A double-coil lever type block brake

A brake, double coil technology, applied in the direction of brake actuators, gear shifting mechanisms, mechanical equipment, etc., can solve the problems of high cost, hidden dangers, large brake volume, etc., to reduce material costs, small size, braking The effect of a wide range of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

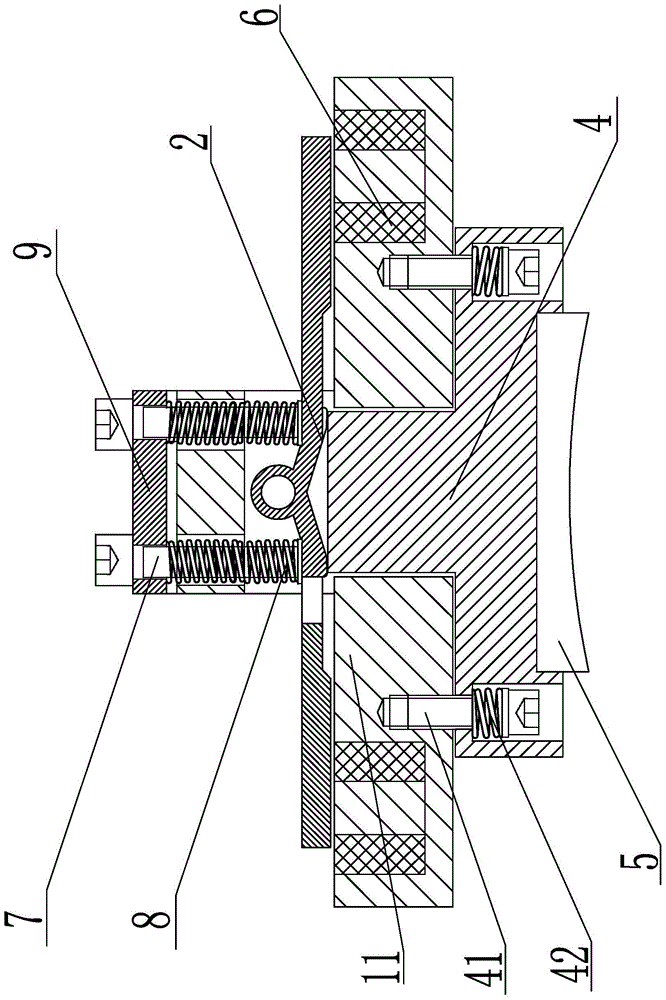

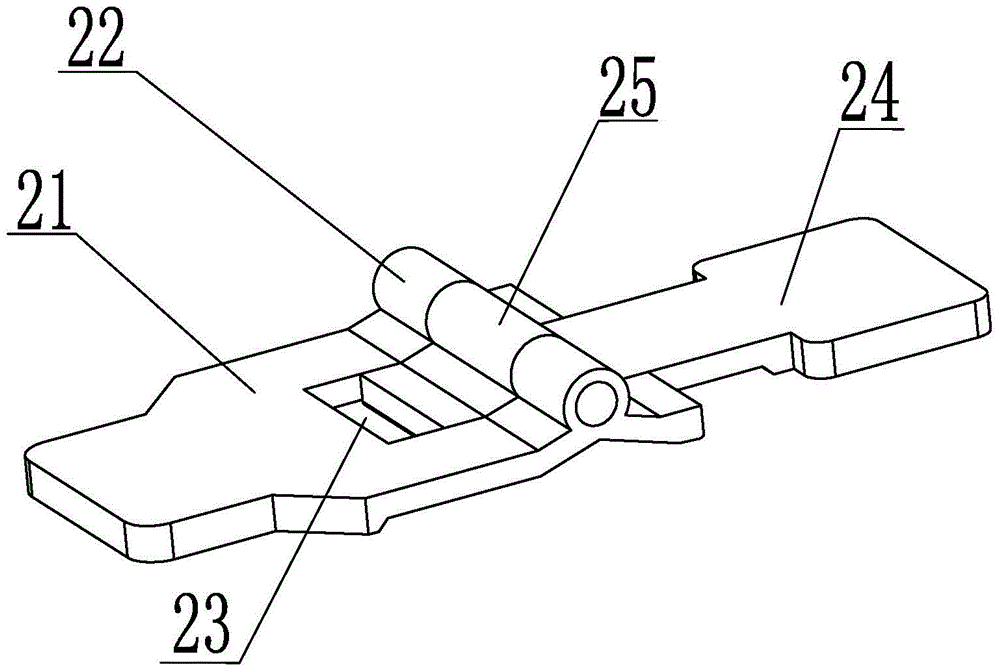

[0017] Such as figure 1 , figure 2 and image 3 A double-coil lever type block brake shown includes a brake body 1, a moving plate 4 and a friction plate 5, the friction plate 5 is fixed on the lower surface of the moving plate 4, and the middle upper surface of the brake body 1 A first protruding block 12 is provided, and the middle part of the first protruding block 12 is provided with a notch with an opening facing downward, and a pressure plate 9 is fixed above the first protruding block 12 by first bolts; the brake main body 1 The lower part is the static plate 11, the two ends of the static plate 11 are provided with grooves, and the induction coil 6 is fixed in the groove; the induction coils are arranged at both ends of the static plate, making full use of the space of the static plate and obtaining maximum braking fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com