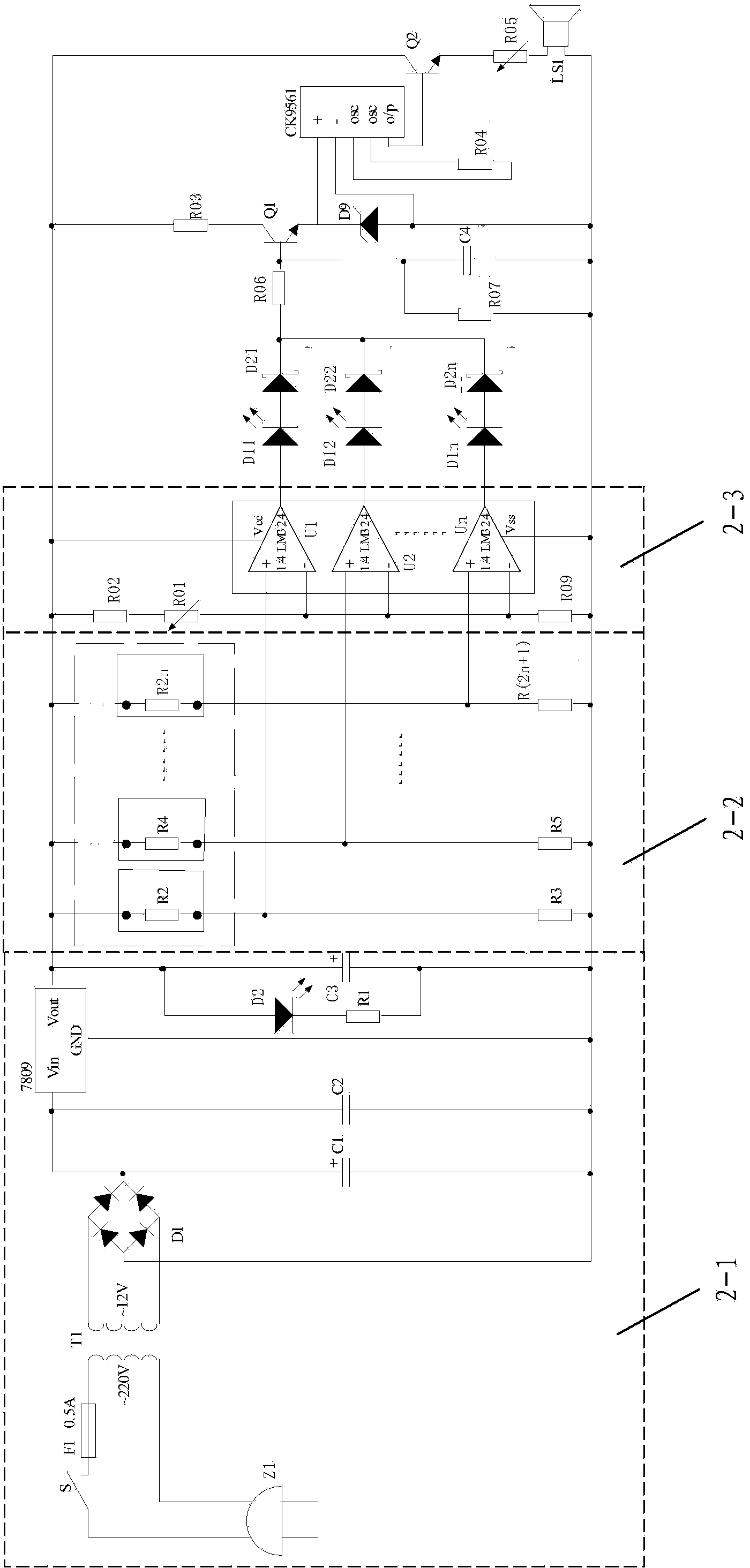

[0038] Such as figure 1 , figure 2 A buried tap water pipeline leak detection device shown includes a leak probe 1 buried in a water leakage detection area and a leak detection circuit 2 connected to the leak probe 1. The leak probe 1 is for the layout position A humidity detection probe that detects the soil humidity at the location. The leak probe 1 includes two wires arranged in parallel and coated with an insulating layer on the outside. The two wires are respectively a first wire 1-1 and a second wire 1-2. The first wire 1 A plurality of first conductive points 1-11 are arranged on -1 from front to back, and the first conductive points 1-11 are exposed points formed after removing the insulating layer outside the first wire 1-1. A plurality of second conductive points 1-21 are arranged on the second wire 1-2 from front to back, and the second conductive points 1-21 are formed after removing the insulating layer outside the second wire 1-2. Get naked. The plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com